Unimate Robot Integration:Unimate Robot Integration, powered by Industrial Automatics Technology, has revolutionized industrial processes. PLC Automation Engineers from B and R Industrial Automation play a pivotal role in this integration. These skilled professionals program and maintain the programmable logic controllers (PLCs) that control the Unimate Robots. The result is increased productivity, improved quality control, and enhanced workplace safety. Unimate Robots tirelessly perform tasks, boosting efficiency and output. Their precision ensures consistent and superior product quality.

Contact Now

Robot Unimate 1954:Robot Unimate 1954 is considered a groundbreaking invention in the field of factory automation robots. This robot technology revolutionized the manufacturing industry by introducing automated processes that increased efficiency and productivity.The use of automation robotics technology, such as the Unimate 1954, has significantly transformed the way factories operate. These robots are capable of performing repetitive tasks with precision and speed, reducing the need for human intervention.

Contact Now

The Unimate - A Revolutionary Robot:The Unimate, a revolutionary robot, has paved the way for automation robotics, transforming industries globally. With its innovative capabilities, it has revolutionized manufacturing processes, increasing productivity and efficiency. Alongside other robotics and automation companies, the Unimate has played a crucial role in driving advancements in the field. Nidec Automation, in particular, has emerged as a key player in Industry 4.0.

Contact Now

The Unimate SolutionThe Unimate Solution, Assembly Robot Solution, Robot Comau Solution, and Universal Robots Ur5 are all innovative robotic solutions that have revolutionized various industries.The Unimate Solution was the first industrial robot ever created, introduced in 1961. It paved the way for automation in manufacturing processes, increasing productivity and efficiency.Assembly Robot Solution is designed specifically for assembly line tasks.

Contact Now

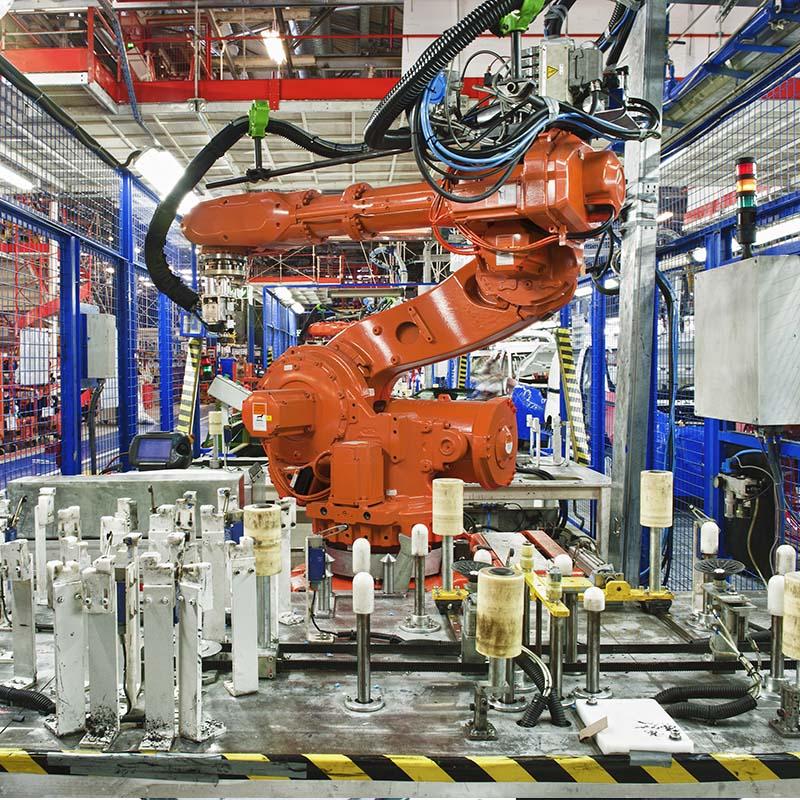

Abb Robotics And Discrete AutomationABB Robotics and Discrete Automation is a leading provider of automation solutions. With their expertise, Exyn Tech offers innovative autonomous drone systems for various industries. Unimate 001, the world's first industrial robot, revolutionized manufacturing. Automation & Robotics Engineering specializes in integrating robotics into existing systems.

Contact Now

Unimate Robot Automation Assembly:Unimate Robot Automation Assembly, Stick Shielded Metal Arc Welding, ASME Section 9 Brazing Procedures, and Victor Welding Cutting Torches are all important tools and processes used in modern manufacturing and fabrication. The Unimate Robot Automation Assembly is a versatile tool that can help streamline the manufacturing process, resulting in higher efficiency and better product quality.

Contact Now

Robotics And Automation EngineeringRobotics and automation engineering has revolutionized the manufacturing industry. One of the pioneers in this field is Unimate Robot Solution, which was developed by Joseph Engelberger. Unimate was the first industrial robot, capable of performing repetitive tasks with precision and speed.The success of Unimate led to the widespread adoption of articulated robot solutions. These robots have multiple joints, allowing them to move in a more human-like manner.

Contact Now

Robotic Mining Equipment:Robotic Mining Equipment, Industrial Robot Motor, ABB IRB6400RM2000, and Unimate First Industrial Robot are all innovative technologies that have revolutionized the mining and industrial sectors.Robotic Mining Equipment offers numerous advantages in the mining industry. These robots can navigate through hazardous and dangerous environments, reducing the risk to human workers.

Contact Now

New Robotics Technology 2021:New Robotics Technology 2021: Articulated Robot Arm, Cartesian Robot Arm, Unimate First RobotIn the ever-evolving field of robotics, exciting advancements continue to emerge in 2021. Three notable developments are the articulated robot arm, Cartesian robot arm, and the Unimate – the first robot.The articulated robot arm is a cutting-edge technology that replicates the movements of a human arm. With multiple joints and segments, it offers enhanced flexibility and dexterity in performing various tasks.

Contact Now

Diy Industrial Robot:DIY Industrial Robot, Unimate Industrial Robot, Miso Robotics Fast Food, and ABB, Kuka, Fanuc, Yaskawa are all notable names in the field of industrial robotics. These companies have revolutionized various industries with their advanced technologies and innovative solutions. DIY Industrial Robot provides individuals with the opportunity to build their own robots, fostering creativity and learning. Unimate Industrial Robot was the first robot used in an industrial setting, paving the way for automation in manufacturing.

Contact Now

Robotics In Renewable Energy:Robotics in renewable energy has transformed the industry. The use of robots, starting with the Unimate Robot in 1961, has optimized various processes. Industrial robot manipulators have improved the efficiency and accuracy of tasks such as solar panel installation and wind turbine maintenance. Additionally, the integration of Mir Autonomous Mobile Robots has allowed for autonomous inspection and monitoring of renewable energy systems, reducing human intervention and increasing productivity.

Contact Now

Carbon Block Cleaning System:Robotics and automation engineering has revolutionized the way that we work and manufacture products. Industrial robot applications have played a significant role in the success of many companies, enhancing productivity and consistency in manufacturing processes. One of the most important developments in industrial robots was the creation of the Unimate Robot by George Devol in 1956. This robot was the first industrial robot ever produced, and it paved the way for modern automation techniques and revolutionized the industry.

Contact Now

Nachi Scara RobotNachi Scara Robot excels in precision assembly, enhancing efficiency in manufacturing. Robotics and Automation play a pivotal role, streamlining processes and ensuring consistent quality. ROS Industrial Fanuc integrates seamlessly, optimizing control and coordination. Unimate 2000 pioneered industrial robotics, laying the foundation for the automated future. Together, these technologies revolutionize manufacturing, offering speed, accuracy, and reliability for the ever-evolving industry.

Contact Now

Carbon Block Task Allocation Robots:The use of robotics technology continues to evolve in many industries across the globe. One of the most innovative developments in this field is the use of Carbon Block Task Allocation Robots in carbon block production. These robots are equipped with high-precision sensors and advanced programming, ensuring accurate measurement and positioning of carbon blocks, and ultimately improving the quality of the end product.The Carbon Block Task Allocation Robots are an evolution of the Unimate Robot Arm, which was the first-ever industrial robot.

Contact Now

Automation And Robotics TechnologyAutomation and Robotics Technology, embodied by the Kawasaki Unimate, has significantly impacted various industries. These technologies have proven advantageous in terms of reducing labor costs, improving efficiency, and ensuring safety in manufacturing processes. While the initial investment in industrial robots may be substantial, the long-term benefits outweigh the costs, including heightened productivity and enhanced quality control.

Contact Now

Robots Used In Automobile Industry:Robots have become an integral part of the automobile industry, revolutionizing production processes. One popular controller used in automotive robotics is the Kuka KRC4 Controller, known for its precision and reliability. Additionally, the emergence of 3D printing technology has allowed for the creation of innovative robot arms that are cost-effective and customizable. The Unimate Robot Arm, introduced in the 1960s, was one of the first industrial robots used in car manufacturing.

Contact Now

Robotics And Automation Engineering:Three-dimensional fiber laser cutting machine,which belongs to the Robotics And Automation Engineering, such as unimate robot, articulated robot,manufacturing robots,is composed of special fiber laser cutting head, high precision capacitive tracking system,fiber laser and industrial robot system, to different thickness of metal plate multi-angle, multi-azimuth flexible cutting equipment.

Contact Now

Affordable Robotics And AutomationAffordable Robotics and Automation, along with Automated Process Control Systems, have revolutionized industries across the globe. The introduction of Unimate 1900 and Mitsubishi 6 Axis Robot has further propelled this transformation. These advanced robotics and automation solutions have made manufacturing processes more efficient, accurate, and cost-effective. With their ability to perform repetitive tasks with precision, these robots have significantly reduced human intervention, leading to increased productivity and reduced labor costs.

Contact Now

Iai Scara Robot:The IAI SCARA Robot is a remarkable example of the advancements in robotic technology. With its precise movements and high-speed capabilities, it has become an invaluable asset in various industries. It follows in the footsteps of the first robot, Unimate, which revolutionized manufacturing processes. However, the IAI SCARA Robot takes automation a step further by being able to collaborate with human workers, ensuring safety and efficiency. Companies like Mayura Automation & Robotic Systems are leveraging this technology to optimize production workflows.

Contact Now

Robotics And Automation Engineering:As technology continues to evolve, robotics and automation engineering have made significant advances in Industry Robot, labeling robot, and automatic label spot welding robot. This has led to many benefits, including increased efficiency and productivity. By utilizing an industry robot control system, these robots can operate with minimal downtime, streamlining the work process. Furthermore, safety has improved through the development of robots like Unimate robot applications, which can perform hazardous tasks and preserve worker safety.

Contact Now

Tig Welding Robot PriceTig Welding Robot Price, Automated Tig Welding, Cobot Tig Welding, Robotic Tig Welder For SaleTig welding is a popular method used in various industries for its precision and high-quality results. With the advancement of technology, automated tig welding has become a game-changer in the welding industry. These automated systems, such as tig welding robots and cobots, offer increased productivity and efficiency.When it comes to purchasing a tig welding robot, the price can vary depending on various factors.

Contact Now

Tig Welding RobotTig Welding Robot, Robotic Laser Welding, Daihen Welding Machine, and Robotic Welding in the Automotive Industry are all advanced technologies that have revolutionized welding processes.Tig Welding Robot is a robotic system that uses Tungsten Inert Gas (TIG) welding technique. It offers high precision and accuracy, making it ideal for welding applications in the automotive industry. This robot can perform complex welds with ease, ensuring consistent quality and reducing human error.Robotic Laser Welding is another cutting-edge technology used in the automotive industry.

Contact Now

Cobot Lincoln ElectricCobot Lincoln Electric, Panasonic Welding Robot, and other robotic welding companies like ABB offer advanced solutions for welding processes. These robots provide high precision and efficiency in welding tasks, ensuring superior quality and productivity. The price of ABB welding robots varies depending on the model and specifications, ranging from a few thousand to several hundred thousand dollars. With their innovative features and capabilities, these robots are revolutionizing the welding industry, making it easier and faster to achieve accurate and flawless welds.

Contact Now

Yaskawa Welding Robot PriceYaskawa Welding Robot Price refers to the cost of Yaskawa's welding robots. These robots are designed to perform automated welding tasks, increasing productivity and efficiency in industrial settings. Yaskawa's welding robots are known for their reliability, accuracy, and advanced features. However, the exact price of these robots may vary depending on specific models and additional customization requirements.Yaskawa Cobot Welding combines Yaskawa's collaborative robots, also known as cobots, with welding capabilities.

Contact Now