Robotics In Foundry Solution:Robotics in foundry is characterized by automation, precision, and efficiency. Robotics In Foundry Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters. These robots are designed to handle high-temperature, high-risk tasks such as pouring molten metal, removing castings, and finishing operations. They are programmed to perform repetitive tasks with high accuracy, reducing human error and increasing productivity.

Contact Now

Robotics In Foundry Solution:Robotics in foundry applications has revolutionized the manufacturing industry. Robotics In Foundry Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.Robots are used for tasks such as casting, molding, and finishing, reducing human involvement and increasing efficiency and precision. They can withstand harsh conditions, including high temperatures and dust, ensuring consistent production quality.

Contact Now

Robotics For Foundry Solution:The future of robotics in the foundry industry looks promising. With advancements in technology, robots can perform tasks with higher precision and speed, increasing productivity and reducing errors. They can also work in hazardous environments, improving safety standards. The integration of AI and machine learning can further enhance their capabilities, enabling predictive maintenance and real-time decision making. Furthermore, the adoption of robotics can lead to significant cost savings in the long run.

Contact Now

Robot In Foundry Solution:Robot Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.Robots in a foundry are used to automate tasks such as pouring, casting, and finishing. To use them, first, program the robot with the specific task it needs to perform. This could be done using a software interface provided by the robot manufacturer. Then, position the robot in the correct place in the production line. Ensure safety measures are in place to protect human workers.

Contact Now

Robots For Foundry Solution:Robots for Foundry are revolutionizing the industry, making processes more efficient and safer. One company leading this change is DeSheng Robot Foundry. Their advanced robotic systems are designed to handle a variety of tasks, from molding and casting to finishing and inspection, reducing human error and increasing productivity. DeSheng Robot Foundry reviews from customers highlight the company's commitment to quality and innovation. Users praise the robots for their precision, reliability, and ease of use.

Contact Now

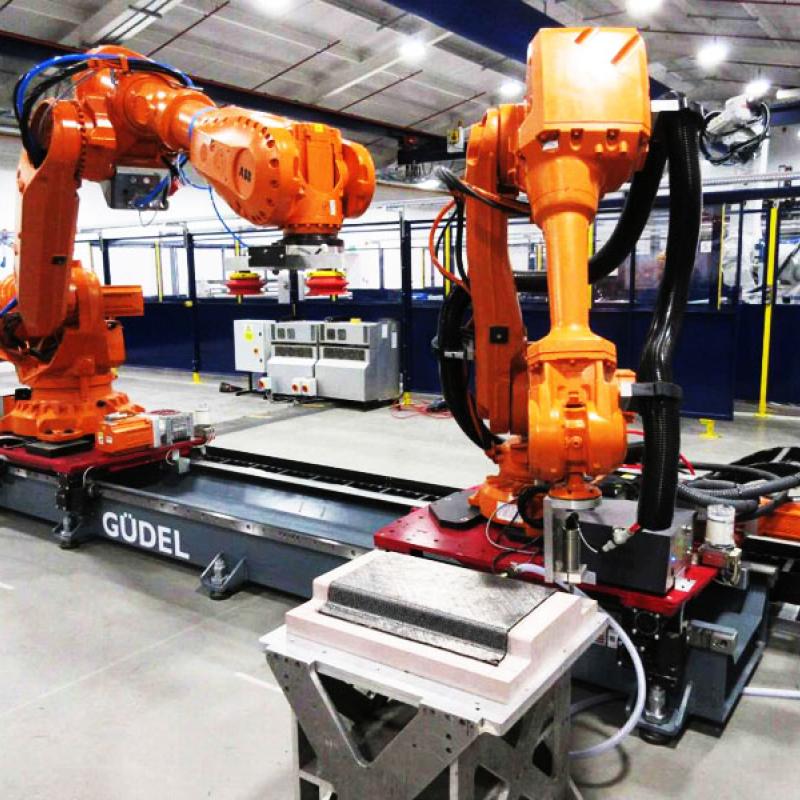

Abb Foundry Robots Solution:ABB Foundry Robots are revolutionizing the manufacturing industry with their advanced technology and high precision. These robots are specifically designed for harsh environments, making them perfect for tasks such as casting. The introduction of Casting Soft Robot, a more flexible and adaptable version, has further enhanced the efficiency and safety of the process. Foundry Plus Robot, another variant, offers additional features and benefits, tailored to meet the specific needs of a foundry.

Contact Now

Foundry Robotic Automation Solution:In the realm of industrial automation, Foundry Robotic Automation has revolutionized the casting process. These robots, such as the Tale Foundry Robot and the Kuka Foundry Robot, are designed to handle high temperatures and harsh environments, providing a safer and more efficient alternative to manual labor. They are capable of performing precise, repetitive tasks, such as pouring molten metal into molds, with consistent accuracy.

Contact Now

Abb Foundry Robot Solution:ABB Foundry Robots are primarily used in industries for tasks such as material handling, machine tending, casting, die casting, and spot welding. They are designed to withstand harsh and high-temperature environments. These robots increase productivity, improve quality, and enhance safety in the workplace. They are also used in the automotive industry for tasks such as assembly, painting, and welding. ABB Foundry Robots are also capable of performing more complex tasks, such as 3D printing, with precision and accuracy.

Contact Now

Robot In Manufaturing Industries Video:In the realm of manufacturing industries, the integration of robotics has revolutionized production processes. Videos highlighting the efficiency and effectiveness of robots in various manufacturing tasks have become popular. The Robot Foundry has emerged as a pioneer in providing advanced robotic solutions for industrial manufacturing. The concept of Robotics In Industry 5.0 focuses on collaborative robots and human-robot interaction, leading to increased flexibility and productivity.

Contact Now

Kuka Foundry RobotKuka Foundry Robot, Kuka Linear Robot, and Tx Scara Robot are three advanced robotic systems developed by The High Tech Robotic Systemz Ltd. These robots are equipped with cutting-edge technology and are designed to perform complex tasks with precision and efficiency. With their advanced features and capabilities, these robots are revolutionizing the manufacturing industry and enhancing productivity. The High Tech Robotic Systemz Ltd continues to innovate and develop state-of-the-art robotic solutions to meet the ever-evolving needs of industries worldwide.

Contact Now

Robotics In Packaging:Robotics in packaging is a rapidly growing technology that is changing the way goods are packaged and shipped. Fanuc LR Mate 200ID 7L is an advanced robot arm that is designed to automate and simplify packaging processes. It can be used to package items of various sizes and shapes, and can be programmed to perform multiple tasks, such as sorting, labeling, and sealing.

Contact Now

Automated Robotics In Logistics:Automated Robotics in Logistics and Robotic Assembly Solutions are two innovative technologies developed by Rockwell Automation Company. These solutions have revolutionized the logistics and manufacturing industries by streamlining processes and increasing efficiency. With the help of Human Machine Interface (HMI), operators can easily control and monitor these robotic systems, ensuring smooth operations.

Contact Now

Material Handling In RoboticsMaterial handling in robotics has become increasingly important in various industries. Companies like Kuka, known for their powerful and versatile Kuka KR 1000 Titan, are leading the way in providing innovative solutions. While the price of the Kuka KR 1000 Titan may be high, the benefits it offers in terms of efficiency and productivity justify the investment. Additionally, there are other reputable robotics companies worldwide that excel in material handling, such as ABB, Fanuc, and Yaskawa.

Contact Now

Robotics In Renewable Energy:Robotics in renewable energy has transformed the industry. The use of robots, starting with the Unimate Robot in 1961, has optimized various processes. Industrial robot manipulators have improved the efficiency and accuracy of tasks such as solar panel installation and wind turbine maintenance. Additionally, the integration of Mir Autonomous Mobile Robots has allowed for autonomous inspection and monitoring of renewable energy systems, reducing human intervention and increasing productivity.

Contact Now

Robotics In Indian Industry:Robotics in the Indian industry has gained significant momentum, with the country becoming a hub for robotics innovation and development. The presence of top robot manufacturers and technology companies has been instrumental in driving this growth. These companies, through their advanced robot technologies, have transformed industrial operations and processes. The FANUC Robot Er 4ia, for instance, offers superior performance and versatility, enabling efficient automation in various industries.

Contact Now

Robotics In Garment Manufacturing:Robotics has been increasingly used in various industries as technology advances, with garment manufacturing, Alstom inspection, and medical engineering being some of the sectors that have seen the most advances.Robotics in garment manufacturing is used to automate the production of garments. By using robots, the industry can produce garments with greater accuracy and speed than manual labor.

Contact Now

Automated Robotics In Logistics:Automated robotics in logistics have made a significant impact in streamlining operations and optimizing efficiency in the supply chain industry. With the development of sophisticated robots and specialized software, logistics companies can now automate repetitive tasks such as picking, packing, and sorting. This ensures faster processing times, fewer errors, and a reduction in labor costs.Auto assembly line robots are commonly used in the automotive manufacturing industry.

Contact Now

Mecademic 500Mecademic 500, ABB Foundry Robot, Cleaning Robot Technology, and Pick and Place Automation Equipment are innovative technologies that have revolutionized various industries. These advanced machines have enhanced productivity, efficiency, and accuracy in tasks such as assembly, cleaning, and material handling. With their precise movements and intelligent programming, they have become indispensable tools for businesses worldwide.

Contact Now

Robotics In Steel Industry:Robotics in the steel industry has seen significant growth in recent years. Robots are being extensively used in various processes, making the industry more efficient and productive. From welding and cutting to material handling, robots have proven their capabilities. Their precision and accuracy have resulted in higher quality products and reduced errors. Moreover, robots minimize the risk for workers by performing tasks in hazardous environments.

Contact Now

Robotics In Food IndustryRobotics in the Food Industry, including Universal Robots UR20, ATI Robotics Solution, and ABB Industrial Robots, provide significant benefits to food manufacturing and processing.Universal Robots UR20 offers flexibility and ease of use for automation in food handling and packaging, increasing efficiency and productivity.ATI Robotics Solution provides advanced end-of-arm tooling technologies, enabling precise and adaptable gripping, sorting, and processing of food items.ABB Industrial Robots offer a wide range of robotic solutions tailored to the food industry, streaml

Contact Now

Use Of Robotics In Construction:The use of robotics in construction, such as industrial arm machines like Omron SCARA and Kuka industrial robot arms, has revolutionized the industry. These robots offer several advantages in construction applications.Firstly, industrial arm machines enable precise and efficient material handling.

Contact Now

Robotics In Automobile Industry:Robotics in the automobile industry has revolutionized manufacturing processes. With the integration of advanced robotic systems, tasks in assembly lines have become more efficient and precise. Kuka Robot Price refers to the pricing of Kuka robots, which are widely used in the automotive sector for their reliability and versatility. These robots offer a range of models and configurations to suit different manufacturing needs.

Contact Now

Robotics Solution In Apparel Industry:Robotics in the apparel industry has revolutionized the way clothes are manufactured. With the use of automated machines, the process has become faster and more efficient, resulting in higher productivity.Meat processing robotics has also made a significant impact in the food industry. These robots are capable of performing tasks such as cutting, deboning, and packaging, which not only saves time but also ensures consistent quality and safety standards.CNC machine loading robots have simplified the manufacturing process in various industries.

Contact Now

Use Of Mobile Robotics In Different Industries:Mobile robotics technology is being increasingly used in various industries to enhance efficiency and productivity. In the manufacturing sector, industrial robotic arm manufacturers such as ABB, Fanuc, and KUKA are leading the way in providing advanced robotic arms that can perform precise and repetitive tasks.Another application of mobile robotics is in the packaging industry, where robotic packaging equipment is becoming the norm.

Contact Now