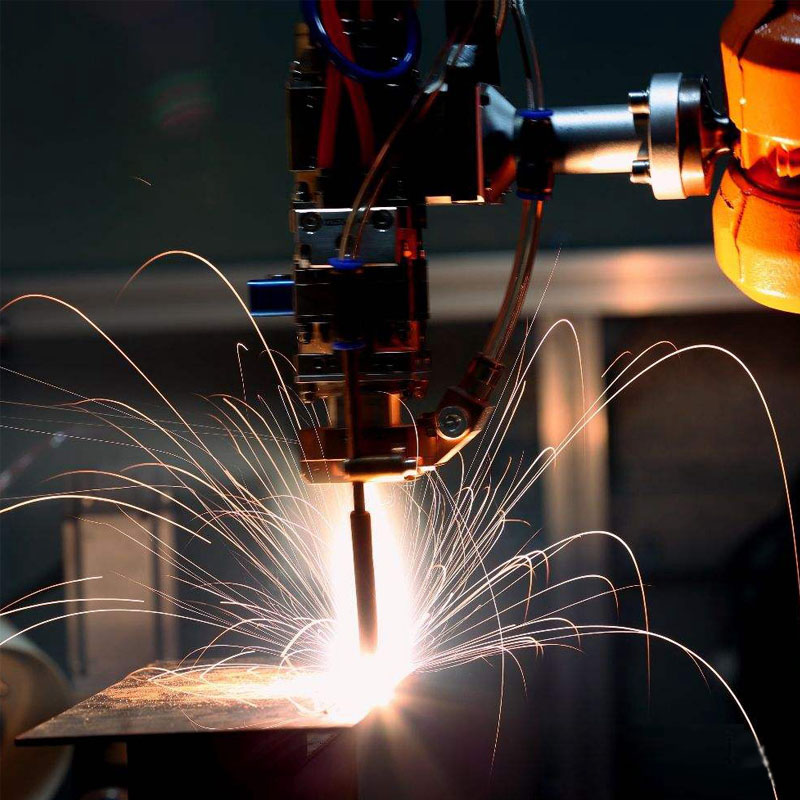

What Is a Robotic Welding Machine?

In the manufacturing industry, robotic welding has become increasingly popular due to its many benefits. With the use of robotic welding machines and systems, the welding process has become more efficient and cost-effective. These tools use precise control over welding parameters and automation to ensure consistency and high-quality welding.

Robotic welding systems are designed to facilitate uniform and high-quality welding by eliminating the factors that lead to human errors, making them ideal for large-scale and high-volume production. Universal robots welding takes precision to the next level with specialized sensors and vision systems that provide greater accuracy and optimal performance.

While the initial cost of robotic welder equipment can be high, the long-term savings on labor costs and increased productivity make the investment worthwhile. For manufacturers, robotic welding machines and systems offer significant efficiency gains in the production process, leading to higher productivity and lower operating costs.

Robotic welding also enhances worker safety by eliminating the risk of exposure to hazardous materials and extreme temperatures.

The integration of robotic welding technology in the manufacturing process provides many benefits to businesses, including increased efficiency, improved productivity, and a higher quality of work. This technology can significantly boost a company's competitive edge in the market.

In summary, the use of robotic welding machines, robotic welding systems, universal robots welding, and other robotic welding technology has led to a significant transformation of the manufacturing industry, delivering greater efficiency, cost savings, and safer working conditions.

Related Products

Submitted successfully

We will contact you as soon as possible