The automatic oiling device for the external thread of the steel pipe is characterized in that the thread oil is conveyed into a spray gun through a servo quantitative oil filling pump system, and the spray gun atomizes and sprays the thread oil on the external thread of the steel pipe with the help of compressed air, so that the amount of grease can be automatically matched according to the specification of a steel pipe, and the amount of grease is greatly saved.

Contact Now

External OilingDevice Description/Instruction: The automatic oiling device for the external thread of the steel pipe is characterized in that the thread oil is conveyed into a spray gun through a servo quantitative oil filling pump system, and the spray gun atomizes and sprays the thread oil on the external thread of the steel pipe with the help of compressed air, so that the amount of grease can be automatically matched according to the specification of a steel pipe, and the amount of grease is greatly saved.

Contact Now

External Water BlowingThe special air knife technology is used to make the compressed air evenly and annularly spray on the surface of the steel pipe thread, so as to blow off the emulsion and scrap iron on the surface of the internal or external thread, and it is equipped with a waste water recovery device.

Contact Now

The automatic oiling device for the internal thread of the steel pipe is characterized in that thread oil is conveyed into an oiling head through a servo quantitative oil filling pump system, and the oiling head rotates at a high speed to atomize and spray the thread oil on the internal thread of a matching coupling of the steel pipe. It can automatically match the amount of grease according to the specifications of steel pipes, which greatly saves the amount of grease.

Contact Now

In the off-line oiling device, the thread oil is delivered to the oiling head through the oil filling pump, and the oiling head rotates at a high speed to atomize and spray the thread oil on the internal thread of the matching coupling.DSTY-7/13/20L"Coupling specification: 7 ""/13""/20 "";Maximum speed of oiling head: 6000rpm."

Contact Now

Internal OilingDevice Description/ Instruction:The automatic oiling device for the internal thread of the steel pipe is characterized in that thread oil is conveyed into an oiling head through a servo quantitative oil filling pump system, and the oiling head rotates at a high speed to atomize and spray the thread oil on the internal thread of a matching coupling of the steel pipe. It can automatically match the amount of grease according to the specifications of steel pipes, which greatly saves the amount of grease.

Contact Now

Coupling Offline OilingIn the off-line oiling device, the thread oil is delivered to the oiling head through the oil filling pump, and the oiling head rotates at a high speed to atomize and spray the thread oil on the internal thread of the matching coupling.

Contact Now

The unique air knife generation is used to make the compressed air frivolously and annularly spray at the floor of the metallic pipe thread, with a view to blow off the emulsion and scrap iron at the floor of the inner or outside thread, and it's far ready with a waste water restoration device.DSCS-7/13/20WSteel pipe specification: 7 ""/13 ""/20 ""

Contact Now

Internal Water BlowingThe special air knife technology is used to make the compressed air evenly and annularly spray on the surface of the steel pipe thread, so as to blow off the emulsion and scrap iron on the surface of the internal or external thread, and it is equipped with a waste water recovery device.

Contact Now

The robotic Protector Applier The Robotic Protector Applier system serves as the pivotal equipment in the octg Pipe industry with a robot as its carrier, significantly enhancing the screwing performance of the protection ring installation process. The pipe Protector Applier system seamlessly collaborates with both internal and external automatic oiling equipment, as well as automated loading and unloading devices for internal and external protector Applier, thereby achieving unmanned production capabilities while effectively reducing labor and operational costs.

Contact Now

The special air knife technology is used to make the compressed air evenly and annularly spray on the surface of the steel pipe thread, so as to blow off the emulsion and scrap iron on the surface of the internal or external thread, and it is equipped with a waste water recovery device.DSCS-7/13/20NSteel pipe specification: 7 ""/13 ""/20 ""

Contact Now

The coupling pre-tightening robot grasps the coupling after off-line oiling and completes the pre-tightening of the coupling according to a preset program.

Contact Now

The inner and outer protecting ring screwing robotic system is the middle system for petroleum pipe processing with a robotic because the service withinside the enterprise at present, that could substantially enhance the screwing overall performance of the protecting ring screwing process. It may be used with the internal and outer computerized oiling system and the internal and outer protecting ring computerized feeding tool to obtain the reason of unmanned manufacturing of the put up and successfully lessen hard work and running costs.

Contact Now

The coupling pre-tightening robot grasps the coupling after off-line oiling and completes the pre-tightening of the coupling according to a preset program. The coupling pre-tightening robot can effectively control the coupling pre-tightening parameters and can realize the functions of automatic measurement, automatic recording, storage, data uploading, and the like of the J value through the combined control with the screwing.

Contact Now

Outer Protective Ring Tightening RobotDeviceDescription/Instruction:The inner and outer protective ring screwing robot equipment is the core equipment for petroleum pipe processing with a robot as the carrier in the industry at present, which can significantly improve the screwing performance of the protective ring screwing process. It can be used with the inner and outer automatic oiling equipment and the inner and outer protective ring automatic feeding device to achieve the purpose of unmanned production of the post and effectively reducelabor and operating costs.

Contact Now

Inner Protective Ring Tightening RobotDevice:Description/Instruction: The inner and outer protective ring screwing robot equipment is the core equipment for petroleum pipe processing with a robot as the carrier in the industry at present, which can significantly improve the screwing performance of the protective ring screwing process. It can be used with the inner and outer automatic oiling equipment and the inner and outer protective ring automatic feeding device to achieve the purpose of unmanned production of the post and effectively reduce labor and operating costs.

Contact Now

Coupling Pre-Tightening RobotThe coupling pre-tightening robot grasps the coupling after off-line oiling and completes the pre-tightening of the coupling according to a preset program. The coupling pre-tightening robot can effectively control the coupling pre-tightening parameters and can realize the functions of automatic measurement, automatic recording, storage, data uploading, and the like of the J value through the combined control with the screwing. It completely realizes the conversion of this robot to replace manual labor and achieves unmanned production.

Contact Now

OCTG Coupling Starter systemThe OCTG Coupling Starter system facilitates the secure gripping of the Coupling by the robot, allowing for offline oiling and executing pre-twisting of the Coupling according to a predetermined program.This Robotic Coupling Starter effectively regulates pre-screwing parameters, enabling integration with screwing control to achieve automatic J-value measurement, automated recording and storage, data upload, and other functionalities.It fully realizes the substitution of manual labor with robotic automation, enabling unmanned production.

Contact Now

Automatic black leather buckle removing and grinding equipmentPayment type:L/C, T/TIncoterm:FOB QingdaoMin. order: 1 setDelivery time : 30-50 working daysWarranty : 1 yearAfter-service: 24 hours online Rotary grinding is adopted to automatically position the pipe end, realize the positioning of the threaded pipe end and the grinding of the black leather buckle according to different specifications, and automatically recycle the scrap iron and dust generated by grinding.

Contact Now

Material Handling RobotsMaterial handling robots are becoming increasingly popular in industries that require efficient and precise movement of objects. These robots are equipped with advanced sensors and algorithms that allow them to pick up and place objects with great accuracy.Pick and place robots, on the other hand, are specifically designed for tasks that involve picking up an object from one location and placing it in another.

Contact Now

Warehouse Logistics RobotsWarehouse Logistics Robots, such as Epson Industrial Robots, offered by Hi Tech Robotics Systems Ltd, are a cost-effective investment for businesses. These robots, including those from Abb Robot Cost, offer numerous advantages. They enhance efficiency by automating repetitive tasks, enabling workers to focus on more complex activities. With their precise algorithms, these robots improve accuracy and reliability, ensuring that inventory management is optimized. Moreover, they increase worker safety by reducing the risk of accidents.

Contact Now

Spot Weld Robot Operation:The KUKA KR 300 R2700 is a spot weld robot used in various industries, including entertainment. This KUKA arm robot is equipped with advanced technology and precision to perform spot welding operations with ease.In the entertainment industry, robots like the KUKA KR 300 R2700 are used for special effects, creating stunning visuals, and enhancing live performances.

Contact Now

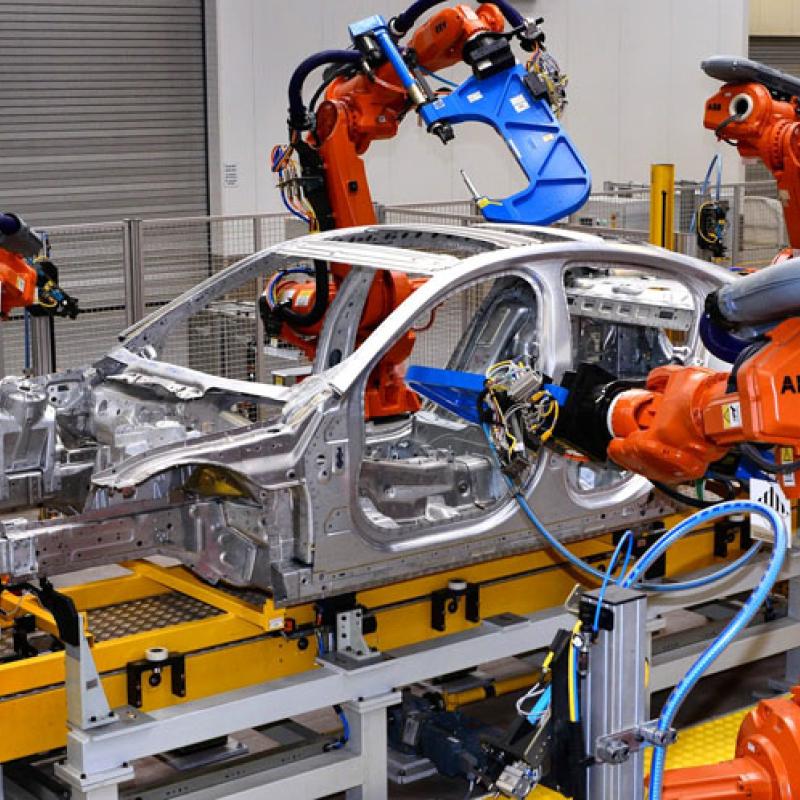

Robot Technology In Car Manufacturing Solution:Robot technology has played a crucial role in revolutionizing car manufacturing. China, being one of the largest automobile manufacturers, is at the forefront of utilizing robots in their car factories. These robots are used in various aspects of the manufacturing process, from assembling car parts to quality control. By incorporating robots in car factories, production efficiency has significantly increased, allowing for shorter lead times and cost savings.

Contact Now