Rotary grinding is adopted to automatically position the pipe end, realize the positioning of the threaded pipe end and the grinding of the black leather buckle according to different specifications, and automatically recycle the scrap iron and dust generated by grinding.

Contact Now

Automatic black leather buckle removing and grinding equipmentPayment type:L/C, T/TIncoterm:FOB QingdaoMin. order: 1 setDelivery time : 30-50 working daysWarranty : 1 yearAfter-service: 24 hours online Rotary grinding is adopted to automatically position the pipe end, realize the positioning of the threaded pipe end and the grinding of the black leather buckle according to different specifications, and automatically recycle the scrap iron and dust generated by grinding.

Contact Now

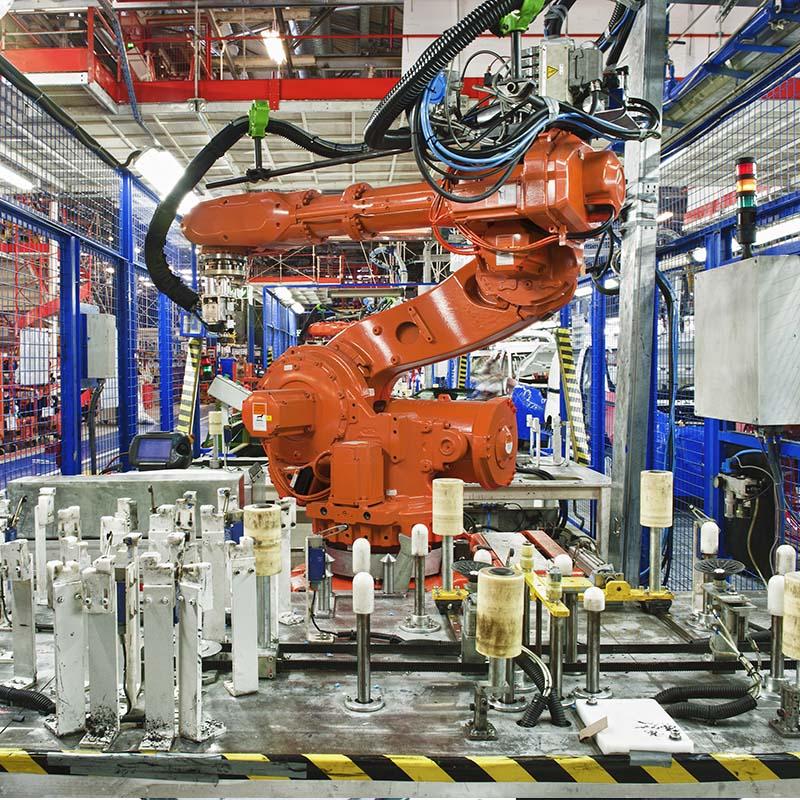

Desheng 3D Disordered Grabing/Grinding robotPayment type:L/C, T/TIncoterm:FOB QingdaoMin. order: 1 setDelivery time : 30-50 working daysWarranty : 1 yearAfter-service: 24 hours online In view of the irregular scene of incoming materials, the 3D vision system can be used to grasp the chaotic materials in disorder, and then realize the high-precision loading and unloading processing of products through automatic centering. After grasping, the system can support the machining center, loading and unloading, grinding, welding, spraying, fixed-point handling, and other

Contact Now

In the field of bare pipe processing, the application of automatic intelligent equipment such as automatic cap plugging robot, automatic code spraying robot and steel pipe end grinding robot is the first in the world in the field of petroleum bare pipe processing, filling the gap in the world.

Contact Now

This equipment is mainly developed for the existing market to meet the shortcomings of the automatic unpacking machine and a fully automatic unpacking and feeding machine for stacked bags of raw materials, which is suitable for the unpacking and feeding operation of various bags of raw materials. The first layer is used as the preparation area and the second layer is used as the loading work area, which does not occupy the workshop area and can make full use of the workshop space.

Contact Now

Robotic Mining Equipment:Robotic Mining Equipment, Industrial Robot Motor, ABB IRB6400RM2000, and Unimate First Industrial Robot are all innovative technologies that have revolutionized the mining and industrial sectors.Robotic Mining Equipment offers numerous advantages in the mining industry. These robots can navigate through hazardous and dangerous environments, reducing the risk to human workers.

Contact Now

In the circumferential direction of the steel coil, it automatically adapts to the outer diameter of the steel coil to complete the winding and pressing of the strip steel, preventing the steel coil from unraveling during transportation and storage. The equipment is suitable for steel belts and plastic belts.DSDK-ZX11Coil diameter: φ800 ~ φ2100mm;Steel coil width: 800 ~ 1650mm;Strapping form: circumferential direction.

Contact Now

Robotic Equipment Manufacturers:Robotic Equipment Manufacturers such as Kawasaki Industrial Robots, Kuka Kr 200, and Mir Agv Robot provide exceptional solutions for automation needs. Kawasaki Industrial Robots are known for their high performance and reliability, offering a wide range of robot models to suit various applications. The Kuka Kr 200, with its strong payload capacity, provides efficient handling and precise movements. Mir Agv Robot specializes in autonomous mobile robots, enabling flexible material transportation in industrial settings.

Contact Now

Robot Spot Weld Equipment:Robot Spot Weld Equipment, Kuka Kr5 Robot, and Niryo One Robot Arm are all innovative robotics technologies developed by Japanese robotics companies. These companies have been at the forefront of the robotics industry, constantly pushing boundaries and developing cutting-edge solutions.Robot Spot Weld Equipment is a state-of-the-art technology that automates the spot welding process, improving efficiency and precision.

Contact Now

Robotic Construction EquipmentRobotic construction equipment is a game-changer in the construction industry. With the help of top robotics companies in 2021, innovative solutions are revolutionizing construction processes. The implementation of the best welding robots significantly enhances efficiency and precision in welding operations, reducing errors and ensuring high-quality results. Moreover, robots are finding a place in the tourism industry, providing interactive and engaging experiences for visitors.

Contact Now

Robot Spot Welding Equipment:Robot Spot Welding Equipment, KUKA KR60 Manual, Hexbug Robot Arm, and Mecademic Meca 500 are all cutting-edge robotic technologies that have revolutionized various industries. These advanced machines have greatly enhanced productivity, precision, and efficiency in manufacturing processes.The Robot Spot Welding Equipment is a state-of-the-art system that automates the spot welding process, ensuring consistent and high-quality welds.

Contact Now

Desheng robot for Inner protective ring tightening:Model Specification of protective ring7 "/13"/20 "Maximum screwing torque200/400NMNumber of jaws5/6Screw connection form floating screw connectionClamping mode of protective ringexternal clamp or internal supportScrew connection distance tolerance of protective ring± 0.5mmThe inner and outer protective ring screwing robot equipment is the core equipment for petroleum pipe processing with a robot as the carrier in the industry at present, which can significantly improve the screwing performance of the protective r

Contact Now

Intelligent Bare Pipeline (Pipe Processing Intelligent Production Line)Device Description/Instruction: In the field of bare pipe processing, the application of automatic intelligent equipment such as automatic cap plugging robot, automaticcode spraying robot and steel pipe end grinding robot is the first in the world in the field of petroleum bare pipe processing, filling the gap in the world.

Contact Now

Carbon Steel Labeling Machine Equipment Solution:The carbon steel labeling machine equipment is a popular choice for industries due to its durability and reliability. It provides efficient and accurate labeling solutions for various products.When it comes to pricing, the automatic flat labeling machine is a cost-effective option. It offers high-quality labeling for flat surfaces at a competitive price point.For businesses in the food and beverage industry, the automatic jar labeling machine is a valuable investment.

Contact Now

Desheng Inner protective ring tightening robot:This products are mainly equipment in the field of pipe processing, mainly including intelligent processing equipment for casing lines, intelligent processing equipment for optical pipes and intelligent processing equipment for coupling lines.Specification of Inner protective ring tightening robot:Model:protective ring7 "/13"/20 "Maximum screwing torque200/400NMNumber of jaws5/6Screw connection formfloating screw connectionClamping mode of protective ringexternal clamp or internal supportScrew connection distance tolerance

Contact Now

Intelligent Bare Pipeline (Pipe Processing Intelligent Production Line)Device Description/Instruction:Steel pipe specification: 7 "/13"/20”;Steel pipe length: 6一12.5m.In the field of bare pipe processing, the application of automatic intelligent equipment such as automatic cap plugging robot, automatic code spraying robot and steel pipe end grinding robot is the first in the world in the field of petroleum bare pipe processing, filling the gap in the world.

Contact Now

The inner and outer protective ring screwing robot equipment is the core equipment for petroleum pipe processing with a robot as the carrier in the industry at present, which can significantly improve the screwing performance of the protective ring screwing process.

Contact Now

The equipment can realize automatic salvage of scum in galvanized zinc pool of steel plate. The scum in the zinc pool is concentrated to the designated area by manual slag removal, and the six-axis robot automatically salvages the scum in the area. The equipment is equipped with a liquid level measuring device, which can automatically adjust the slag fishing trajectory according to the change of the zinc liquid level.

Contact Now

The production line is a flexible automatic production line. By using six-axis robots, 2D vision system, 3D vision system, and servo press, it realizes automatic processing, testing, grinding, and assembly of automotive parts such as main reduction shells and main reduction shell covers for heavy trucks. It is compatible with the automatic production of more than ten kinds of products. The production line has a high degree of flexibility and is the first of its kind in China.ZQJK-2528PLCompatible product size: ≤ 700 mm;Product assembly weight: ≤ 80 kg.

Contact Now

Specification of Reducer housing automatic flexible production line:ModelZQJK-2528PLCompatible product size≤ 700 mmProduct assembly weight≤ 80 kgThe production line is a flexible automatic production line. By using six-axis robots, 2D vision system, 3D vision system, and servo press, it realizes automatic processing, testing, grinding, and assembly of automotive parts such as main reduction shells and main reduction shell covers for heavy trucks. It is compatible with the automatic production of more than ten kinds of products.

Contact Now

Outer Protective Ring Tightening RobotDeviceDescription/Instruction:The inner and outer protective ring screwing robot equipment is the core equipment for petroleum pipe processing with a robot as the carrier in the industry at present, which can significantly improve the screwing performance of the protective ring screwing process. It can be used with the inner and outer automatic oiling equipment and the inner and outer protective ring automatic feeding device to achieve the purpose of unmanned production of the post and effectively reducelabor and operating costs.

Contact Now

Inner Protective Ring Tightening RobotDevice:Description/Instruction: The inner and outer protective ring screwing robot equipment is the core equipment for petroleum pipe processing with a robot as the carrier in the industry at present, which can significantly improve the screwing performance of the protective ring screwing process. It can be used with the inner and outer automatic oiling equipment and the inner and outer protective ring automatic feeding device to achieve the purpose of unmanned production of the post and effectively reduce labor and operating costs.

Contact Now

Desheng Intersecting line cutting robot: ModelDSHJ-XGX01Cutting method laser or plasmaWelding methodfusion weldingPipe diameterφ 80 ~ 350 mm; Large pipe diameter can be customized.The processing of pipe-pipe intersecting lines is widely used in nuclear power equipment, fire pipelines, pressure vessels, oil and gas transportation, water supply and heating, and other industries. The equipment relies on the national 863 project "intersection curve automatic welding CNC equipment technology and application demonstration" undertaken by the center.

Contact Now