The device is mainly used in laboratory automatic processing and mechanical (magnetic) performance testing systems for cold-rolled steel coils such as common cold, galvanized electroplated tin, and silicon steel samples, to replace the traditional processing mode of low production efficiency and heavy load. According to the test requirements, the sample preparation requirements are obtained from the sample information. The areas that need to be sampled are marked by laser, coding, or labels.

Contact Now

The system is mainly used in the field of metallurgical steel coil products, and it is used to tape and label the coil after winding. Based on the labeling robot, the function is optimized, and the function of sticking tape is integrated. Added tape fixed-length cutting device, tape special suction cup, pressure roller, tape tail detection, and other functions.DSBD-NJ02Coil diameter: φ800 ~ φ2100mm;Steel coil width: 800 ~ 1650mm;Labeling position: inner ring and outer ring;Adhesive tape position: tape tail;Label size: 100mm × 200mm.

Contact Now

IFR Robotics - Revolutionizing Automation Technology:In the realm of automation, IFR Robotics is leading the charge. Their innovative solutions are revolutionizing control automation, enhancing efficiency across various industries. In the automated material handling market, their advanced systems are transforming processes, ensuring precision and speed. Moreover, their lab automation engineers are pioneering new ways to streamline laboratory operations, reducing manual labor and error.

Contact Now

Demolition Robots In Construction:Demolition Robots in Construction, as highlighted in the "IFR World Robotics 2022" report, have revolutionized the industry. With advanced features and technology, robots like the ROS Motoman and Kuka KR 3 R540 offer cutting-edge solutions. These robots are specifically designed for demolition tasks, allowing for precise and controlled dismantling of structures. Equipped with powerful tools, they ensure safe and efficient operations, reducing human risks and increasing productivity.

Contact Now

Yamaha Scara Robot PriceThe Yamaha Scara Robot Price, coupled with the new robot technology anticipated for 2022, leaves us in awe. Reflecting on the past, we cannot forget the pioneering Unimation Company, which ignited the robotics revolution. As per World Robotics 2021, industrial robots are thriving. Exciting times lie ahead as we witness remarkable advancements in the realm of robotics.

Contact Now

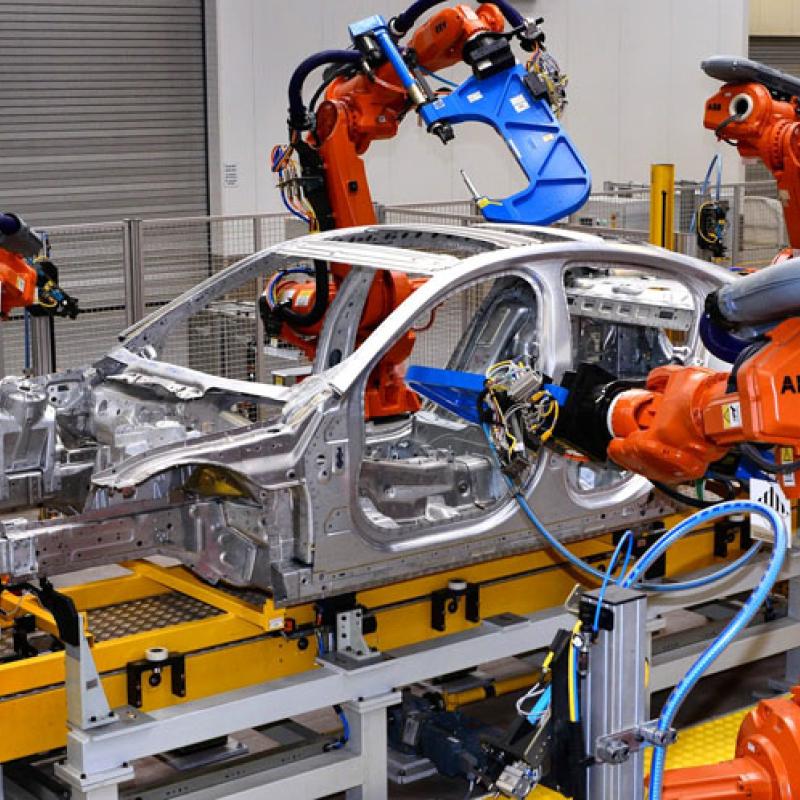

Robot Technology In Car Manufacturing Solution:Robot technology has played a crucial role in revolutionizing car manufacturing. China, being one of the largest automobile manufacturers, is at the forefront of utilizing robots in their car factories. These robots are used in various aspects of the manufacturing process, from assembling car parts to quality control. By incorporating robots in car factories, production efficiency has significantly increased, allowing for shorter lead times and cost savings.

Contact Now

Wiautomation AuWiautomation AU, coupled with the impact of robotics in aerospace engineering, offers significant advantages. Wiautomation AU provides a wide range of automation solutions, including robotics, to cater to the specific requirements of the aerospace industry. The Kuka Kr 360, available through Wiautomation AU, offers high precision and versatility, making it suitable for complex aerospace applications. Additionally, the use of painting robots in industries, facilitated by Wiautomation AU, enhances efficiency and quality in the painting process.

Contact Now

Coupling Finishing Machine1. Steel pipe is clamped with a double-chuck shape, and the pneumatic chuck adopts an imported big-diameter chuck. the clamping and loosening of the chuck can most effective be performed while the spindle stops. under the movement of the air manage take a look at valve, the air pressure inside the clamping cylinder stays unchanged and the movement is reliable.2. Hydraulic servo tool holder adopts the device holder imported from italy, with speedy and solid indexing, no lifting mechanism, massive diameter toothed disc, excessive precision and large locking pressure.3.

Contact Now

The unique air knife generation is used to make the compressed air frivolously and annularly spray at the floor of the metallic pipe thread, with a view to blow off the emulsion and scrap iron at the floor of the inner or outside thread, and it's far ready with a waste water restoration device.DSCS-7/13/20WSteel pipe specification: 7 ""/13 ""/20 ""

Contact Now

The special air knife technology is used to make the compressed air evenly and annularly spray on the surface of the steel pipe thread, so as to blow off the emulsion and scrap iron on the surface of the internal or external thread, and it is equipped with a waste water recovery device.DSCS-7/13/20NSteel pipe specification: 7 ""/13 ""/20 ""

Contact Now

The Unimate - A Revolutionary Robot:The Unimate, a revolutionary robot, has paved the way for automation robotics, transforming industries globally. With its innovative capabilities, it has revolutionized manufacturing processes, increasing productivity and efficiency. Alongside other robotics and automation companies, the Unimate has played a crucial role in driving advancements in the field. Nidec Automation, in particular, has emerged as a key player in Industry 4.0.

Contact Now

The Hi Tech Robotic Systemz:The Hi Tech Robotic Systemz is a leading provider of advanced robotic solutions. They compete with companies like ABB, known for their ABB IRB 1300 series, and KUKA, a renowned manufacturer. These companies offer a range of industrial robots for sale, catering to diverse industries. Customers can choose the most suitable option based on their needs and budget. With their precision, speed, and flexibility, these robots revolutionize automation processes and enhance productivity.

Contact Now

Automatic Zinc Slag Salvaging RobotDevice Description/ Instruction: The equipment can realize automatic salvage of scum in galvanized zinc pool of steel plate. The scum in the zinc pool is concentrated to the designated area by manual slag removal, and the six-axis robot automatically salvages the scum in the area. The equipment is equipped with a liquid level measuring device, which can automatically adjust the slag fishing trajectory according to the change of the zinc liquid level.

Contact Now

Automatic Unbundling RobotDevice Description/Instruction:The device automatically removes the strapping on the steel coil using a six-axis robot and a special stripping mechanism. It can significantlyimprove the efficiency of on-site tape removal, reduce labor, and avoid potential safety hazards.

Contact Now

Automatic Painting RobotThe International Federation of Robotics (IFR) is a global organization that promotes the use of automation in various industries. One of the leading companies in this field is SLK Automation, which specializes in the development and production of automatic painting robots. These robots are designed by Kuka Manufacturing, a renowned manufacturer of industrial robots.With the help of automatic painting robots, industries can achieve higher productivity and efficiency in their painting processes.

Contact Now

Welding Using Robotic Arm:Welding using robotic arms has gained popularity in various industries. Robot Kuka Mexico and Fanuc Laser Robot are leading providers of advanced robotic systems for welding applications. These robots offer precise and efficient welding capabilities, delivering high-quality welds consistently.Additionally, pick and place robots play a vital role in the welding process by handling and positioning the workpieces accurately, ensuring seamless welding operations.

Contact Now

Robotic Welding Machine Manufacturers:Robotic welding machine manufacturers are constantly pushing the boundaries of technology to create more efficient and precise welding processes. These machines are equipped with robotic arms that can perform complex movements and weld with incredible accuracy.In addition to welding, robotic arms are also used in packaging applications. They can pick up products and place them in boxes or containers with speed and precision.

Contact Now

Efficient Intelligent Welding Automation has brought about major improvements in the welding industry, Robot Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.With robotic welding arms and pipe welding robots leading the way. These machines offer faster welding times and higher precision, leading to increased productivity and efficiency. While the initial cost of a robotic welding machine may be significant, their ability to reduce labor costs allows for a quick return on investment.

Contact Now

Fanuc Tig Welding RobotFanuc Tig Welding Robot is a state-of-the-art robotic Tig welding machine equipped with a robotic Tig welding torch. This advanced technology revolutionizes the welding industry by offering precise and efficient welding solutions.The Fanuc Tig Welding Robot combines the precision and skill of a human welder with the speed and accuracy of a machine. It is programmed to perform complex welding tasks with utmost precision, ensuring high-quality welds every time.The robotic Tig welding machine is equipped with a Tig welding torch that can be controlled remotely.

Contact Now

Carbon Block Distributed Task Allocation Robots:Carbon Block Distributed Task Allocation Robots are state-of-the-art robots that can efficiently allocate tasks among themselves, resulting in increased productivity. Among the many types of robots available, a Wall Painting Robot is especially useful for painting large areas quickly and accurately. Automated Robotic Machinery, on the other hand, is essential for mass production and can significantly cut down on labor costs.

Contact Now

Carbon Block Task Allocation Robots:The use of robotics technology continues to evolve in many industries across the globe. One of the most innovative developments in this field is the use of Carbon Block Task Allocation Robots in carbon block production. These robots are equipped with high-precision sensors and advanced programming, ensuring accurate measurement and positioning of carbon blocks, and ultimately improving the quality of the end product.The Carbon Block Task Allocation Robots are an evolution of the Unimate Robot Arm, which was the first-ever industrial robot.

Contact Now