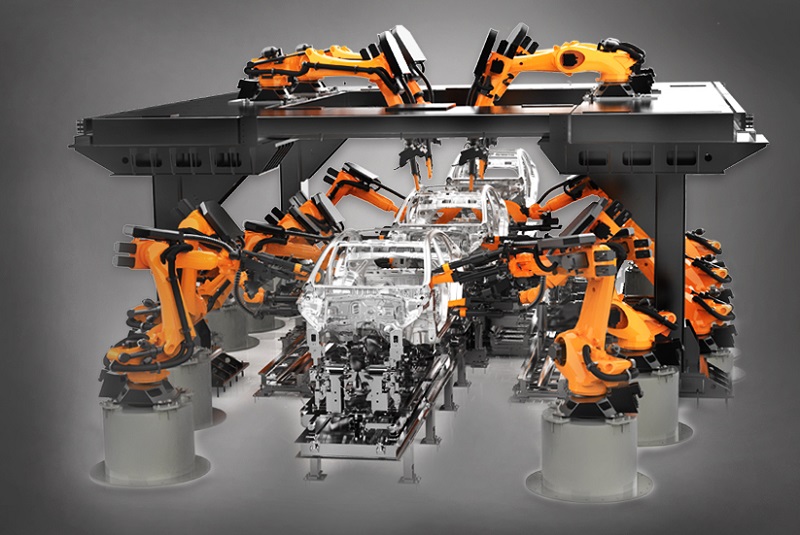

Automatic BIW Production Solution

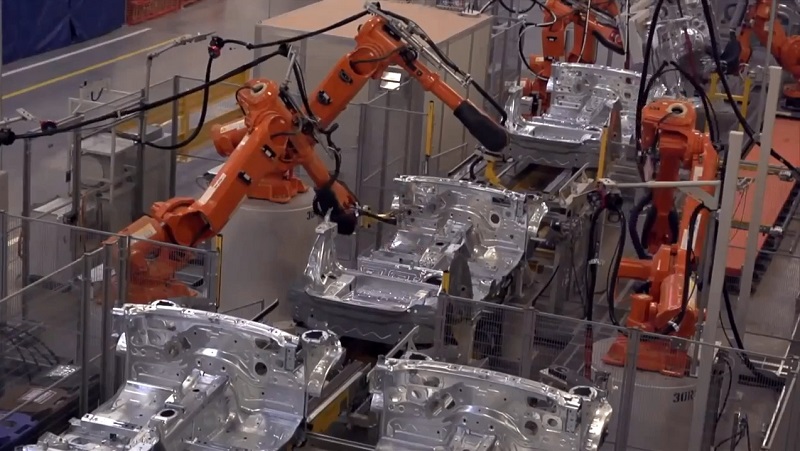

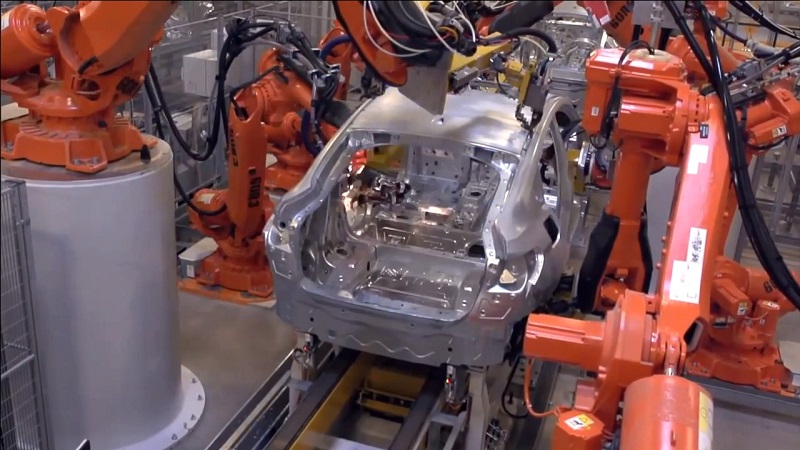

In the assembly process, we use various joining technologies, including folding, clinching, hemming, riveting, gluing, spot welding, MIG welding, brazing, laser cutting, and laser welding. Closure parts are usually screwed or welded.

We also increasingly use camera systems (vision systems) to position or handle parts. These vision systems are connected to robots and transmit the necessary process information, thus enabling the robot to determine its further processes.

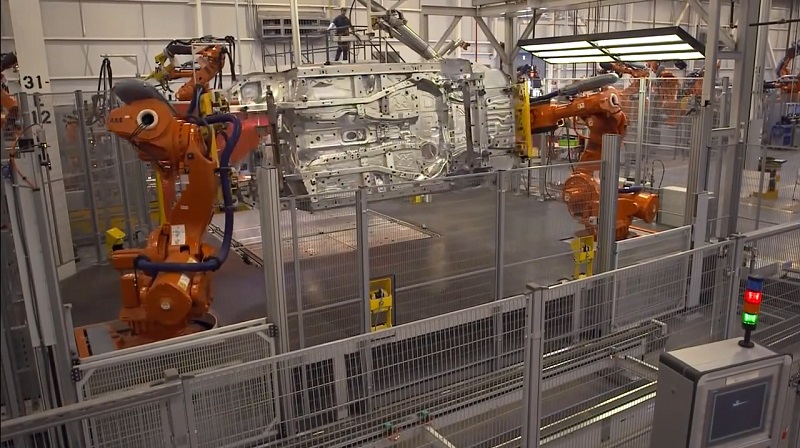

The products are transported almost fully automatically; the same goes for the application of joining techniques.

In addition to building completely new lines, we are also highly experienced in integrating new models into existing production facilities.

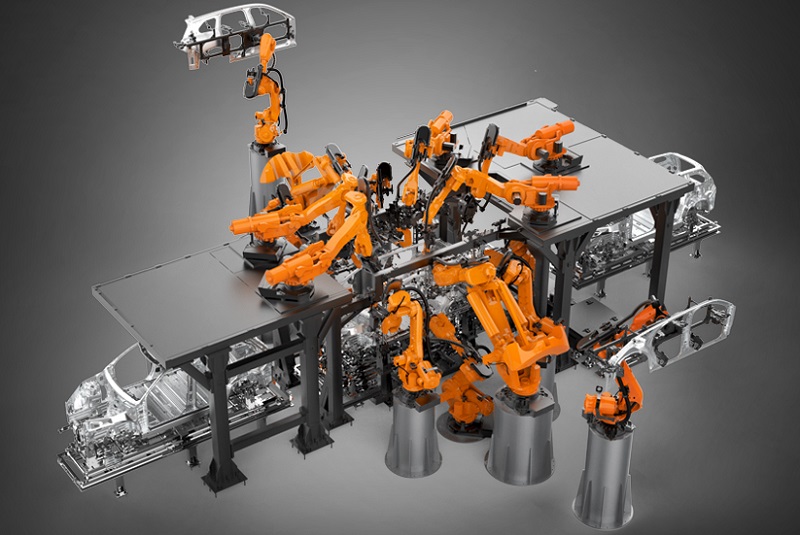

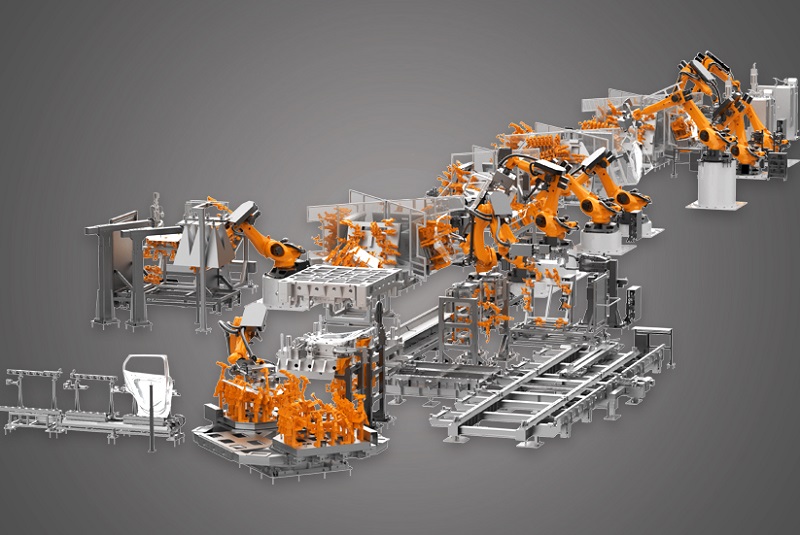

The engineering processes are characterized by a high level of digitalization up to building and commissioning complete factories in a digital world.

Automatic BIW Production Solution

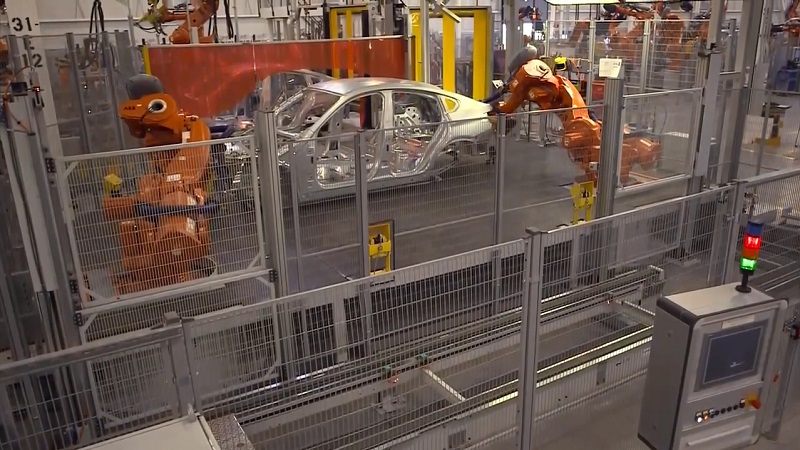

We develop and supply turnkey Production Systems for assembling body parts. The processes and production equipment

are fully tailored to our customers' wishes and requirements.

These projects tend to be highly automated production lines on which a mixture of different models can generally

be produced.

The lines are designed to produce several hundred to over 2,000 cars a day. we also deliver manual and semi-automatic

production lines for assembling lower volumes.

Automatic Welding Line

Robotic Automatic Welding System for BIW Parts

The Details BIW Production Line we offer

1. Closures Automatic Production Solution

It achieves automatic production by utilizing key processes such as robot hemming, welding, arc welding,

handling, and sealing.

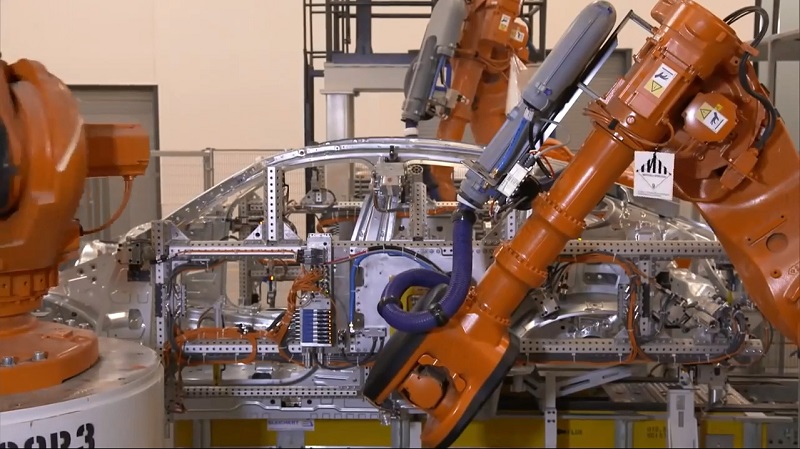

2. Body Side Automatic Production Solution

To achieve multiple models random build with turntable and fixture library changeover.To achieve full

automation production of welding, sealing, and handling with robots, APC, etc.

3. Body Side Automatic Production Solution

To achieve multiple models random build with turntable and fixture library changeover.To achieve full

automation production of welding, sealing, and handling with robots, APC, etc.

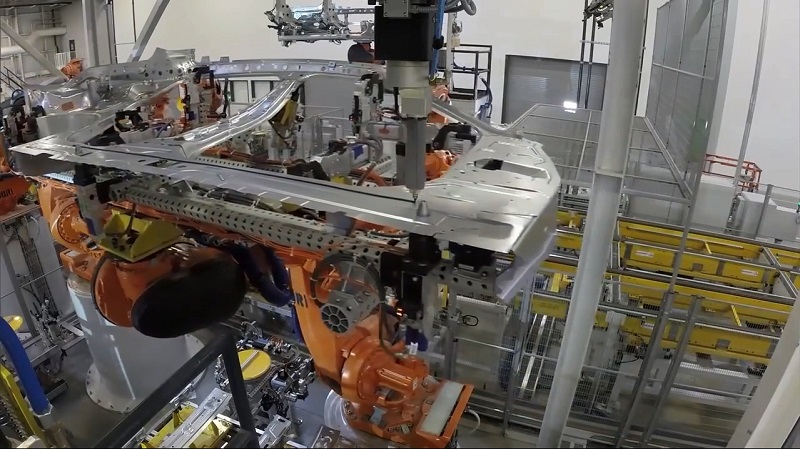

4. Framing Automatic Production Solution

BIW high-speed and high-precision transfer via high-speed roller bed and flex pallet.Multi-model random

production via framing technology.