HT-T220A Tube Laser Cutting Machine

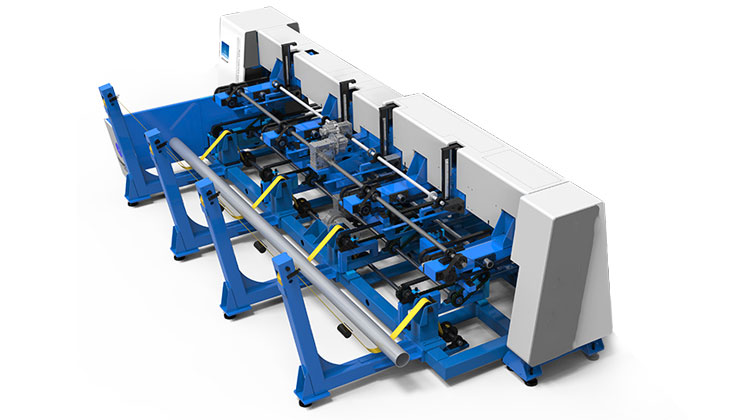

HT-T220A is a product targeted at the pipe-cutting market, featuring automatic feeding, automatic parting, follow-up support, automatic centering, follow-up unloading, Pressure real-time detection and other functions, using full stroke double action pneumatic chuck, bus control system, intelligent, efficient and stable, the product can meet the round pipe, square pipe, rectangular pipe, oval pipe and other kinds of pipe profile cutting, can be used in construction, food, decoration, advertising, sporting goods and other industries, Wide application range, high degree of automation, good cutting effect

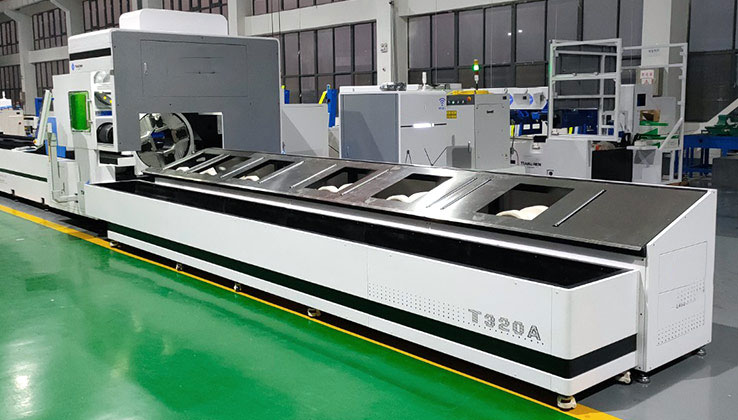

HT-T220A Laser Tube Cutting Machine

The Tube Cutting Machine adopts bus control, is fast and efficient, and also adopts rack transmission, a follow-up roller, and makes sure of higher cutting accuracy. It can cut square pipes, round pipes, waist round pipes, oval pipes, and some special-shaped pipes, cutting precision up to 0.01mm, and is widely used in sports equipment, various types of pipes, water pipes, oil pipelines, and other industries. It comes with an auto-feeding system, which is labor-saving, highly efficient, and more secure.

The Laser Tube Cutting Machine Specification

| Model | HT-T22A |

| Working Area | 6000mm , 9000 mm , 12000mm |

| Laser Power | 1000w-4000w |

| Effective Cutting Dia | 20-220 mm |

Laser Tube Cutting Machine Feeding System

The automatic feeding and unloading device comprises an Auto-feeding device and an unloading feeding device. T220A automatic feeding device is controlled by the CNC control system, which is seamlessly connected with the pipe-cutting machine to realize uninterrupted production. Automatic feeding of the whole bundle of pipes, the intelligent layout of pipes by the control system, and automatic conveying process.

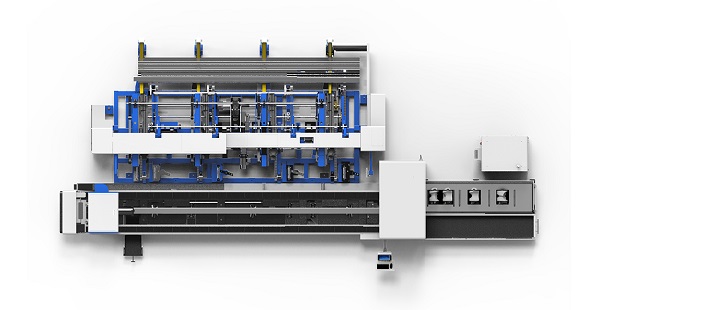

Servo Follower Supporting Device

The unique supporting device keeps contact with the pipe surface when the pipe is fed and rotated. The supporting force is set according to the pipe specification to ensure effective support, prevent the pipe from sagging, reduce the axis swing when the pipe rotates, and improve the machining accuracy.

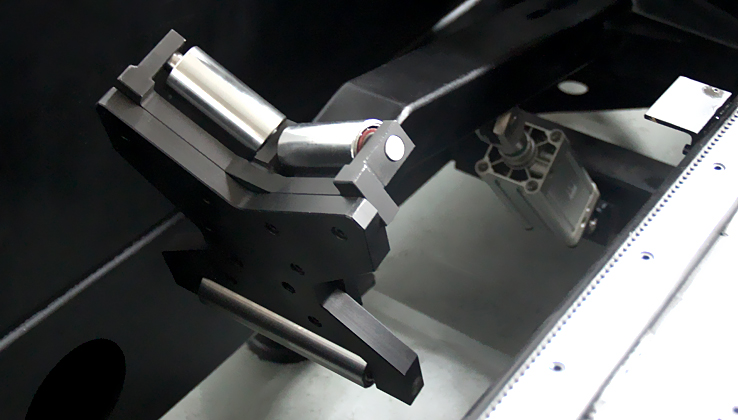

Rack Transmission and Pneumatic Chucks

It uses the gear transmission chuck to hold the design and can adjust the center automatically, the operation is also very simple. The machining diameter is between 20-200mm. The cutting precision of the product is up to 0.01mm, which can greatly improve the work efficiency

Fron Feeding Device

It uses the gear transmission chuck to hold the design and can adjust the center automatically, the operation is also very simple. The machining diameter is between 20-200mm. The cutting precision of the product is up to 0.01mm, which can greatly improve the work efficiency