Machine Loading and Unloading in Robotics: Enhancing Efficiency and Productivity

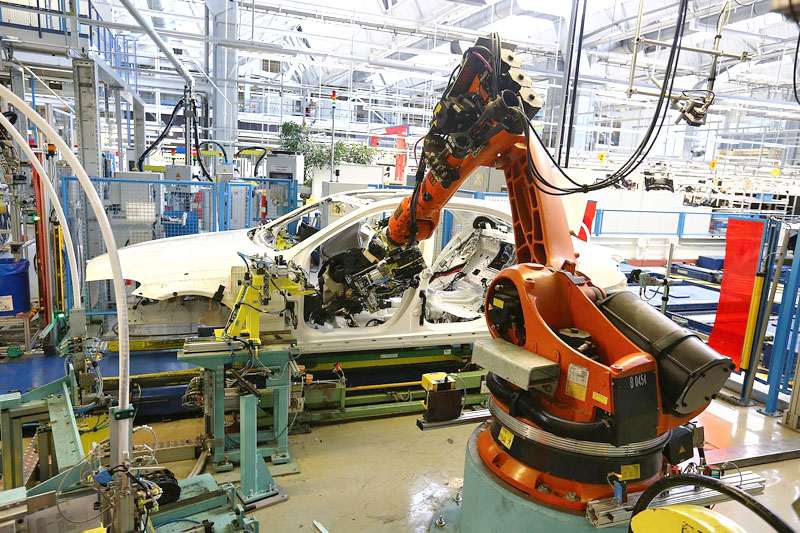

Machine loading and unloading is a critical process in industrial robotics. With the advancements in technology, high-tech intelligent robots have been developed to perform these tasks efficiently and effectively.

Industrial robotics, as taught in the NPTEL course, plays a significant role in automating various industrial processes. One such process is machine loading and unloading. Traditionally, this task was performed by human workers, which could be time-consuming, physically demanding, and prone to errors. However, with the introduction of high-tech intelligent robots, this process has been revolutionized.

These robots are equipped with advanced sensors and programming capabilities, allowing them to identify and handle different materials accurately. They can efficiently load raw materials into machines and unload finished products, ensuring a smooth and continuous production flow. Moreover, these robots can be programmed to perform these tasks repetitively, reducing the need for human intervention and increasing productivity.

One of the key advantages of using high-tech intelligent robots for machine loading and unloading is their ability to work in hazardous environments. Some industrial processes involve working with toxic chemicals, extreme temperatures, or heavy machinery. By deploying robots in such environments, the risk to human workers can be minimized, ensuring their safety and well-being.

Furthermore, these robots can be programmed to adapt to different machine types and sizes, making them versatile and flexible. They can easily handle various materials, including metals, plastics, and composites, with precision and accuracy. This adaptability allows manufacturers to streamline their production processes, reduce downtime, and improve overall efficiency.

In conclusion, machine loading and unloading in robotics has been transformed by the introduction of high-tech intelligent robots. These robots offer numerous benefits, including increased productivity, improved safety, and adaptability to different materials and environments. As technology continues to advance, we can expect further enhancements in this field, making industrial processes more efficient and effective.