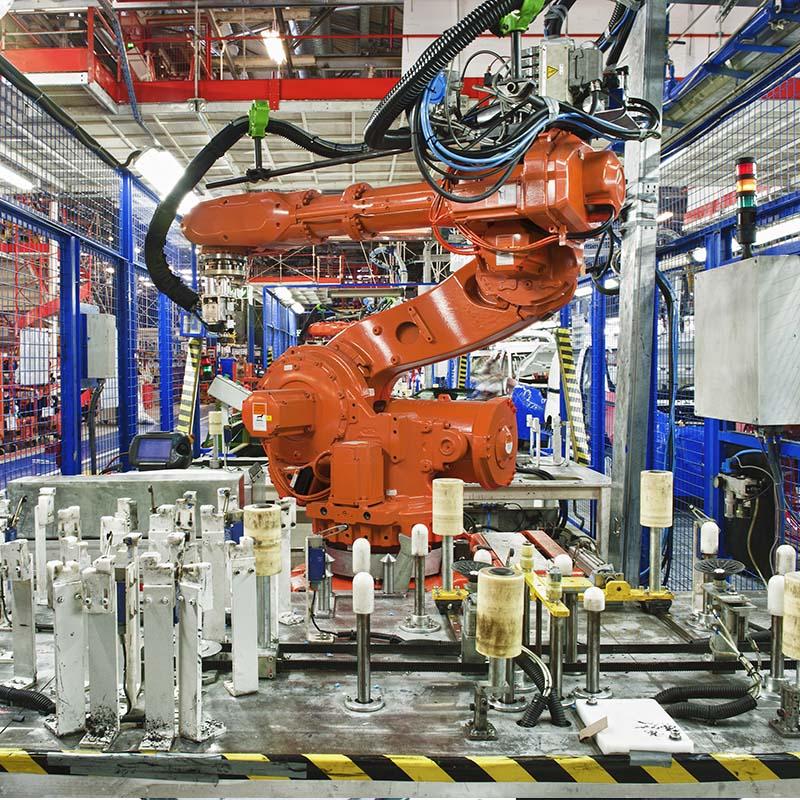

Robotic Welding Machine Manufacturers:Robotic welding machine manufacturers are constantly pushing the boundaries of technology to create more efficient and precise welding processes. These machines are equipped with robotic arms that can perform complex movements and weld with incredible accuracy.In addition to welding, robotic arms are also used in packaging applications. They can pick up products and place them in boxes or containers with speed and precision.

Contact Now

Cartesian Robot ManufacturersCartesian Robot Manufacturers, Industrial Robots and Cobots, Irobot Industry, and Robots in the Medical Industry are all important sectors in the field of robotics. These industries play a crucial role in enhancing efficiency, productivity, and accuracy in various sectors. From manufacturing processes to medical procedures, robots have revolutionized the way tasks are performed. With continuous advancements in technology, the future of robotics looks promising, with even more innovative and intelligent robots expected to enter the market.

Contact Now

Packaging Robot Manufacturers Solution:Robot Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.In the packaging industry, there are numerous leading manufacturers of packaging robots. They offer cutting-edge technology and innovative solutions for businesses. One such manufacturer is known for their automatic robot packing machines. These machines are designed to streamline the packaging process, offering enhanced efficiency and accuracy. One specific application is the packaging of battery packs for robots.

Contact Now

Panasonic Welding Robot ProgrammingPanasonic Welding Robot Programming offers a user-friendly interface, advanced features, and seamless integration to enhance the programming process. Panasonic Welding Robot Teaching allows for easy and intuitive setup of welding tasks, increasing productivity. When it comes to Robotic Welding Machine manufacturers, Panasonic is a renowned name known for its reliable and efficient solutions. Additionally, Yaskawa Mig Welding Robot offers precise and efficient welding capabilities, ensuring high-quality welds.

Contact Now

Autonomous Mobile Robot ManufacturersAutonomous Mobile Robot Manufacturers, such as Kuka and ABB Robotics Webshop, offer a range of advanced robotic arms for various industries. Kuka Small Robot Arm is known for its compact size and versatility, making it perfect for smaller workspaces. These robots are widely used in the electronics industry for tasks such as pick-and-place operations. With their precise movements and high-speed capabilities, they increase efficiency and productivity.

Contact Now

Chinese Industrial Robot Manufacturers:Chinese Industrial Robot Manufacturers are key players in the global robotics industry, leveraging their robust manufacturing infrastructure, technological advancements, and market understanding. They provide cost-effective and customized solutions for various industries.Cartesian Robot Arduino is a popular choice among hobbyists and small-scale automation projects.

Contact Now

Spot Welding Robot System:Spot Welding Robot System is a cutting-edge technology that is revolutionizing the manufacturing industry. Kuka Rsi Control, one of the top robotic companies, has developed this system to enhance productivity and efficiency. The system utilizes the Ur5 Robot Arm, which is known for its precision and versatility. With this advanced technology, manufacturers can automate the spot welding process, reducing human error and increasing production speed.

Contact Now

Robot Car Body Welding:Robot car body welding has revolutionized the automotive industry. It offers numerous advantages in terms of efficiency, precision, and safety. Manufacturers like Kuka Group Input have embraced this technology, leveraging the speed and productivity of robots to increase production rates. These robots perform welding tasks with immense precision, ensuring consistent and high-quality welds on car bodies. The use of robots also promotes safety by eliminating the need for human operators to handle hazardous welding tasks.

Contact Now

Robotic Equipment Manufacturers:Robotic Equipment Manufacturers such as Kawasaki Industrial Robots, Kuka Kr 200, and Mir Agv Robot provide exceptional solutions for automation needs. Kawasaki Industrial Robots are known for their high performance and reliability, offering a wide range of robot models to suit various applications. The Kuka Kr 200, with its strong payload capacity, provides efficient handling and precise movements. Mir Agv Robot specializes in autonomous mobile robots, enabling flexible material transportation in industrial settings.

Contact Now

For welding products, you can use a collaborative robot to automate a welding application quickly and easily.By connecting a welding torch to the robot and then having it move along the desired path, accurately laid welds are created. The cobot always moves at the desired speed and is accurate to within 0.1mm. In this way the cobot ensures consistent, high quality end products. Compared to a standard robot cell, the cobot offers a number of advantages.

Contact Now

Welding robot manufacturers worldwide are producing welding robots that are becoming increasingly popular in industries that require precision, speed, and safety in welding operations. There are various types of welding robots available on the market, including articulated robots, cartesian robots, and SCARA robots. These welding robots are manufactured using advanced techniques and technologies to meet specific customer requirements. The most commonly used type of welding robot is the robotic welding arm, which offers the flexibility and versatility needed in welding applications.

Contact Now

Abb Welding Robots Company:Abb Welding Robots Company and Kuka Welding Robot are two well-known manufacturers of 6-axis robots. These robots have revolutionized the welding industry with their precision and efficiency.Abb Welding Robots Company has been a leader in the robotics industry for many years. Their welding robots are known for their high-quality construction and advanced technology. These robots are capable of performing complex welding tasks with ease, making them a popular choice among manufacturers.Kuka Welding Robot is another prominent player in the market.

Contact Now

Autonomous Mobile Robot Manufacturers:In today's era, the integration of automation and robotics in construction has led to the rise of autonomous mobile robot manufacturers. These companies produce state-of-the-art robots that revolutionize various construction processes. From material transportation to site surveying, autonomous mobile robots offer unprecedented efficiency, accuracy, and safety. Additionally, the construction industry witnesses the emergence of top industrial robotics companies as key players in this realm.

Contact Now

Robot Car Body Spot Welding:Robot Car Body Spot Welding has become increasingly popular in the automotive industry. Manufacturers like Kuka Roboter GmbH have developed advanced 6 Degree of Freedom (6 DOF) Robotic Arms for this purpose. These robotic arms are programmed using Arduino code to perform precise spot welds on car bodies.To ensure seamless operations, companies like ABB Robot offer excellent tech support to troubleshoot any issues that may arise during the welding process.

Contact Now

The system includes positioning tooling, feeding robot, servo positioning system, welding robot, safety protection system, and other components. The loading robot picks up the workpiece to be welded, and the servo positioning system can detect the angle and distance of the workpiece base, and the loading robot puts the workpiece to be welded in the clamping state to the welding station, and the welding robot automatically completes the welding.

Contact Now

The system realizes automatic assembly of parts, automatic spot welding, automatic full welding, and other actions by integrating a six-axis handling robot, six-axis welding robot, 3D camera, 2D camera, and displacement machine to achieve fully automatic assembly and welding of parts.DSHJ-10RSWeldable materials: carbon steel, alloy steel, stainless steel, aluminum, copper, titanium and their alloysThe system realizes automatic assembly of parts, automatic spot welding, automatic full welding, and other actions by integrating a six-axis handling robot, six-axis welding robot, 3D camera, 2D came

Contact Now

It can realize automatic scanning code storage and complete paperless office: the automatic wire welding robot system uses the 3D vision system to accurately calculate the welding area and check the number of wires. The label printer can print the required information on the label according to the information sent by the MES system. The robot grabs the welding stud and the label, and completes the label welding according to the coordinate information sent by the 3D camera.DSHB-NL21Suitable bundle diameter: φ150 ~ φ350mm;Wire diameter: ≥ 8 mm;Identification range: ≥ 350mm × 500mm.

Contact Now

Tig Welding RobotTig Welding Robot, Robotic Laser Welding, Daihen Welding Machine, and Robotic Welding in the Automotive Industry are all advanced technologies that have revolutionized welding processes.Tig Welding Robot is a robotic system that uses Tungsten Inert Gas (TIG) welding technique. It offers high precision and accuracy, making it ideal for welding applications in the automotive industry. This robot can perform complex welds with ease, ensuring consistent quality and reducing human error.Robotic Laser Welding is another cutting-edge technology used in the automotive industry.

Contact Now

Otc Daihen Welding RobotThe Otc Daihen Welding Robot, Panasonic Mig Welding Robot, Panasonic Robotic And Welding Equipment, and Panasonic Robotic Welding Machine are all top-notch solutions for welding applications. The Otc Daihen Welding Robot excels in its advanced technology, high-speed performance, excellent welding quality, versatility, user-friendly interface, reliability, and durability. The Panasonic Mig Welding Robot offers precise and efficient welding capabilities, ensuring consistent and high-quality welds.

Contact Now

Robot Welding a Car:In the manufacturing industry, robot welding has emerged as a game-changing technology. When it comes to assembling cars, Robot Welding a Car offers numerous advantages. It enhances precision by ensuring consistent and accurate welds, resulting in stronger connections between car parts. The use of robots also increases efficiency, as they can work continuously without breaks or fatigue, reducing cycle times and boosting overall productivity. Moreover, robot welding promotes safety in the workplace by eliminating the need for human operators to perform hazardous tasks.

Contact Now