Robots Used In FactoriesRobots are widely used in factories for manufacturing automation. Kuka HQ is a renowned company specializing in robotics and manufacturing automation. One of their notable creations is the substation inspection robot. This robot is designed to inspect substations, ensuring their proper functioning and safety. With the advancement of robotics technology, factories are becoming more efficient and safer.

Contact Now

Robots Used In Transportation:Robots Used In Transportation, Robotics In Warehouse Material Handling, Robotic Parts Suppliers, and Painting Robot For Sale are significant developments in the field of automation. Robots used in transportation offer increased efficiency, safety, and cost-saving benefits. They can work without rest, minimizing human error and optimizing logistics. Robotics in warehouse material handling bring enhanced productivity and accuracy, streamlining operations and reducing labor costs.

Contact Now

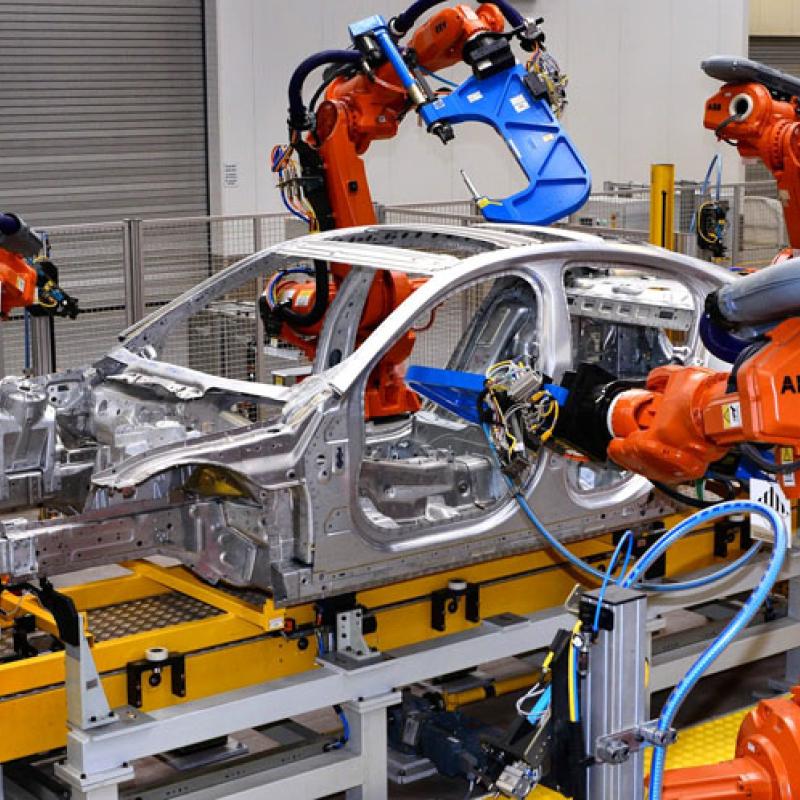

Robots Used In Automobile Industry:Robots have become an integral part of the automobile industry, revolutionizing production processes. One popular controller used in automotive robotics is the Kuka KRC4 Controller, known for its precision and reliability. Additionally, the emergence of 3D printing technology has allowed for the creation of innovative robot arms that are cost-effective and customizable. The Unimate Robot Arm, introduced in the 1960s, was one of the first industrial robots used in car manufacturing.

Contact Now

Robotics Used In Manufacturing Industry:The use of robotics in the manufacturing industry has greatly revolutionized production processes, with one notable application being the assembly of robot arms, specifically the articulated or jointed arm robot.Robot arm assembly plays a crucial role in the manufacturing of robots themselves. The articulated robot arm, with its flexible jointed design, mimics the movement capabilities of a human arm.

Contact Now

Robots Used In Steel Industry:Robots used in the steel industry, specifically in steel mills and steel fabrication, bring several advantages. These robots enhance productivity through their ability to work at a faster pace and reduce production cycle times. They also improve safety by performing hazardous tasks such as handling molten metal or operating heavy machinery. Additionally, robots in steel mills can work in high-temperature environments, reducing the exposure of human workers to extreme heat.

Contact Now

Robots In Industry Manufacturing:Robots in Industry Manufacturing, also known as robotic arms, have transformed the manufacturing industry in numerous ways. These advanced machines offer several advantages that have revolutionized production processes.Firstly, robots used in manufacturing industry significantly enhance productivity and efficiency. With their ability to work continuously without fatigue or errors, these robots can perform tasks at a much faster rate than human workers.

Contact Now

Robotics In Garment Manufacturing:Robotics has been increasingly used in various industries as technology advances, with garment manufacturing, Alstom inspection, and medical engineering being some of the sectors that have seen the most advances.Robotics in garment manufacturing is used to automate the production of garments. By using robots, the industry can produce garments with greater accuracy and speed than manual labor.

Contact Now

Industries That Use Robots In Manufacturing:Industries that use robots in manufacturing, such as Tesla Robots Manufacturing, are experiencing significant advantages. Collaborative industrial robots, also known as cobots, are playing a crucial role in this transformation. These robots work alongside human workers, enhancing productivity and efficiency while ensuring a safe working environment. Tesla Robots Manufacturing, for example, utilizes industrial cobots to automate various assembly tasks, resulting in faster production cycles and improved quality control.

Contact Now

Industrial Robots In Manufacturing:Industrial Robots in Manufacturing have revolutionized the production process. One such innovation is the Robotic Arm with its multiple degrees of freedom. The Jaco Robotic Arm, for instance, offers six degrees of freedom, allowing it to move in various directions and perform complex tasks. This technology has significantly improved efficiency and productivity in the manufacturing industry.Furthermore, industrial robots have paved the way for Robotic Process Automation (RPA) technology.

Contact Now

Advantage Of Using Robot In Industries:The advantages of using robots in manufacturing industries are increased productivity, improved product quality, and reduced labor costs. Robots excel at repetitive tasks and can work consistently without getting tired. They can also handle dangerous or hazardous tasks, ensuring the safety of human workers. DIY industrial robot kits provide an opportunity to learn and explore robotics, improving skills and knowledge.

Contact Now

Automobile Manufacturing Robots:Automobile Manufacturing Robots, such as the Kuka PRC Robots in Architecture, have gained widespread attention due to their numerous advantages. One key aspect is the degree of freedom in robotics, which enables these robots to perform complex tasks with precision. Additionally, these robots contribute to environmental sustainability, as seen in the rising trend of Green Energy Robotics. They are designed to be energy-efficient, reducing energy consumption and carbon emissions.

Contact Now

Types Of Manufacturing Robots:Nowadays, manufacturing robots have become a popular choice for many manufacturing companies to improve production efficiency. Common types of manufacturing robots include Everlast Welders Tig robots and Stainless Steel Welding Wire robots. These robots can perform repetitive tasks during the manufacturing process to improve productivity and greatly reduce human errors, thus improving product quality. Furthermore, robots can operate at a higher level of precision, making more complex and sophisticated parts and assemblies.

Contact Now

Robot Technology In Car Manufacturing Solution:Robot technology has played a crucial role in revolutionizing car manufacturing. China, being one of the largest automobile manufacturers, is at the forefront of utilizing robots in their car factories. These robots are used in various aspects of the manufacturing process, from assembling car parts to quality control. By incorporating robots in car factories, production efficiency has significantly increased, allowing for shorter lead times and cost savings.

Contact Now

Robotic Welding In ManufacturingRobotic welding is widely used in manufacturing for its efficiency and precision. It is commonly used in industries such as automotive, aerospace, and electronics. Robotic welding systems can perform repetitive welding tasks with high accuracy and speed, resulting in improved productivity and reduced labor costs. These systems are capable of welding various materials, including steel, aluminum, and stainless steel. They can also handle complex welding patterns and produce consistent weld quality.

Contact Now

Companies That Use Robots In Manufacturing:Companies that use robots in manufacturing, such as ATI Robotics Solutions and Advanced Robotics Technology, are at the forefront of technological advancements in the industry. These companies understand the benefits of integrating robot arms into their production processes. Robot arms, like those provided by ATI Robotics Solutions, offer precision, speed, and efficiency, leading to increased productivity and reduced costs Advanced.

Contact Now

Manufacturing Robots Artificial IntelligenceLeveraging cutting-edge technology, the integration of Manufacturing Robots, Artificial Intelligence, Staubli Tx2 140, Mir500 Robot Solution, and Xy Cartesian Robot heralds a new era in industrial automation. The Staubli Tx2 140, equipped with advanced AI capabilities, epitomizes precision and adaptability on the production line. Complemented by the Mir500 Robot Solution, seamless mobility and collaborative functionality redefine efficiency in material handling.

Contact Now

Robots In Medical FieldRobots have revolutionized various industries, including the medical field. In recent years, robots have been increasingly used in surgeries and other medical procedures, providing more precise and efficient outcomes. Additionally, a wall painting robot has been developed, eliminating the need for manual labor in this tedious task. Moreover, the ABB robot arm has become a popular choice in industrial automation, offering high-speed and accurate movements. Lastly, mining robot solutions have been employed to enhance safety and productivity in mining operations.

Contact Now

Manufacturing Robots Solution:Manufacturing Robots Solution, including the Painting Robot Solution, Energy Robotics Solution, and Cylindrical Robot Solution, offers numerous advantages for various industries. These solutions automate repetitive tasks increasing productivity while reducing human error. The Painting Robot Solution ensures consistent and high-quality paint application. The Energy Robotics Solution optimizes energy consumption by employing robots in energy-intensive processes.

Contact Now

Robotics And Manufacturing:Robotics and manufacturing play a crucial role in modern industries. With the rise of automation, industrial robotics companies like Kuka Kr 150 have emerged as leaders in the field. Kuka Kr 150 offers high-performance industrial robots that are widely used in manufacturing processes.These robots are equipped with advanced technology and can perform a range of tasks with precision and efficiency.

Contact Now

Welding Car Manufacturing Robots Solution:Welding Car Manufacturing Robots, such as those produced by Kuka, have revolutionized the automotive industry. Welding Car Manufacturing Robots Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.These robots offer numerous advantages, including increased efficiency, enhanced accuracy, and improved safety. With continuous work capabilities, they boost productivity and reduce production time, surpassing human welders.

Contact Now

Manufacturing Robots For Sale:Manufacturing robots have become increasingly popular in industries worldwide. One of the largest industrial robotics companies is Kuka, known for its advanced technology and innovative solutions. Their Kuka KR 180 2 PA is a prime example of their cutting-edge products. This robot is known for its ability to handle heavy payloads and perform high-speed movements with great precision.Another type of robot gaining popularity is the collaborative Scara robot.

Contact Now

Manufacturing Industries Use Robot:In the world of manufacturing industries, the utilization of robots has become indispensable. Industrial Robotic Robots and Industrial Robotic Equipment are revolutionizing production processes. These highly advanced machines perform a wide range of tasks with precision and efficiency. Robots in Machine Shops have become a common sight, as they automate various operations, such as material handling, assembly, and packaging. The integration of robots in manufacturing industries offers several advantages.

Contact Now

Best Robot Manufacturing Company In The World:The best robot manufacturing company in the world is known for its exceptional technology and innovation. They offer a wide range of robots, including SCARA robots, at competitive prices. Their arm automation robotics machines are highly efficient and reliable, optimizing industrial processes. For those interested in pursuing a career in robotics and automation, a Master's degree in Robotics and Automation (M Tech) can provide the necessary knowledge and skills.

Contact Now

Robotics In Automobile Industry:Robotics in the automobile industry has revolutionized manufacturing processes. With the integration of advanced robotic systems, tasks in assembly lines have become more efficient and precise. Kuka Robot Price refers to the pricing of Kuka robots, which are widely used in the automotive sector for their reliability and versatility. These robots offer a range of models and configurations to suit different manufacturing needs.

Contact Now