Advanced Efficient Energy Robotics

Advantages of Advanced Efficient Energy Robotics:

1,Efficient everyday welding supplies aeer uses the most advanced technology and design, can efficiently complete the work, improve production efficiency.

2,Precision miller 350p manual aeer can be accurately controlled and positioned with the miller 350p manual, and can work in a variety of complex environments with high precision.

3,Energy-saving best 110v mig welder aeer adopts intelligent energy-saving technology with the best 110v mig welder, which can reduce energy consumption and is friendly to the environment.

4,Aeer uses sustainable energy and materials, reduces environmental burden, and meets the sustainable development requirements of modern society.

Advanced Efficient Energy Robotics:

Advanced Efficient Energy Robotics is a cutting-edge technology that is revolutionizing the manufacturing industry. They are highly efficient, precise, and energy-saving robots that use intelligent energy-saving technology to reduce energy consumption and promote a sustainable environment.

To fully leverage the capabilities of Advanced Efficient Energy Robotics, welding professionals rely on superior products like Everyday Welding Supplies, Miller 350p Manual, and Best 110v Mig Welder. These products have been designed and manufactured to enhance the performance of welding robots and to ensure that they deliver high-quality results.

The Miller 350p Manual guides operators in programming and controlling Advanced Efficient Energy Robotics with precision and ease. With pinpoint accuracy, these robots can perform their operations within a wide range of complex industrial environments.

Everyday Welding Supplies provides welders with the necessary tools and equipment to support the work of Advanced Efficient Energy Robotics. From welding guns to protective gear, these supplies are essential in combining the capabilities of welding robots with human expertise to consistently maintain high-quality output levels.

Finally, Best 110v Mig Welder brings Advanced Efficient Energy Robotics to life, providing operators with the technology to easily control and program their robots. Welders can easily adjust welding settings and fine-tune their robotic operations to achieve the highest levels of efficiency and precision.

In summary, Advanced Efficient Energy Robotics, along with essential products like Everyday Welding Supplies, Miller 350p Manual, and Best 110v Mig Welder, are transforming the manufacturing industry. By achieving unprecedented levels of efficiency, precision, and sustainability, they are poised to shape the future of manufacturing for years to come.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R620 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

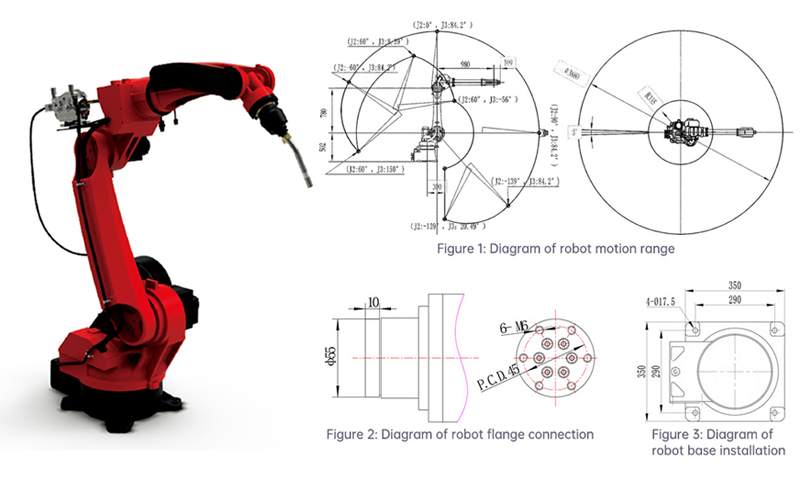

DIMENSIONAL DRAWINGS:

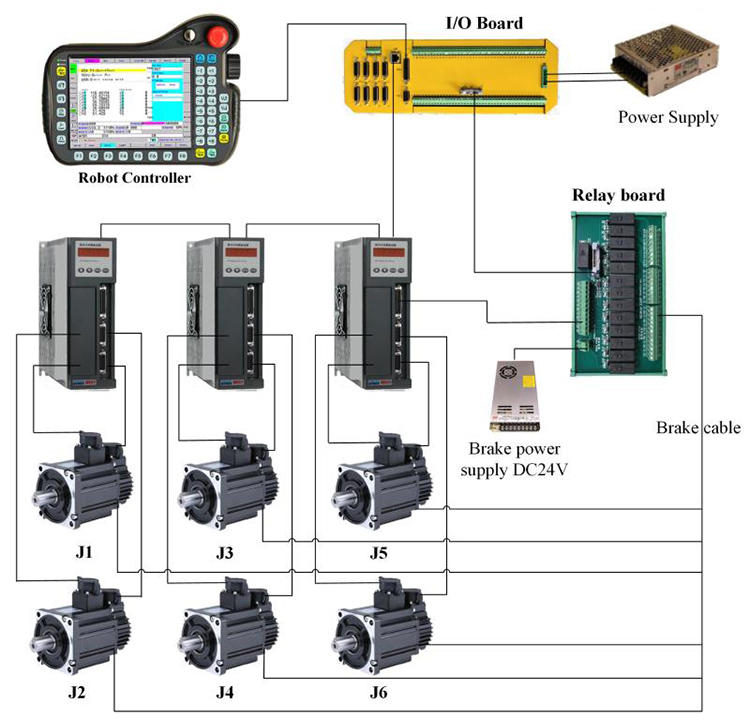

ROBOT CONTROLSYSTEM:

ADVANTAGE:

1,Free Saving

May be operated 24 hours, effec-tively hold difficult paintings expenses. in additionthe use of organisation manipulator operation mode, automated meeting line to keep the internet page, sothat the entire plant making plans more compact.

2,Immoderate Manufacturing Widespread General Normal Overall Performance

Manipulator manufacturing of a producttime is normal inside the identical production cycle, the output is ordinary product yield is excessive, immoderate manufacturing advantages.

3,Excessive Stability

Production operation, immoderate precision,excessive balance,can assure man or woman-nel,in choice to guide unstable operations.

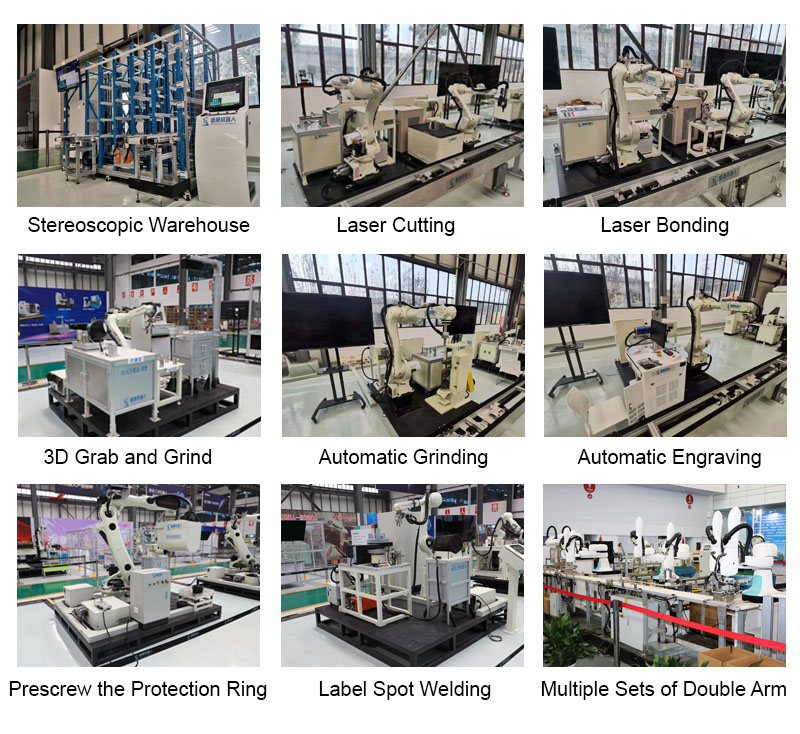

APPLICATIONS:

1, Production line, and car factors manufacturing. The pocket e-book vicinity calls for coordination a number of the positioner and welding robotic to gain automatic welding, with seamless movement that meets the welding song, speed, and gun function necessities.

2, The welding robotic production reduces manpower prices and improves everyday overall performance thru connecting workpiece conveying strains to form a manufacturing line.

3, Automobile factors production considerably benefits from welding robots, specifically inside the automobile chassis welding tool, wherein welding robot changed earlier operations, enhancing each welding notable and operation time.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: