How Does Laser Cutting Work?

Glowforge Laser Cutter,Robot in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters, is a revolutionary device that has transformed the world of laser cutting. It provides precision, speed, and ease of use in cutting and engraving materials like wood, acrylic, leather, and more.

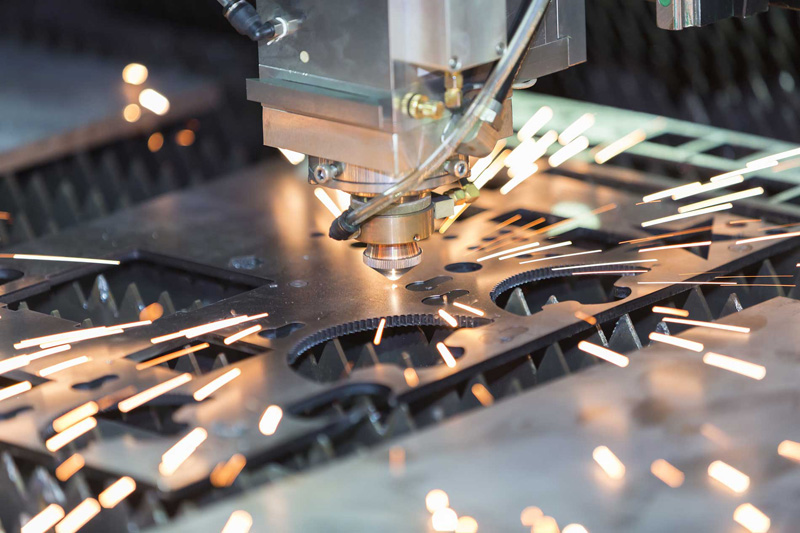

Stainless steel laser cutting is one of the applications of the Glowforge Laser Cutter. Stainless steel is a tough and durable material that poses a significant challenge to traditional cutting methods. With the aid of the Glowforge Laser Cutter, Mep Design Engineers can now achieve precision cuts and greater productivity when working with anti-corrosive materials like stainless steel.

Mep Design Engineers have the advantage of using laser cutting in a myriad of ways. From creating intricate designs in metals and plastics to making precise cuts in wood for furniture and decorative pieces, laser cutting has become an indispensable tool for design engineers.

Laser cutting has several advantages over traditional cutting methods. It is faster, more precise, and more efficient. With the aid of computer-aided design software, designers can create intricate designs that the Glowforge Laser Cutter can reproduce with high precision.

In summary, the Glowforge Laser Cutter has revolutionized the field of laser cutting. Its advanced technology and ease of use have made it a go-to device for Mep Design Engineers, helping them achieve greater productivity and precision when working with various materials like stainless steel. Laser cutting has opened up new possibilities in design, allowing for greater creativity and precision in the creation of various objects.