Automated welding systems, along with the use of underwater welding robots, are revolutionizing the welding industry. Automatic welding has significantly increased productivity while also improving the quality of the weld. The use of an auto feed TIG welder further increases this efficiency as it allows for continuous welding without the need for stopping and starting. This automation not only saves time and money but also reduces the risk of human error and injury.

Contact Now

Advanced Efficient Energy Robotics:Advanced Efficient Energy Robotics is a cutting-edge technology that is revolutionizing the manufacturing industry. They are highly efficient, precise, and energy-saving robots that use intelligent energy-saving technology to reduce energy consumption and promote a sustainable environment.To fully leverage the capabilities of Advanced Efficient Energy Robotics, welding professionals rely on superior products like Everyday Welding Supplies, Miller 350p Manual, and Best 110v Mig Welder.

Contact Now

Automated Palletizing Robot:Automated Palletizing Robot, such as Yaskawa Industrial Automation's Palletizing Robot for Boxes, offered by Automation Robotics and Controls Inc, brings numerous advantages to the palletizing process. These robots significantly increase efficiency by operating at a faster pace, without the need for breaks or shifts. With precise stacking capabilities, the robot ensures accurate placement and alignment of items on the pallet.

Contact Now

Automated Automotive Assembly Line:An automated automotive assembly line, equipped with machines and robotics, ensures accurate, reliable, and efficient production of automobiles by reducing manual labor. Auto Assembly Line Photos show how machines work tirelessly, achieving a higher output rate in a shorter time frame without breaks. Automated Assembly Line Definition highlights the built-in quality control measures to ensure every product is made to the highest standards.

Contact Now

Automatic BIW Production Solution We develop and supply turnkey Production Systems for assembling body parts. The processes and production equipment are fully tailored to our customers' wishes and requirements.These projects tend to be highly automated production lines on which a mixture of different models can generally be produced.The lines are designed to produce several hundred to over 2,000 cars a day.

Contact Now

Automated Welding Robots For CarsAutomated welding robots have revolutionized the car manufacturing industry. Companies like Yaskawa and Kawasaki have developed advanced robot welding systems that are widely used in car production.Yaskawa's robot welding technology ensures precise and efficient welding of car components. With their high-speed and accurate movements, these robots can weld various parts of a car, including the chassis, body panels, and exhaust systems.

Contact Now

High-Speed Automated Palletizing Robot:High-Speed Automated Palletizing Robot, GMAW (Gas Metal Arc Welding), PVC welding equipment, and the Primeweld 225 welding machine are all examples of advanced automation technology that have revolutionized multiple industries.

Contact Now

Intelligent Efficient Welding Robot is one of the most active fields of industrial robot and can be used in a variety of applications. One of these applications is the use of robotic welding cells, where welding robots work alongside other machines to improve efficiency. Additionally, there is a market for used welding robots for sale, providing an economical option for businesses looking to invest in robotic technology.

Contact Now

Automated Robotics In Logistics:Automated Robotics in Logistics and Robotic Assembly Solutions are two innovative technologies developed by Rockwell Automation Company. These solutions have revolutionized the logistics and manufacturing industries by streamlining processes and increasing efficiency. With the help of Human Machine Interface (HMI), operators can easily control and monitor these robotic systems, ensuring smooth operations.

Contact Now

Automated Collaborative Factory Robots:Automated Collaborative Factory Robots are transforming production lines worldwide, and German Car Companies are no exception. The latest news in Autonomous Vehicle News highlights the partnership between German Car Companies and Automotive Parts Suppliers in implementing the latest in automated robotic technology. Through their collaboration, these companies are reducing production cycles, improving accuracy and precision, and maintaining high standards of quality.

Contact Now

Steel Carbon Automated Labeling Robot Solution:Robot Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.The Steel Carbon Automated Labeling Robot is a cutting-edge solution for labeling applications.

Contact Now

Efficient Intelligent Welding Automation has brought about major improvements in the welding industry, Robot Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.With robotic welding arms and pipe welding robots leading the way. These machines offer faster welding times and higher precision, leading to increased productivity and efficiency. While the initial cost of a robotic welding machine may be significant, their ability to reduce labor costs allows for a quick return on investment.

Contact Now

Automated Car Assembly Line:The automotive industry has been revolutionized by the introduction of automated car assembly lines. The use of automated robots to perform most assembly tasks has greatly improved production efficiency and reduced error rates and human losses. For instance, the Auto Assembly Line integrates various machines to ensure the process is automated and standardized, and that workers can focus on their tasks. The entire production process is smooth and seamless, making it possible to produce high-quality components with precision and accuracy.

Contact Now

Automated Car Assembly Line:The Top Automobile Industry In World is leading the way in implementing innovative technologies to improve production and reduce costs. One such technology is Automated Production Line Examples, which enable companies to operate 24/7 without interruptions. The world no 1 car company has invested heavily in this technology, recognizing the benefits of reduced labor costs, increased efficiency, and higher quality products. However, this technology does come with some challenges, such as initial costs and potential employee resistance.

Contact Now

KUKA Servo Robot:KUKA Servo Robots are revolutionizing small welding services near me. With their precision and versatility, they are the perfect fit for various welding needs. Coupled with a top-notch Thermal Arc Tig Welder, these robots produce high-quality welds consistently. And if you're looking for affordable options, Hobart Welders for sale provide reliable and cost-effective solutions. These welding machines and robots work seamlessly together, ensuring efficient and accurate results.

Contact Now

Automated Electronics Assembly Line:Automated Electronics Assembly Lines have revolutionized the manufacturing industry by providing numerous benefits that increase efficiency, accuracy, and cost savings. These assembly lines are crucial for the production of electronics, automobiles, and other complex products.Auto Assembly Line Ford, Auto Factory Assembly Line, and Automatic Production Line Machine Hs Code are some of the most advanced and widely used Automated Electronics Assembly Lines in the industry.

Contact Now

Fully Automated Assembly Line:Fully automated assembly lines have become increasingly popular in modern manufacturing facilities due to their numerous advantages. An auto assembly line is a prime example of such a mechanism, allowing for the completion of a large number of tasks through reduced manual operations and increased automation, hence improving its consistency and quality output. Auto assembly plants across the world, such as the Auto Assembly Plant Mexico, have been embracing this technology in efforts to optimize their respective manufacturing processes.

Contact Now

Automated Robotics In Logistics:Automated robotics in logistics have made a significant impact in streamlining operations and optimizing efficiency in the supply chain industry. With the development of sophisticated robots and specialized software, logistics companies can now automate repetitive tasks such as picking, packing, and sorting. This ensures faster processing times, fewer errors, and a reduction in labor costs.Auto assembly line robots are commonly used in the automotive manufacturing industry.

Contact Now

This assembly line is a versatile automated manufacturing line, which realizes the automated meeting of steerage knuckle meeting for heavy vehicles via way of means of the usage of a six-axis robot, 2D imaginative and prescient system, 3-D imaginative and prescient system, and servo press. It is well suited with the automated manufacturing of greater than twenty varieties of guidance knuckle products. There isn't anyt any guide operation role withinside the line, that could meet the manufacturing of the unique shape guidance knuckle and different vehiclemobile parts.

Contact Now

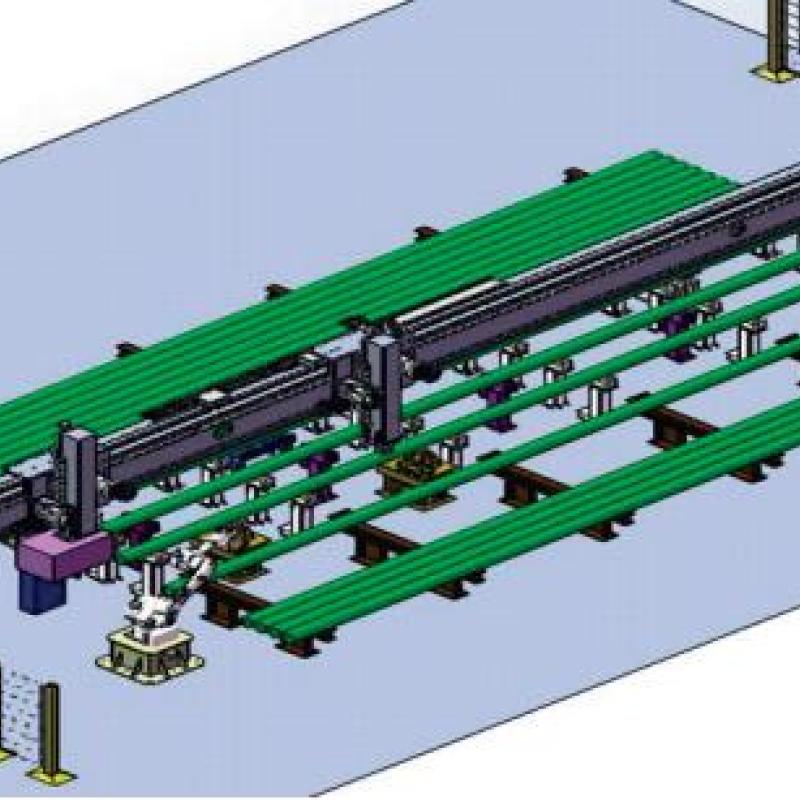

Automated Pipe Cutting Machine Solution:The Automated Pipe Cutting Machine, also referred to as the 45 Degree Pipe Cutting Machine or Aluminium Pipe Cutting Machine, is a remarkable invention that revolutionizes pipe cutting processes. This Auto Pipe Cutting Machine offers a range of advantages in terms of precision, efficiency, and safety. With its automated features, it ensures precise cuts, whether at a 45-degree angle or when cutting aluminium pipes. Moreover, its efficiency significantly increases productivity while reducing labor costs.

Contact Now

The portable welding workstation parameterized the skills and practical experience of senior welders, copied and migrated to the software side, and created a "0" threshold automation tool that can also be used by general workers. It greatly reduced the difficulty of welding technology, cracked the pain points of the welding industry, and made joint efforts in ease of use, versatility and safety, greatly expanded the application scenario of welding automation, and innovated the welding production mode.

Contact Now

Hi Tech Robotic Systemz Ltd:Hi Tech Robotic Systemz Ltd, High-speed Automated Packaging, and Control Automation Technology Sdn Bhd are among the top 50 automation companies of 2020. These companies excel in developing and implementing advanced automation solutions.Hi Tech Robotic Systemz Ltd is known for its expertise in autonomous systems, including autonomous vehicles and drones. They use cutting-edge technology to provide efficient and accurate solutions.High-speed Automated Packaging specializes in automated packaging solutions.

Contact Now

Robotics For Automotive Industry Solution:Robotics plays a vital role in the automotive industry, particularly in car manufacturing. The use of industrial robots in this industry brings numerous benefits. Industrial robots are highly efficient and precise, ensuring consistent and high-quality production. They can perform a range of tasks, such as welding, painting, and assembly with speed and accuracy. Moreover, these robots enhance worker safety by handling hazardous and repetitive tasks. Their versatility and flexibility make them valuable assets in optimizing production processes.

Contact Now