Robotic Car Manufacturing:Robotic car manufacturing has revolutionized the automotive industry. With the integration of advanced technologies, such as the Kuka Robot Arm, the process has become more efficient and precise. These robot arms are capable of performing various tasks, including welding, assembly, and painting, contributing to streamlined production.Process automation robotics plays a crucial role in automating repetitive tasks in car manufacturing, reducing human error, and increasing overall productivity.

Contact Now

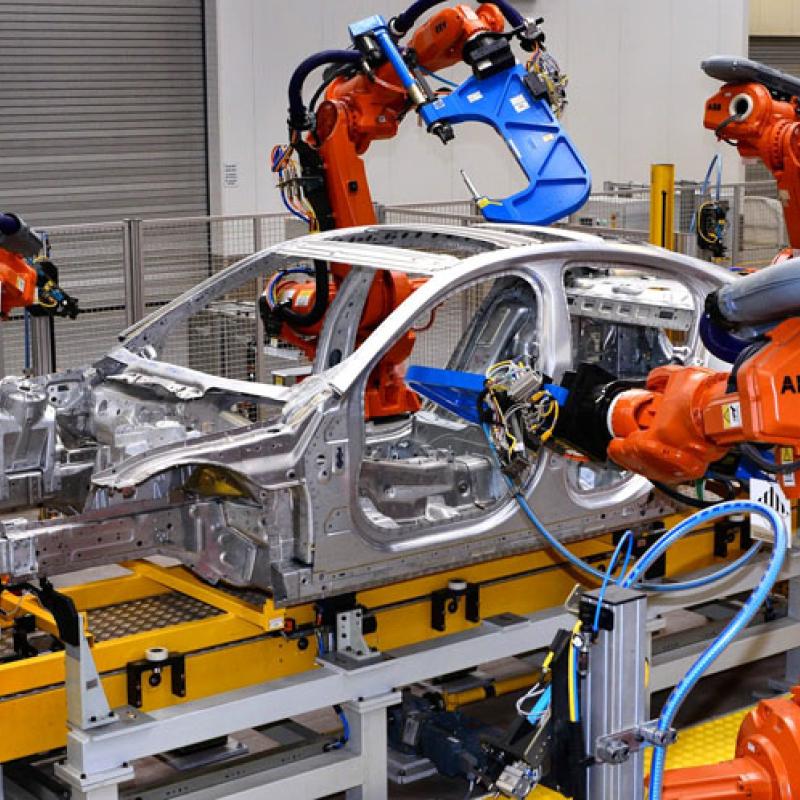

Robot Car Assembly Line:The use of robot car assembly lines in car manufacturing has numerous advantages. Robots ensure precision and accuracy, resulting in high-quality vehicles. They work faster than humans, increasing productivity. Moreover, robots work consistently without fatigue or distractions, improving efficiency. They also take over dangerous tasks, enhancing worker safety. A video showcasing a robot car assembly line displays the precise movements and speed of the robots.

Contact Now

Welding Robots Car Assembly:Welding Robots in car assembly, powered by the Kuka Krc5 Controller, have revolutionized the manufacturing industry. Equipped with a manipulator robot arm, these robots offer numerous advantages. They provide fast and efficient production rates, ensuring increased productivity. With precise programming and advanced sensors, they deliver accurate and consistent welding, resulting in high-quality welds. In addition, these automation solutions ensure worker safety by eliminating the risks associated with manual welding.

Contact Now

Automated Car Assembly Line:The automotive industry has been revolutionized by the introduction of automated car assembly lines. The use of automated robots to perform most assembly tasks has greatly improved production efficiency and reduced error rates and human losses. For instance, the Auto Assembly Line integrates various machines to ensure the process is automated and standardized, and that workers can focus on their tasks. The entire production process is smooth and seamless, making it possible to produce high-quality components with precision and accuracy.

Contact Now

Automated Car Assembly Line:Automated Car Assembly Line, Kuka Youbot Arm, Abb Yumi Robot Manual, and Joseph Engelberger Robots are significant advancements in industrial robotics. The assembly line streamlines car manufacturing, reducing costs and improving efficiency. The Kuka Youbot Arm performs various tasks with precision. Abb Yumi Robot Manual enhances productivity and safety through collaboration. Joseph Engelberger Robots honor a pioneer in robotics, shaping the future of automation. These innovations continue to revolutionize industries, boosting productivity and driving progress.

Contact Now

Automated Car Assembly Line:The Top Automobile Industry In World is leading the way in implementing innovative technologies to improve production and reduce costs. One such technology is Automated Production Line Examples, which enable companies to operate 24/7 without interruptions. The world no 1 car company has invested heavily in this technology, recognizing the benefits of reduced labor costs, increased efficiency, and higher quality products. However, this technology does come with some challenges, such as initial costs and potential employee resistance.

Contact Now

Robotic Car Production Line Solution:The use of a robotic car production line in the automotive industry has its advantages, but also some disadvantages. While robots offer precision and efficiency, they lack adaptability for complex and custom tasks. The initial investment and maintenance costs can be high, which may limit smaller manufacturers. Programming and reprogramming robots can also be time-consuming and requires specialized skills. Despite these drawbacks, the future of robotics in the automotive industry remains promising.

Contact Now

Robotic Arm In Car Manufacturing Solution:The use of robotic arms in car manufacturing has revolutionized the automotive industry. In China, robot car manufacturers are leading the way in increasing efficiency and productivity. With robots integrated into the assembly line, precision and accuracy are enhanced, leading to higher quality cars being produced. The automotive industry worldwide is realizing the benefits of robots in the manufacturing process. From welding to painting, robots are proving to be indispensable in the automotive industry.

Contact Now

Fully Automated Assembly Line:Fully automated assembly lines have become increasingly popular in modern manufacturing facilities due to their numerous advantages. An auto assembly line is a prime example of such a mechanism, allowing for the completion of a large number of tasks through reduced manual operations and increased automation, hence improving its consistency and quality output. Auto assembly plants across the world, such as the Auto Assembly Plant Mexico, have been embracing this technology in efforts to optimize their respective manufacturing processes.

Contact Now

Robotic Arm In Automotive Industry Solution:The automotive industry has witnessed significant advancements with the integration of robotic arms. Robotic arms have become an integral part of car factories, shaping the future of the industry. These powerful machines are utilized in various stages of production, from assembly to painting, ensuring precision and efficiency. In China, the use of robots in car factories has revolutionized the car manufacturing process.

Contact Now

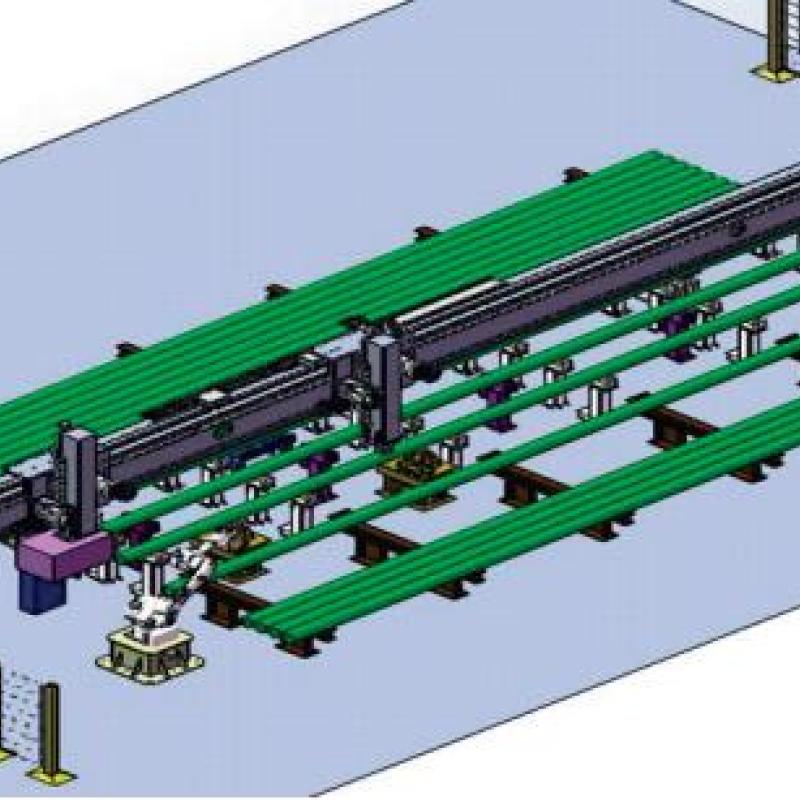

This assembly line is a versatile automated manufacturing line, which realizes the automated meeting of steerage knuckle meeting for heavy vehicles via way of means of the usage of a six-axis robot, 2D imaginative and prescient system, 3-D imaginative and prescient system, and servo press. It is well suited with the automated manufacturing of greater than twenty varieties of guidance knuckle products. There isn't anyt any guide operation role withinside the line, that could meet the manufacturing of the unique shape guidance knuckle and different vehiclemobile parts.

Contact Now

This assembly line is a flexible automatic production line, which realizes automatic assembly of V-type thrust rod assemblies for heavy trucks by using six-axis robots, 2D vision systems, 3D vision systems, and servo presses. It is compatible with the automated production of many kinds of V-type thrust rod and other auto parts assembly products. The line is equipped with manual operation positions to meet the production of special structure thrust rod assemblies.

Contact Now

Robot Car Body Spot Welding:Robot Car Body Spot Welding has become increasingly popular in the automotive industry. Manufacturers like Kuka Roboter GmbH have developed advanced 6 Degree of Freedom (6 DOF) Robotic Arms for this purpose. These robotic arms are programmed using Arduino code to perform precise spot welds on car bodies.To ensure seamless operations, companies like ABB Robot offer excellent tech support to troubleshoot any issues that may arise during the welding process.

Contact Now

Robot Car Body Welding:Robot car body welding has revolutionized the automotive industry. It offers numerous advantages in terms of efficiency, precision, and safety. Manufacturers like Kuka Group Input have embraced this technology, leveraging the speed and productivity of robots to increase production rates. These robots perform welding tasks with immense precision, ensuring consistent and high-quality welds on car bodies. The use of robots also promotes safety by eliminating the need for human operators to handle hazardous welding tasks.

Contact Now

Robotic Car Chasis Automatic Welding Line The integrated system integrates automatic feeding, welding clamping, automatic welding, automatic loading and unloading, intelligent management, and detection into a single unit.It enables the complete automation of the entire automotive welding line and achieves digital processing in an unmanned workshop. The system consists of a six-axis robot, an identification and positioning system, a welding fixture system, an intelligent positioner system, and a safety protection system.

Contact Now

It is a fully automatic flexible assembly line, which can complete automatic assembly of axle holes with very small fit gaps by using six-axis robots, 2D vision system, and 3D vision system, and is compatible with a wide range of specifications. This production line is the first of its kind in the world to achieve fully automatic flexible assembly of automotive parts such as differentials for heavy trucks.DSCS-375ALProduct assembly weight: ≤ 80 kg;Assembly clearance of shaft hole: ≥ 0.02mm.

Contact Now

This assembly line is a flexible automatic production line, which realizes the automatic assembly of steering knuckle assembly for heavy trucks by using a six-axis robot, 2D vision system, 3D vision system, and servo press. It is compatible with the automatic production of more than twenty kinds of steering knuckle products. There is no manual operation position in the line, which can meet the production of the special structure steering knuckle and other auto parts.

Contact Now

Robot Technology In Car Manufacturing Solution:Robot technology has played a crucial role in revolutionizing car manufacturing. China, being one of the largest automobile manufacturers, is at the forefront of utilizing robots in their car factories. These robots are used in various aspects of the manufacturing process, from assembling car parts to quality control. By incorporating robots in car factories, production efficiency has significantly increased, allowing for shorter lead times and cost savings.

Contact Now

Robots For Car Body Welding:Robots for car body welding, such as the Kuka KRC2, offer numerous advantages in terms of precision, efficiency, and safety. These robots ensure consistent weld quality with minimal errors due to their high accuracy. They can work tirelessly without fatigue, resulting in increased productivity and reduced cycle time compared to manual welding. Moreover, using robots for welding tasks enhances the safety of workers by minimizing their exposure to harmful fumes, sparks, and heat.

Contact Now

Robot Welding a Car:In the manufacturing industry, robot welding has emerged as a game-changing technology. When it comes to assembling cars, Robot Welding a Car offers numerous advantages. It enhances precision by ensuring consistent and accurate welds, resulting in stronger connections between car parts. The use of robots also increases efficiency, as they can work continuously without breaks or fatigue, reducing cycle times and boosting overall productivity. Moreover, robot welding promotes safety in the workplace by eliminating the need for human operators to perform hazardous tasks.

Contact Now

The assembly line is a flexible automatic production line. Tie Rod Assembly Line Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.By using six-axis robots, 2D vision system, 3D vision system, and servo tightening machine, it realizes automatic buckle clearing, coding, clamping, and assembly of auto parts such as cross ties for heavy trucks. It is compatible with the automatic production of more than ten kinds of products.

Contact Now

Robotic Arm Welding Car:Robotic Arm Welding Car has become a game-changer in the automotive industry. Manufacturers like Kuka and ABB have developed advanced robotic arms, such as the Kuka KR210 and ABB Robot Arm, capable of performing precise and efficient welding tasks. These arms, guided by manual programming like the Kuka KR210 manual, ensure accuracy and consistency in welds.However, the benefits of robotic arms extend beyond the automotive sector. These versatile machines are also utilized in unconventional applications like mining.

Contact Now

Robots For Car Body Welding:The world's largest automobile industry is increasingly turning to automated production lines to increase efficiency and output levels. However, it is essential to consider the potential advantages and disadvantages of the automated production process.

Contact Now

Welding Car Manufacturing Robots Solution:Welding Car Manufacturing Robots, such as those produced by Kuka, have revolutionized the automotive industry. Welding Car Manufacturing Robots Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.These robots offer numerous advantages, including increased efficiency, enhanced accuracy, and improved safety. With continuous work capabilities, they boost productivity and reduce production time, surpassing human welders.

Contact Now