Electronics Pick And Place Robot:In the realm of industrial automation, the Electronics Pick and Place Robot has emerged as a game-changer. Its capability to precisely handle electronic components has revolutionized the electronics manufacturing industry.The Electronics Pick and Place Robot is part of the broader domain of industrial robots, which encompasses a wide range of robotic systems used in various sectors. As the demand for automation grows, so does the number of industrial robot manufacturers.

Contact Now

Delta Electronics Robot:Delta Electronics is a leading manufacturer of industrial robots, specializing in cobots for Industry 4.0. Their robots are designed to work collaboratively with humans, enhancing productivity and safety in the workplace. With advanced technology and innovative features, Delta Electronics robots are revolutionizing the manufacturing industry.Mobile Industrial Robots (MiR) is another prominent player in the robotics industry. They specialize in autonomous mobile robots that can navigate through industrial environments, transporting materials and goods efficiently.

Contact Now

Automated Electronics Assembly Line:Automated Electronics Assembly Lines have revolutionized the manufacturing industry by providing numerous benefits that increase efficiency, accuracy, and cost savings. These assembly lines are crucial for the production of electronics, automobiles, and other complex products.Auto Assembly Line Ford, Auto Factory Assembly Line, and Automatic Production Line Machine Hs Code are some of the most advanced and widely used Automated Electronics Assembly Lines in the industry.

Contact Now

Advanced Robot Control Electronics:The implementation of Advanced Robot Control Electronics has become increasingly important in the Automobile Manufacturing Industry. LS Automotive Technologies is embracing this trend with open arms, utilizing advanced robot control electronics to improve production efficiency, reduce costs and accelerate the development cycles for new models and technologies.

Contact Now

Robots In Electronics Industry:Robots in the electronics industry have revolutionized the production process. Companies like Kuka have introduced advanced robots such as the Kuka KR Agilus and Kuka Servo Robot, along with robotic handling systems. These innovations offer numerous benefits. The Agilus provides high speed and precision, enabling efficient manufacturing. Meanwhile, the Servo Robot ensures consistent quality control, reducing defects. Additionally, robotic handling systems improve workplace safety by handling delicate and hazardous materials.

Contact Now

This assembly line is a versatile automated manufacturing line, which realizes the automated meeting of steerage knuckle meeting for heavy vehicles via way of means of the usage of a six-axis robot, 2D imaginative and prescient system, 3-D imaginative and prescient system, and servo press. It is well suited with the automated manufacturing of greater than twenty varieties of guidance knuckle products. There isn't anyt any guide operation role withinside the line, that could meet the manufacturing of the unique shape guidance knuckle and different vehiclemobile parts.

Contact Now

Articulated Robot Applications:Articulated Robot Applications offer numerous advantages in various industries. The KUKA KR 30 R2100 is a notable example of an articulated robot that excels in precision and versatility. Its multiple joints and high accuracy make it ideal for tasks in automotive manufacturing and electronics assembly. Another noteworthy robot is the BCN3D Moveo Robot, known for its open-source nature and educational value. It allows users to learn and experiment with robotics while improving their technical skills.

Contact Now

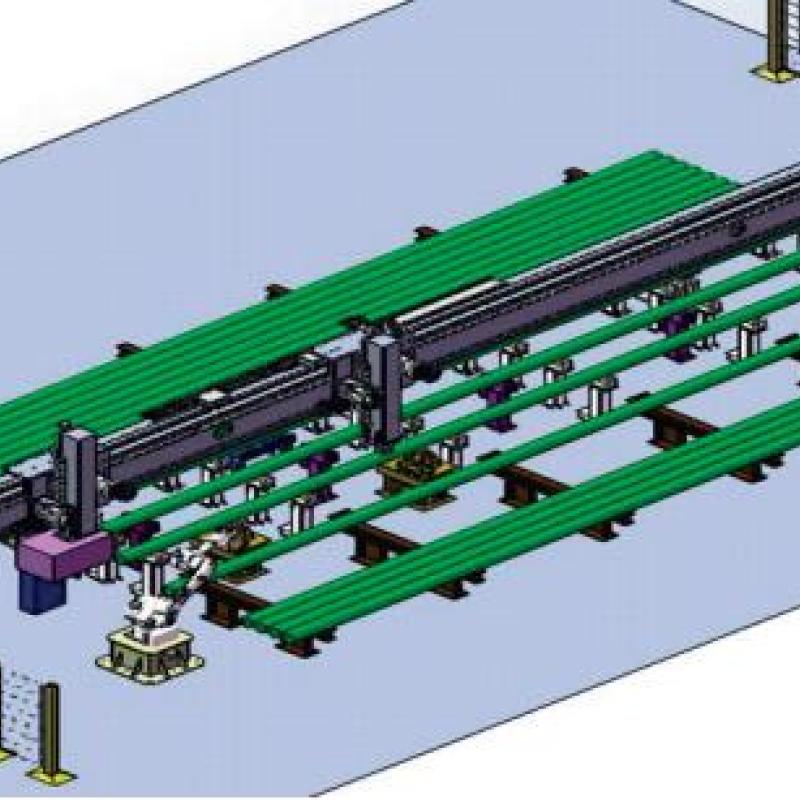

This assembly line is a flexible automatic production line, which realizes the automatic assembly of steering knuckle assembly for heavy trucks by using a six-axis robot, 2D vision system, 3D vision system, and servo press. It is compatible with the automatic production of more than twenty kinds of steering knuckle products. There is no manual operation position in the line, which can meet the production of the special structure steering knuckle and other auto parts.

Contact Now

This assembly line is a flexible automatic production line, which realizes automatic assembly of V-type thrust rod assemblies for heavy trucks by using six-axis robots, 2D vision systems, 3D vision systems, and servo presses. It is compatible with the automated production of many kinds of V-type thrust rod and other auto parts assembly products. The line is equipped with manual operation positions to meet the production of special structure thrust rod assemblies.

Contact Now

It is a fully automatic flexible assembly line, which can complete automatic assembly of axle holes with very small fit gaps by using six-axis robots, 2D vision system, and 3D vision system, and is compatible with a wide range of specifications. This production line is the first of its kind in the world to achieve fully automatic flexible assembly of automotive parts such as differentials for heavy trucks.DSCS-375ALProduct assembly weight: ≤ 80 kg;Assembly clearance of shaft hole: ≥ 0.02mm.

Contact Now

The assembly line is a flexible automatic production line. Tie Rod Assembly Line Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.By using six-axis robots, 2D vision system, 3D vision system, and servo tightening machine, it realizes automatic buckle clearing, coding, clamping, and assembly of auto parts such as cross ties for heavy trucks. It is compatible with the automatic production of more than ten kinds of products.

Contact Now

Unimate Robot Automation Assembly:Unimate Robot Automation Assembly, Stick Shielded Metal Arc Welding, ASME Section 9 Brazing Procedures, and Victor Welding Cutting Torches are all important tools and processes used in modern manufacturing and fabrication. The Unimate Robot Automation Assembly is a versatile tool that can help streamline the manufacturing process, resulting in higher efficiency and better product quality.

Contact Now

Robot Car Assembly Line:The use of robot car assembly lines in car manufacturing has numerous advantages. Robots ensure precision and accuracy, resulting in high-quality vehicles. They work faster than humans, increasing productivity. Moreover, robots work consistently without fatigue or distractions, improving efficiency. They also take over dangerous tasks, enhancing worker safety. A video showcasing a robot car assembly line displays the precise movements and speed of the robots.

Contact Now

Ansi Ria r15 06 2012:The ANSI RIA R15.06-2012 standard, along with the Delta Industrial Automation technology, plays a vital role in the field of Electronics and Automation, particularly in Industrial Automation Design. This standard ensures increased safety measures, enhances productivity, and simplifies implementation. With Delta Industrial Automation's cutting-edge technology, companies can seamlessly integrate robotic systems into their operations, optimizing efficiency and production.

Contact Now

Wall Painting Robot Arduino:The Wall Painting Robot Arduino is a revolutionary device that can turn any plain wall into a beautiful piece of art. With its precise movements and programming capabilities, it can create intricate designs and patterns with ease. The robot arm, UR5, is known for its versatility and high precision. It is widely used in various industries such as automotive, electronics, and food processing. The price of UR5 robot arm may vary depending on the configuration and additional accessories.

Contact Now

Automotive Assembly Line Robots:Automotive assembly line robots are revolutionizing the automobile industry by providing several benefits. These robots perform tasks with precision and speed, resulting in increased efficiency and productivity.

Contact Now

Automotive Assembly Line Robots:Automotive assembly line robots, such as the Air Skin Kuka, offer several advantages in terms of efficiency, precision, and safety. These robots are capable of working tirelessly without fatigue, ensuring continuous production and increased productivity on the assembly line. With their high accuracy and consistent movements, they contribute to improved product quality and reduced errors in assembly tasks.The Air Skin Kuka is a remarkable example of a 6-axis robot arm that can be utilized for various automotive assembly applications.

Contact Now

Abb Collaborative RobotABB Collaborative Robot, Process Automation Robotics, KUKA KR 16, and KUKA KR C4 are efficient and advanced solutions in the field of automation.ABB Collaborative Robot offers safe collaboration with human workers, streamlining processes in industries such as manufacturing and logistics.Process Automation Robotics optimizes workflow efficiency by automating repetitive tasks with high precision and reliability, boosting productivity.KUKA KR 16 is a versatile and agile robot, capable of handling various applications in industries like automotive and electronics manufacturi

Contact Now

3m Carbon Packing Tape Robot:The 3M Carbon Packing Tape Robot is a cutting-edge robotic device that offers several advantages in the industry. With its advanced carbon fiber construction and combat robot electronics, it is designed to withstand tough environments and impacts and ensure maximum uptime for production lines. Additionally, the robot is equipped with advanced construction robotics technology that allows it to operate with enhanced agility and precision, enabling it to perform tasks that would be challenging for human workers.

Contact Now

Fully Automated Assembly Line:Fully automated assembly lines have become increasingly popular in modern manufacturing facilities due to their numerous advantages. An auto assembly line is a prime example of such a mechanism, allowing for the completion of a large number of tasks through reduced manual operations and increased automation, hence improving its consistency and quality output. Auto assembly plants across the world, such as the Auto Assembly Plant Mexico, have been embracing this technology in efforts to optimize their respective manufacturing processes.

Contact Now

Autonomous Mobile Robot ManufacturersAutonomous Mobile Robot Manufacturers, such as Kuka and ABB Robotics Webshop, offer a range of advanced robotic arms for various industries. Kuka Small Robot Arm is known for its compact size and versatility, making it perfect for smaller workspaces. These robots are widely used in the electronics industry for tasks such as pick-and-place operations. With their precise movements and high-speed capabilities, they increase efficiency and productivity.

Contact Now

Automated Automotive Assembly Line:An automated automotive assembly line, equipped with machines and robotics, ensures accurate, reliable, and efficient production of automobiles by reducing manual labor. Auto Assembly Line Photos show how machines work tirelessly, achieving a higher output rate in a shorter time frame without breaks. Automated Assembly Line Definition highlights the built-in quality control measures to ensure every product is made to the highest standards.

Contact Now

Construction Robot SolutionConstruction Robot Solution, such as Kuka Robot Price, Meca500 Solution, and Robot Electronics Solution, has revolutionized the construction industry. With the help of these advanced robotic technologies, construction projects are completed faster, safer, and more cost-effectively. Kuka Robot Price offers highly efficient and precise programming that reduces the need for manual labor. Meca500 Solution brings versatility and agility to construction tasks, increasing productivity.

Contact Now

Automated Car Assembly Line:Automated Car Assembly Line, Kuka Youbot Arm, Abb Yumi Robot Manual, and Joseph Engelberger Robots are significant advancements in industrial robotics. The assembly line streamlines car manufacturing, reducing costs and improving efficiency. The Kuka Youbot Arm performs various tasks with precision. Abb Yumi Robot Manual enhances productivity and safety through collaboration. Joseph Engelberger Robots honor a pioneer in robotics, shaping the future of automation. These innovations continue to revolutionize industries, boosting productivity and driving progress.

Contact Now