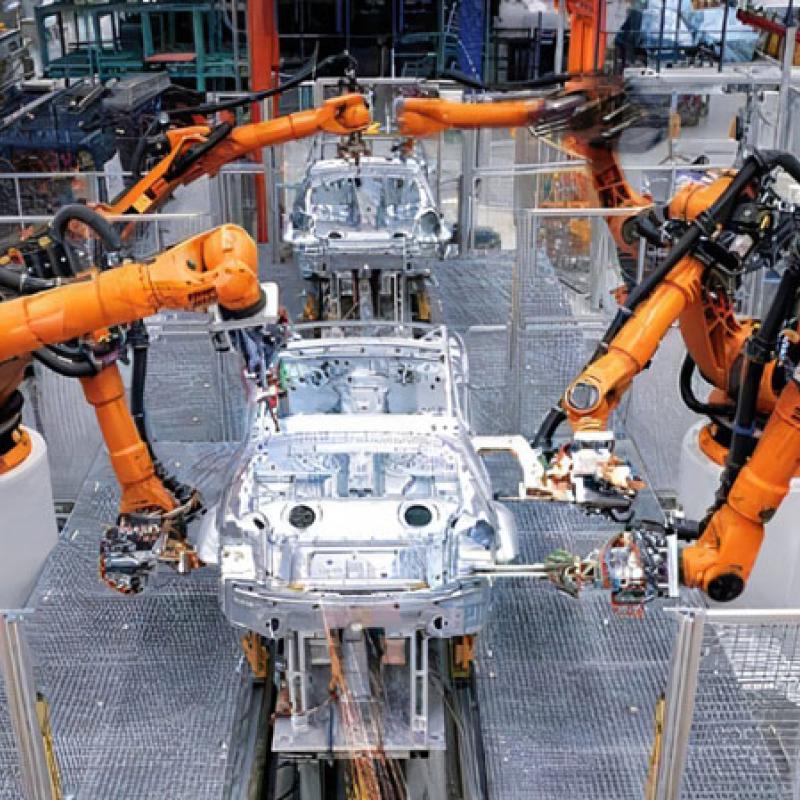

Robot In Automotive Industry Solution:Robots play a crucial role in the automotive industry. Their use in car manufacturing offers several advantages. Robots provide precision and accuracy, ensuring high-quality vehicles. They are efficient and can work at a faster pace than humans, increasing productivity. They excel at repetitive tasks and can work consistently without fatigue. Moreover, robots can perform hazardous jobs, enhancing worker safety. Some common robot applications in the automotive industry include welding, painting, and assembly. However, there are also some disadvantages.

Contact Now

Articulated Robot Applications:Articulated Robot Applications offer numerous advantages in various industries. The KUKA KR 30 R2100 is a notable example of an articulated robot that excels in precision and versatility. Its multiple joints and high accuracy make it ideal for tasks in automotive manufacturing and electronics assembly. Another noteworthy robot is the BCN3D Moveo Robot, known for its open-source nature and educational value. It allows users to learn and experiment with robotics while improving their technical skills.

Contact Now

Cobots In Automotive Industry:The automotive industry has been facing a crisis due to the changing market demands and the impact of the pandemic. To mitigate the impact, many companies are turning to automated production line systems. The world's No. 1 car company is also leveraging this technology to maintain production levels and improve efficiency while reducing labor costs. They are using cobots - collaborative robots that work alongside human operators and can perform a wide range of tasks.

Contact Now

Robotic Arm In Automotive Industry Solution:The automotive industry has witnessed significant advancements with the integration of robotic arms. Robotic arms have become an integral part of car factories, shaping the future of the industry. These powerful machines are utilized in various stages of production, from assembly to painting, ensuring precision and efficiency. In China, the use of robots in car factories has revolutionized the car manufacturing process.

Contact Now

Parts Of An Industrial Robot:The Kuka Kr 300 2 Pa is a popular industrial robot that belongs to the Kuka brand. It is equipped with various parts to perform its tasks efficiently. Some of the essential parts of this robot include the robot arm, gripper, controller, sensors, and actuators. The robot arm is responsible for the movement and manipulation of objects. The gripper is used to grasp and hold the objects securely. The controller acts as the brain of the robot, allowing it to execute precise movements. Sensors enable the robot to sense its surroundings and adapt accordingly.

Contact Now

Non Industrial Applications Of Robots:Robots have become an integral part of our lives, not just in industrial settings but also in various other fields. One such example is the Mir Mobile Robot, which is designed to assist in healthcare facilities. It can transport medical supplies and equipment, reducing the workload of healthcare professionals and ensuring efficient delivery.Another non-industrial application of robots is the DIY Scara Robot.

Contact Now

Robotics For Automotive Industry Solution:Robotics plays a vital role in the automotive industry, particularly in car manufacturing. The use of industrial robots in this industry brings numerous benefits. Industrial robots are highly efficient and precise, ensuring consistent and high-quality production. They can perform a range of tasks, such as welding, painting, and assembly with speed and accuracy. Moreover, these robots enhance worker safety by handling hazardous and repetitive tasks. Their versatility and flexibility make them valuable assets in optimizing production processes.

Contact Now

Robotics In Automotive Manufacturing Solution:The automotive manufacturing industry has witnessed a significant transformation with the integration of robotics. Robotic arms have become an essential part of car manufacturing, revolutionizing the production process. With their precise movements and capabilities, robotic arms contribute to increased productivity, higher quality, and improved safety. These advanced machines perform tasks such as welding, assembly, and painting with unparalleled accuracy and efficiency.

Contact Now

Advantage Of Using Robot In Industries:The advantages of using robots in manufacturing industries are increased productivity, improved product quality, and reduced labor costs. Robots excel at repetitive tasks and can work consistently without getting tired. They can also handle dangerous or hazardous tasks, ensuring the safety of human workers. DIY industrial robot kits provide an opportunity to learn and explore robotics, improving skills and knowledge.

Contact Now

Industrial Robotic Automation:Robot in Steel Industry: The inclusion of robots in the steel industry has revolutionized the way work is carried out. With their precision and efficiency, robots have become an integral part of industrial operations. Whether it is welding, cutting, or handling heavy materials, industrial robots have proven to be highly effective.Industrial Robot Working: The working of industrial robots involves a combination of advanced sensors, programming, and mechanical components.

Contact Now

Articulated Robot Applications Series:Articulated Robot Applications Series, Best 110v Stick Welder, Lincoln Portable Welder, and Miller Aluminum Welder are all exceptional tools and equipment for those involved in welding processes.The Articulated Robot Applications Series boasts numerous advantages, including flexibility, versatility, and efficiency. With multiple joints and segments, these robots can maneuver in various motions, making them ideal for complex and precise welding tasks.

Contact Now

Robot Welding Technology Ppt:Robot Welding Technology PPT, KUKA KR 30 R2100, BCN3D Moveo Robot, and Robotic Warehousing Arm are all innovative technologies that have transformed various industries.The Robot Welding Technology PPT provides a comprehensive overview of the benefits and applications of robot welding. It educates users on the advantages of automation, improved efficiency, and enhanced quality in welding processes.The KUKA KR 30 R2100 is a versatile industrial robot that excels in welding applications.

Contact Now

Need Of Robots In Industries:Robots have become an indispensable component in various industries today. The need for robots in industries arises from their ability to perform tasks efficiently, accurately, and tirelessly. They contribute to increased productivity, reduced labor costs, and improved product quality.Understanding the fundamentals of robot technology is essential for its successful implementation. It involves knowledge of programming, sensors, actuators, and control systems.

Contact Now

Robot Painting Cars:Robot painting cars has become a common practice in the automotive industry. With advanced robotic systems, the process has become more efficient and precise. Kuka AG Annual Report 2022 provides insights into the performance and achievements of Kuka AG, a leading robotics company involved in automotive applications. Additionally, Cachorro Quente UR5 refers to the use of UR5, a collaborative robot, in hot dog preparation. This showcases the versatility of robots in various industries.

Contact Now

Robots Used In Automobile Industry:Robots have become an integral part of the automobile industry, revolutionizing production processes. One popular controller used in automotive robotics is the Kuka KRC4 Controller, known for its precision and reliability. Additionally, the emergence of 3D printing technology has allowed for the creation of innovative robot arms that are cost-effective and customizable. The Unimate Robot Arm, introduced in the 1960s, was one of the first industrial robots used in car manufacturing.

Contact Now

Robot In Welding Industry:Robot in Welding Industry, KUKA CEE GmbH, ABB YuMi Robot Model, and Rapid Robotics Yaskawa are all cutting-edge technologies that have revolutionized the welding industry.Robot in Welding Industry has significantly increased efficiency and productivity in welding processes. It automates repetitive tasks, allowing for faster production cycles and consistent weld quality.KUKA CEE GmbH is a leading provider of robotic solutions for welding applications.

Contact Now

Robotics In Automobile Industry:Robotics in the automobile industry has revolutionized manufacturing processes. With the integration of advanced robotic systems, tasks in assembly lines have become more efficient and precise. Kuka Robot Price refers to the pricing of Kuka robots, which are widely used in the automotive sector for their reliability and versatility. These robots offer a range of models and configurations to suit different manufacturing needs.

Contact Now

Robot In Petroleum:The integration of robots in the petroleum industry has revolutionized operations, enhancing efficiency and safety. Kuka ROS Industrial is a leading provider of robotic solutions, offering cutting-edge technology for various applications. When considering robotic arm prices, it's essential to evaluate the specific requirements and functionalities needed. SCARA robot arms, known for their speed and precision, are a popular choice in many industries.

Contact Now

Robot In Petroleum Industry:The integration of robotics in the petroleum industry has revolutionized operations, enhancing efficiency and safety. One notable example is the KCP KUKA KRC4 system, which combines advanced technology with industrial manipulator arms.The KCP KUKA KRC4 system offers precise control and flexibility, allowing it to perform various tasks in the petroleum industry.

Contact Now

Type Of Industrial Robot:Industrial robots, including Industry Robot, labeling robot, and automatic label spot welding robot, have made significant advancements in recent years through Scara Robot Applications, Cartesian Robot Control System, and enhancements in articulated robots. These cutting-edge technologies offered numerous benefits, such as improved efficiency, productivity, accuracy, and safety in the industrial setting.The Industry Robot and labeling robot can automate repetitive tasks in industrial production lines, enabling faster and more efficient processes with minimal downtime.

Contact Now

Automotive Assembly Line Robots:Automotive assembly line robots, such as the Air Skin Kuka, offer several advantages in terms of efficiency, precision, and safety. These robots are capable of working tirelessly without fatigue, ensuring continuous production and increased productivity on the assembly line. With their high accuracy and consistent movements, they contribute to improved product quality and reduced errors in assembly tasks.The Air Skin Kuka is a remarkable example of a 6-axis robot arm that can be utilized for various automotive assembly applications.

Contact Now

Robots In Packaging Industry Solution:Robots have increasingly become an integral part of the packaging industry, revolutionizing the way products are packaged. The advantages of robot packaging are numerous. Firstly, robots excel in speed and efficiency, allowing for faster packaging processes and increased production capacity. Additionally, the precision and accuracy of robotic packaging ensure consistent and high-quality packaging results. ARp Automation is a leading provider of robotic packaging solutions, offering advanced technology and expertise in automating packaging processes.

Contact Now

Automotive Assembly Line Robots:Automotive assembly line robots are revolutionizing the automobile industry by providing several benefits. These robots perform tasks with precision and speed, resulting in increased efficiency and productivity.

Contact Now

Robot In Petroleum Industry Solution:In the petroleum industry, the use of robotics has provided numerous advantages. Inspection robotics plays a vital role in the oil and gas industry by ensuring the safety and efficiency of operations. These robots are designed to perform inspections in hazardous environments, such as pipelines, tankers, and offshore platforms, reducing the risk for human workers. Robotics technology also allows for increased accuracy and efficiency, leading to improved productivity.

Contact Now