Structural Design Engineer Aerospace:The field of aerospace design requires skilled professionals who understand the nuances of structural design. That's why having a Structural Design Engineer Aerospace is essential for businesses looking to take on projects in this field. They can help ensure that designs are optimized for safety and efficiency.But having a good design is only half the battle. Welding is also an important part of aerospace manufacturing. Finding Welding Shops Near Me that specialize in aerospace welding can be critical in producing high-quality final products.

Contact Now

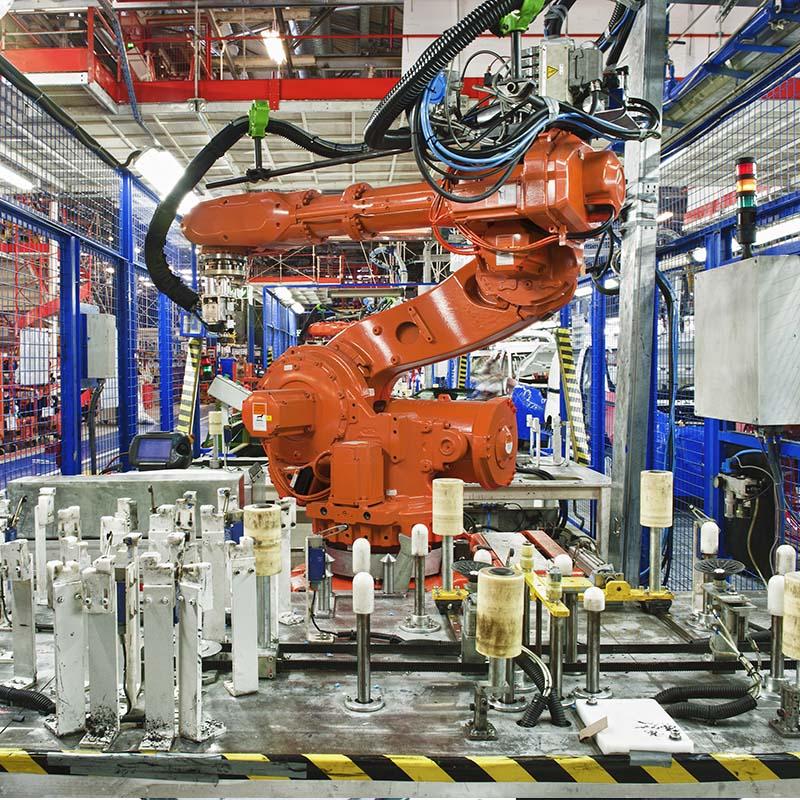

KUKA Servo Robot:KUKA Servo Robots are revolutionizing small welding services near me. With their precision and versatility, they are the perfect fit for various welding needs. Coupled with a top-notch Thermal Arc Tig Welder, these robots produce high-quality welds consistently. And if you're looking for affordable options, Hobart Welders for sale provide reliable and cost-effective solutions. These welding machines and robots work seamlessly together, ensuring efficient and accurate results.

Contact Now

Kuka Kr c2The Kuka Kr c2, along with the availability of robotics electronics shops near me, facilitates the accessibility and utilization of advanced robotic systems. The Kr c2’s advanced control capabilities and ease of programming make it a reliable choice in industrial automation. Moreover, the convenience of nearby robotics electronics shops ensures easy access to spare parts and technical support. Meanwhile, the Kuka Kr 120 r3200 Pa offers high payload capacity, expanding the range of applications for heavy-duty industries.

Contact Now

Automated welding systems, along with the use of underwater welding robots, are revolutionizing the welding industry. Automatic welding has significantly increased productivity while also improving the quality of the weld. The use of an auto feed TIG welder further increases this efficiency as it allows for continuous welding without the need for stopping and starting. This automation not only saves time and money but also reduces the risk of human error and injury.

Contact Now

The portable welding workstation parameterized the skills and practical experience of senior welders, copied and migrated to the software side, and created a "0" threshold automation tool that can also be used by general workers. It greatly reduced the difficulty of welding technology, cracked the pain points of the welding industry, and made joint efforts in ease of use, versatility and safety, greatly expanded the application scenario of welding automation, and innovated the welding production mode.

Contact Now

Types Of Manufacturing Robots:Nowadays, manufacturing robots have become a popular choice for many manufacturing companies to improve production efficiency. Common types of manufacturing robots include Everlast Welders Tig robots and Stainless Steel Welding Wire robots. These robots can perform repetitive tasks during the manufacturing process to improve productivity and greatly reduce human errors, thus improving product quality. Furthermore, robots can operate at a higher level of precision, making more complex and sophisticated parts and assemblies.

Contact Now

Welding Car Manufacturing Robots Solution:Welding Car Manufacturing Robots, such as those produced by Kuka, have revolutionized the automotive industry. Welding Car Manufacturing Robots Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.These robots offer numerous advantages, including increased efficiency, enhanced accuracy, and improved safety. With continuous work capabilities, they boost productivity and reduce production time, surpassing human welders.

Contact Now

Machine Loading And Unloading Robots:Machine Loading And Unloading Robots are efficient and reliable tools for the automation of industrial processes. These robots are designed to handle heavy machinery and equipment, reducing the risks associated with manual labor.Another affordable option for industrial automation is the Cheap Industrial Robot Arm. This cost-effective solution provides a range of capabilities including picking, placing, and assembly tasks.

Contact Now

Robotic Process Automation (RPA) Systems:Robotic Process Automation (RPA) Systems have emerged as a game-changer in industrial automation solutions. With the ability to automate repetitive tasks, these systems optimize productivity and efficiency in various industries. Industrial automation integrators play a crucial role in implementing RPA systems, ensuring seamless integration with existing infrastructure. They possess the expertise to customize and calibrate these systems, taking into account specific requirements and industry standards.

Contact Now

Robots Technology In Steel Industry:Robots Technology in the Steel Industry has witnessed significant advancements in recent years. The introduction of new robots technology has greatly increased efficiency and productivity in this sector. The advantages of robotics technology cannot be overstated.With the implementation of robots technology, steel manufacturers have experienced a remarkable improvement in their operational efficiency. These robots can perform repetitive tasks with precision and speed, resulting in increased output.

Contact Now

Mir Amr Robots Solution:Mir Amr Robots Solution is a cutting-edge technology that specializes in machinery automation and robotics. It offers innovative solutions for various industries, including manufacturing and production. One of its remarkable products is the Lesta Painting Robot, which revolutionizes the painting process in industrial settings.The Lesta Painting Robot is designed with advanced features that enhance efficiency and precision. It uses state-of-the-art technology to automate the painting process, eliminating the need for manual labor.

Contact Now

Robotic Textile Manufacturing:Robotic Textile Manufacturing, the use of automation and robotics in the textile industry, has revolutionized the production processes. With the introduction of Hrp 5p Humanoid Construction Robot, the industry has witnessed increased efficiency and accuracy in construction tasks. According to the World Robotics 2020 Industrial Robots report, the global market for industrial robots continues to grow, with a particular focus on the manufacturing sector.

Contact Now

Smart Advanced Construction Robotics Solutions:Smart Advanced Construction Robotics Solutions, driven by automation technology for machines, are revolutionizing the construction industry. With their precision and efficiency, these solutions optimize construction processes and ensure high-quality results. Similarly, pharma automation technology plays a vital role in the pharmaceutical industry by automating various processes, including manufacturing, packaging, and quality control.

Contact Now

Robotics For Foundry Solution:The future of robotics in the foundry industry looks promising. With advancements in technology, robots can perform tasks with higher precision and speed, increasing productivity and reducing errors. They can also work in hazardous environments, improving safety standards. The integration of AI and machine learning can further enhance their capabilities, enabling predictive maintenance and real-time decision making. Furthermore, the adoption of robotics can lead to significant cost savings in the long run.

Contact Now

Steel Surface Machining Robots:The latest robot technology, such as Steel Surface Machining Robots, equipped with a Linear Motorized Arm and Programmable Robotic Arm, has revolutionized various industries. These advanced robots deliver exceptional precision, speed, and flexibility in manufacturing processes. The Steel Surface Machining Robots offer increased productivity, precision, and safety in surface machining tasks. With their linear motorized arm capabilities and programmable features, these robots can execute complex motions and perform intricate tasks with unparalleled accuracy.

Contact Now

Robot In Sewer Pipe:In the world of robotics, there are various fascinating machines that serve different purposes. One such example is the Robot In Sewer Pipe, designed specifically for navigating through narrow sewer pipes to perform inspections and maintenance tasks. Another remarkable robot is the Robot Kuka Kr20, known for its precision and versatility in industrial applications. If you're looking for a robotic arm, the Jaco Arm is a popular choice, offering advanced functionality and a wide range of motion.

Contact Now

Robot In Petroleum:The integration of robots in the petroleum industry has revolutionized operations, enhancing efficiency and safety. Kuka ROS Industrial is a leading provider of robotic solutions, offering cutting-edge technology for various applications. When considering robotic arm prices, it's essential to evaluate the specific requirements and functionalities needed. SCARA robot arms, known for their speed and precision, are a popular choice in many industries.

Contact Now

s7 AutomationThe S7 Automation is a cutting-edge technology that revolutionizes the manufacturing process. With its advanced features and capabilities, it enhances productivity and efficiency in industries. The Kuka Kr 210 r2700 2 is a powerful robot that is widely used in the manufacturing sector. Its high precision and flexibility make it an ideal choice for various applications. Another notable robot in the industry is the Hiwin Scara Robot, known for its speed and accuracy.

Contact Now

Advanced Cylindrical Robot Automation:Electrical and automation technologies have revolutionized the manufacturing industry, enabling supply chain automation companies to provide efficient and streamlined factory automation solutions. One such advanced solution is the implementation of cylindrical robot automation. These robots offer increased productivity, enhanced safety, and flexibility in manufacturing processes. With the integration of electrical and automation technologies, supply chain automation companies can optimize production workflows and maximize efficiency.

Contact Now

New Robot Technology 2022:Introducing New Robot Technology 2022: Kuka KR 210, Asteroid Mining Robot, and Robots for Injection Molding2022 brings exciting advancements in the field of robotics. The Kuka KR 210 emerges as a game-changer, offering enhanced precision and versatility in industrial applications. In the realm of space exploration, the Asteroid Mining Robot showcases its ability to extract valuable resources from celestial bodies. Additionally, robots tailored for injection molding processes revolutionize the manufacturing industry, optimizing production efficiency.

Contact Now

Silicon Valley Robotics Companies:Silicon Valley Robotics Companies are known for their technological prowess and innovative solutions. One popular robot offered by these companies is the UR5 Robot, which provides flexibility and precision in automation tasks. While the UR5 Robot price may vary, it is seen as an investment due to its versatility and collaborative capabilities.Another widely used robotic solution is the cylindrical robot arm.

Contact Now