Fanuc Mig Welding RobotsFanuc Mig Welding Robots, Fronius Cobot Welding, and Daihen Welding Machines are some of the leading companies in the field of welding robots. These companies have revolutionized the welding industry with their advanced technologies and high-quality products.Fanuc Mig Welding Robots offer precise and efficient welding solutions. Equipped with state-of-the-art sensors and controllers, these robots can handle complex welding tasks with ease.

Contact Now

Fanuc Arc Welding RobotsFanuc Arc Welding Robots, Kemppi Robotic Welding, Fronius Robotic Welding Torch, and Fronius Robot Welding are all advanced technologies used in the field of industrial automation. These tools are designed to improve the efficiency and accuracy of welding processes in manufacturing industries.Fanuc Arc Welding Robots are known for their high precision and speed. They are equipped with state-of-the-art sensors and control systems that enable them to perform complex welding tasks with ease.

Contact Now

Fanuc Crx WeldingThe Fanuc CRX Welding system, Kawasaki Robot Welding, Kuka Arc Welding Robot, and Kuka Friction Welding are all innovative solutions for welding applications. The Fanuc CRX Welding system stands out for its advanced technology, efficient operation, compact design, user-friendly interface, and reliability. The Kawasaki Robot Welding system excels in its flexibility, precision, speed, and versatility. The Kuka Arc Welding Robot offers exceptional performance, durability, and ease of programming.

Contact Now

Robotic Mig Welding Machine: Robotic Mig Welding Machine is engaged in welding (including cutting and spraying) industrial robots. According to the definition of an industrial robot belonging to a standard welding robot adopted by the International Organization for Standardization (ISO), an industrial cobot welding robot is a multi-purpose, reprogrammable automatic control Manipulator with three or more programmable axes for use in the field of industrial automation.

Contact Now

Fanuc Welding RobotFanuc Welding Robot, Lincoln Electric Cobot, Universal Robots Welding, and other welding automation companies are revolutionizing the welding industry. These advanced robots and cobots are equipped with state-of-the-art technology, allowing for precise and efficient welding processes. With their ability to work tirelessly and consistently, they are increasing productivity and reducing human error. These companies are at the forefront of welding automation, constantly pushing the boundaries of what is possible.

Contact Now

Fanuc Tig Welding RobotFanuc Tig Welding Robot is a state-of-the-art robotic Tig welding machine equipped with a robotic Tig welding torch. This advanced technology revolutionizes the welding industry by offering precise and efficient welding solutions.The Fanuc Tig Welding Robot combines the precision and skill of a human welder with the speed and accuracy of a machine. It is programmed to perform complex welding tasks with utmost precision, ensuring high-quality welds every time.The robotic Tig welding machine is equipped with a Tig welding torch that can be controlled remotely.

Contact Now

Fanuc Welding Robot PriceFanuc Welding Robot Price: The price of a Fanuc welding robot can vary depending on the specific model and features required. On average, a basic Fanuc welding robot can cost around $50,000 to $80,000.Fronius Cobot: The Fronius Cobot is a collaborative robot designed for various applications, including welding. The price of a Fronius Cobot can range from $30,000 to $50,000, depending on the specific model and capabilities.Kuka Welding Robot Price: Kuka is a renowned brand in the welding robot industry.

Contact Now

Engineering Design And Analysis:Engineering design and analysis are critical in the production of high-quality, efficient robotics. With these processes, engineers can identify the best materials, control systems, and performance parameters for their machines. One area of application for robots is welding, and this is where laser welding and MIG welding for beginners come in. Laser welding offers precision and speed, making it perfect for delicate applications like aluminium welding. MIG welding is easier to learn and is perfect for beginners.

Contact Now

Otc Daihen Welding RobotThe Otc Daihen Welding Robot, Panasonic Mig Welding Robot, Panasonic Robotic And Welding Equipment, and Panasonic Robotic Welding Machine are all top-notch solutions for welding applications. The Otc Daihen Welding Robot excels in its advanced technology, high-speed performance, excellent welding quality, versatility, user-friendly interface, reliability, and durability. The Panasonic Mig Welding Robot offers precise and efficient welding capabilities, ensuring consistent and high-quality welds.

Contact Now

Panasonic Welding Robot ProgrammingPanasonic Welding Robot Programming offers a user-friendly interface, advanced features, and seamless integration to enhance the programming process. Panasonic Welding Robot Teaching allows for easy and intuitive setup of welding tasks, increasing productivity. When it comes to Robotic Welding Machine manufacturers, Panasonic is a renowned name known for its reliable and efficient solutions. Additionally, Yaskawa Mig Welding Robot offers precise and efficient welding capabilities, ensuring high-quality welds.

Contact Now

Kuka Friction Welding MachineThe Kuka Friction Welding Machine, Kuka Laser Welding, Kuka Mig Welding Robot, and Kuka Spot Welding Robot are all exceptional solutions for welding applications. The Kuka Friction Welding Machine stands out with its ability to join different materials, reducing costs and providing high-quality welds. Kuka Laser Welding offers precise and efficient welding capabilities, especially for delicate and complex components. The Kuka Mig Welding Robot excels in its versatility, speed, and reliability, making it suitable for a wide range of welding tasks.

Contact Now

Robots Welding Cars:Robots welding cars, such as those used in BMW manufacturing plants, offer numerous advantages in the automotive industry. Firstly, they provide precise and consistent welds, ensuring high-quality and reliable joints. Secondly, comparing KRC2 vs KRC4 controllers, the latter offers advanced features like improved motion control and programming capabilities, enhancing overall performance. Additionally, robotic arm grippers allow for flexibility in picking up and manipulating car parts, optimizing the assembly process.

Contact Now

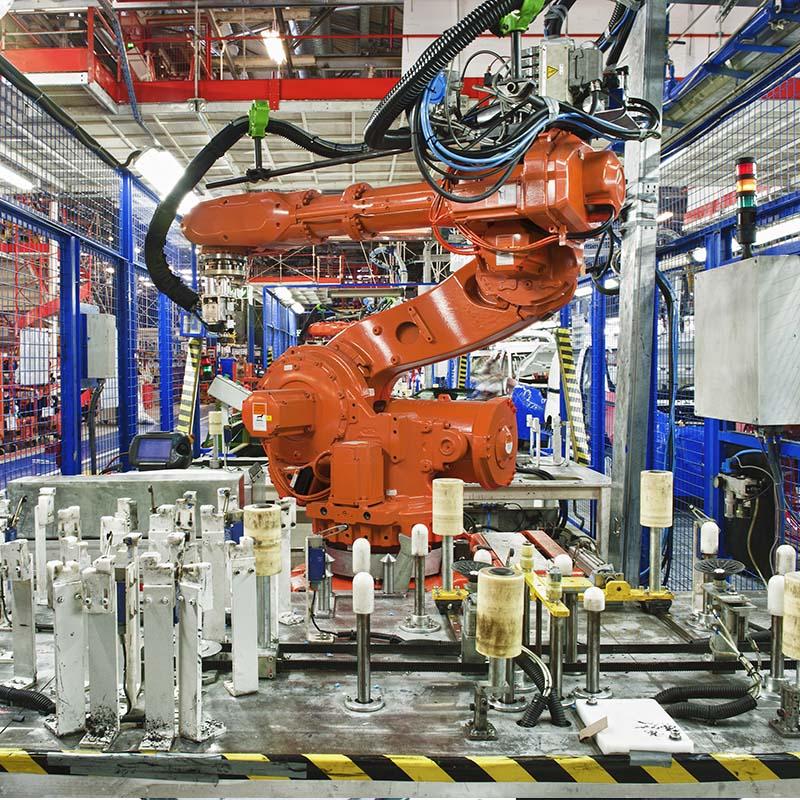

Abb Welding Robots Company:Abb Welding Robots Company and Kuka Welding Robot are two well-known manufacturers of 6-axis robots. These robots have revolutionized the welding industry with their precision and efficiency.Abb Welding Robots Company has been a leader in the robotics industry for many years. Their welding robots are known for their high-quality construction and advanced technology. These robots are capable of performing complex welding tasks with ease, making them a popular choice among manufacturers.Kuka Welding Robot is another prominent player in the market.

Contact Now

Welding robot manufacturers worldwide are producing welding robots that are becoming increasingly popular in industries that require precision, speed, and safety in welding operations. There are various types of welding robots available on the market, including articulated robots, cartesian robots, and SCARA robots. These welding robots are manufactured using advanced techniques and technologies to meet specific customer requirements. The most commonly used type of welding robot is the robotic welding arm, which offers the flexibility and versatility needed in welding applications.

Contact Now

Fanuc SCARA Robot Solutions:Fanuc SCARA Robot Solutions, offered by Automated Technologies Inc., play a crucial role in machine tool automation and precision automation systems. These advanced robotic solutions are designed to provide high-speed and precise performance in various industries. With easy integration and programming capabilities, Fanuc SCARA robots can seamlessly integrate into existing production lines. This not only enhances efficiency and accuracy but also ensures continuous productivity.

Contact Now

Welding Using Robotic Arm:Welding using robotic arms has gained popularity in various industries. Robot Kuka Mexico and Fanuc Laser Robot are leading providers of advanced robotic systems for welding applications. These robots offer precise and efficient welding capabilities, delivering high-quality welds consistently.Additionally, pick and place robots play a vital role in the welding process by handling and positioning the workpieces accurately, ensuring seamless welding operations.

Contact Now

Robots For Car Body Welding:Robots for car body welding, such as the Kuka KRC2, offer numerous advantages in terms of precision, efficiency, and safety. These robots ensure consistent weld quality with minimal errors due to their high accuracy. They can work tirelessly without fatigue, resulting in increased productivity and reduced cycle time compared to manual welding. Moreover, using robots for welding tasks enhances the safety of workers by minimizing their exposure to harmful fumes, sparks, and heat.

Contact Now

Automated Welding Robots For CarsAutomated welding robots have revolutionized the car manufacturing industry. Companies like Yaskawa and Kawasaki have developed advanced robot welding systems that are widely used in car production.Yaskawa's robot welding technology ensures precise and efficient welding of car components. With their high-speed and accurate movements, these robots can weld various parts of a car, including the chassis, body panels, and exhaust systems.

Contact Now

Seiko Epson Robots:Seiko Epson Robots, Seaveon Robotics and Automation, Fanuc Factory Automation, and Autonomous Robots Industry are all prominent players in the field of robotics and automation. These companies specialize in developing advanced robotic systems that are capable of performing various tasks with precision and efficiency.Seiko Epson Robots, a subsidiary of the renowned Seiko Epson Corporation, is known for its cutting-edge robotic solutions.

Contact Now

Welding Robots Car Assembly:Welding Robots in car assembly, powered by the Kuka Krc5 Controller, have revolutionized the manufacturing industry. Equipped with a manipulator robot arm, these robots offer numerous advantages. They provide fast and efficient production rates, ensuring increased productivity. With precise programming and advanced sensors, they deliver accurate and consistent welding, resulting in high-quality welds. In addition, these automation solutions ensure worker safety by eliminating the risks associated with manual welding.

Contact Now

Advanced Efficient Energy Robotics:Advanced Efficient Energy Robotics is a cutting-edge technology that is revolutionizing the manufacturing industry. They are highly efficient, precise, and energy-saving robots that use intelligent energy-saving technology to reduce energy consumption and promote a sustainable environment.To fully leverage the capabilities of Advanced Efficient Energy Robotics, welding professionals rely on superior products like Everyday Welding Supplies, Miller 350p Manual, and Best 110v Mig Welder.

Contact Now

Hospitality Robots SolutionHospitality Robots Solution, Used Fanuc Robots For Sale, Handling Robot Solution, and Aerospace Robots Solution offer various advantages in their respective fields.Hospitality Robots Solution enhances guest experiences by providing personalized interactions, quick room service, and efficient concierge services.Used Fanuc Robots For Sale provide cost-effective automation solutions for industries, optimizing productivity and reducing labor costs.Handling Robot Solution brings efficiency to material handling tasks, improving workflow and ensuring accurate and timely del

Contact Now

Autonomous Construction Robots:Autonomous construction robots, such as the Kuka Kr Cybertech and robots offered by pick and place robot manufacturers like Fanuc Material Handling Robots, bring numerous advantages to the construction industry. These robots are designed to handle hazardous and repetitive tasks, ensuring the safety of human workers. With their advanced technology and precision, they enhance efficiency and productivity on construction sites. Additionally, autonomous construction robots can navigate complex terrains and environments, adapting to various conditions.

Contact Now

Lincoln Electric Robotic WelderLincoln Electric Robotic Welder, Valk Welding Robot Panasonic, Panasonic Welding Robot Price, and Welding Robot Fanuc are all advanced robotic welding equipment. These robots have revolutionized the welding industry by offering precision, efficiency, and productivity.The Lincoln Electric Robotic Welder is known for its exceptional welding performance. It is highly versatile and capable of handling various welding tasks.

Contact Now