HT-T320A Laser Tube Cutting Machine

The HT-T320A is specifically designed for precision tube cutting, pipe cutting, profile cutting, and H Steel cutting. The machine boasts the following key features.

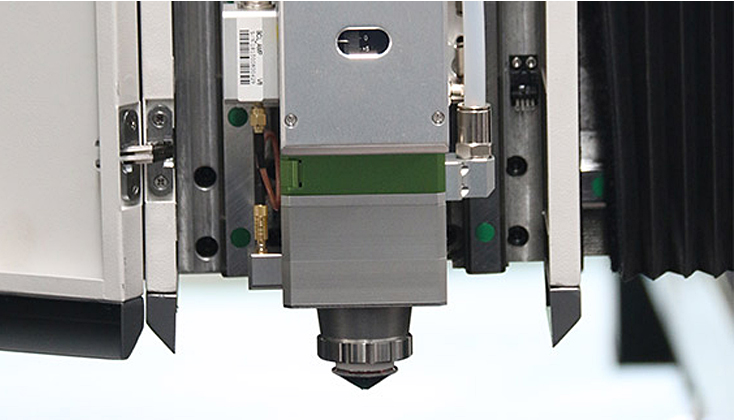

1. Raytools Laser Cutting Cutting Head

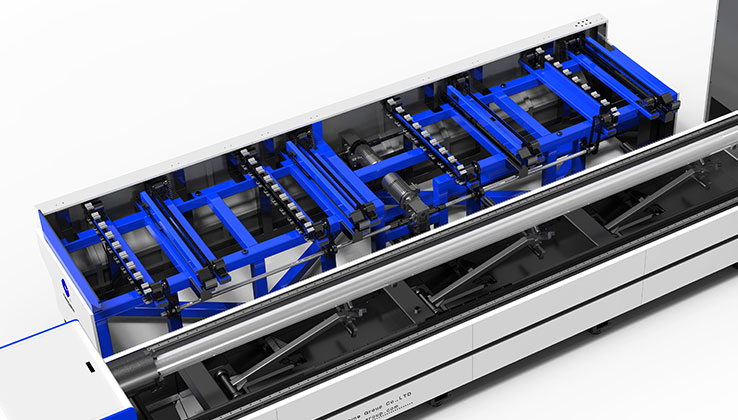

2. Rack Transmission, Pneumatic Chucks

3. Fron Feeding System Saves the materials collecting time

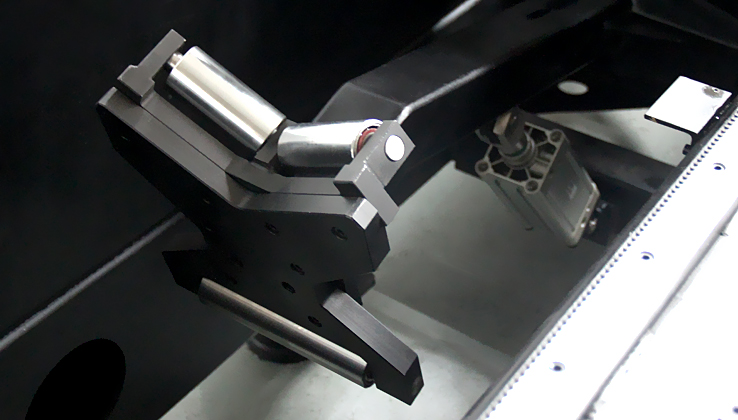

4. Servo Follower Support highlights the cutting accuracy

HT-T320A Laser Cutting Machine

Professional tube fiber laser cutting machine adopts bus control, fast and efficient, and also adopts rack transmission,

and follow-up roller, ensuring higher cutting accuracy. It can cut square pipes, round pipes, waist round pipes, oval pipes,

and some special-shaped pipes, widely used in sports equipment, various types of pipes, water pipes, oil pipelines, and

other industries.

It uses the gear transmission chuck to hold the design and can adjust the center automatically, the operation is also

effortless

Processing diameter up to 320mm, suitable for larger pipes. The cutting precision of the product is up to 0.01mmwhich can greatly improve the work efficiency.

HT-T320A Laser Tube Cutting Machine Specification

| Model | HT-T320 A |

| Cutting Length | 6000mm, 9000mm , 12000 mm |

| Cutting Dia | 20-320 mm |

| Laser Power | 1000w-4000w |

HT-T320A Laser Cutting Machine Advantage

Rack Transformation and Pneumatic Chucks

it uses the gear transmission chuck to hold the design and can adjust the center automatically, the operation is also very simple. The machining diameter is between 20-320mm.

The cutting precision of the product is up to 0.01mm, which can greatly improve the work efficiency

Front Feeding Device

It makes the operation more convenient and saves the material collecting time.

Add small wheels at the bottom, convenient to take and place the pipe, and move to another side.

Raytools Laser Cutting Head

Laser head professional transmission system (linear guide rail, ball screw, sensor head), laser focus adjustment, combined with servo motor drive mechanism, through the automatic sensor to sense the distance of the surface of the metal being cut, and transmit the data to the drive controller; And the data is transmitted to the drive controller: the distance between the follow-up laser head and the cut surface can be kept constant automatically avoiding the cutting accuracy due to the unevenness of the metal surface, and avoiding damage the nozzle and other parts

Servo Follower Supporting Device

The unique supporting device keeps contact with the pipe surface when the pipe is fed and rotated. The supporting force is set according to the pipe specification to ensure effective support, prevent the pipe from sagging, reduce the axis swing when the pipe rotates, and improve the machining accuracy.