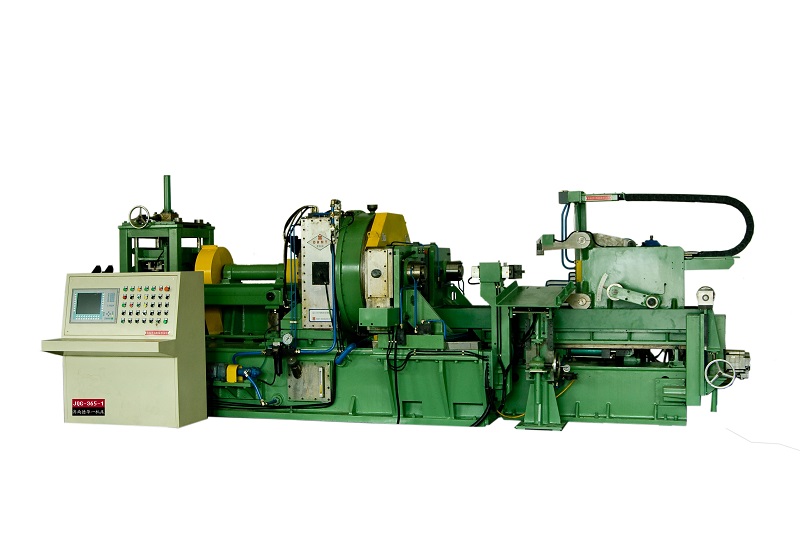

Tool Rotary Pipe Cutting Machine

Main Advantage Features:

1. Tool Rotary cutting and pipe fixed Patent technology

2. Green environmental protection, good energy saving, tool rotary cutting saves a lot of energy consumption due to the rotation of the steel pipe, greatly reducing carbon emissions.

2. High cutting efficiency, low operating cost, and multi-tool machining at the same time cutting mode, greatly improve cutting efficiency.

3. High processing precision, low cutting noise, greatly reducing the noise pollution generated by the processing process

4. Ethernet-based motion control platform, with a high degree of automation, can fully realize the automation of steel pipe processing

Tool Rotary Pipe Cutting Machine

JQG series Tool Rotary CNC pipe cutting machine is a patent pipe cutting machine developed by our company. It adopts the principle of gear differential feed, the tube body is not moving, the tool is rotating at high speed, and the new concept of longitudinal feed cutting.

It effectively solves the problems of high energy consumption, machine jitter, low cutting efficiency, short tool life, and poor section quality, and can not be measured in the high-speed rotating processing of steel pipe.

The equipment adopts a Siemens control system, which can realize the automatic production of the whole process of feeding, sizing, cutting, marking, blanking, and waste discharge. Greatly improve the production efficiency of the factory.

This machine is especially suitable for high-efficiency precision machining of petroleum casing, welded pipe, high-pressure boiler pipe, pipeline pipe, and line pipe, which is widely used in petroleum, metallurgy, and other industries

The Cutting Machine Specification

| No | Item | Unit | JQG-230 | JQG-365 | JQG-460 | JQG-720 |

| 1 | Cutting Pipe Dia | mm | 76-230 | 139-365 | 177-460 | 323-720 |

| 2 | Pipe wall thickness | mm | 30 | 45 | 60 | 60 |

| 3 | Pipe Length | mm | 6000mm -15000mm | |||

| 4 | Spindle Speed | rpm | 600 | 400 | 320 | 150 |

| 5 | Feeding Travel | mm | 40 | 50 | 75 | 100 |

| 6 | Main Motor Power | Kw | 30 | 37 | 45 | 55 |

| 7 | Cutting Accuracy | mm | 0.05 | 0.05 | 0.05 | 0.05 |

| 8 | Cutting Verticality | mm | 0.015/100 | 0.015/100 | 0.015/100 | 0.015/100 |

| 9 | Roughness | um | Ra6.3 | Ra6.3 | Ra6.3 | Ra6。3 |

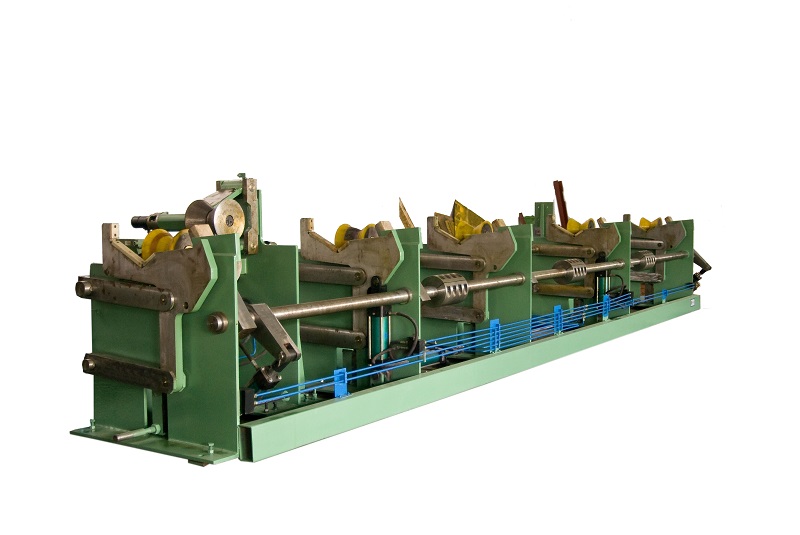

Commissioning On Site