External Water BlowingThe special air knife technology is used to make the compressed air evenly and annularly spray on the surface of the steel pipe thread, so as to blow off the emulsion and scrap iron on the surface of the internal or external thread, and it is equipped with a waste water recovery device.

Contact Now

Internal Water BlowingThe special air knife technology is used to make the compressed air evenly and annularly spray on the surface of the steel pipe thread, so as to blow off the emulsion and scrap iron on the surface of the internal or external thread, and it is equipped with a waste water recovery device.

Contact Now

The special air knife technology is used to make the compressed air evenly and annularly spray on the surface of the steel pipe thread, so as to blow off the emulsion and scrap iron on the surface of the internal or external thread, and it is equipped with a waste water recovery device.DSCS-7/13/20NSteel pipe specification: 7 ""/13 ""/20 ""

Contact Now

The unique air knife generation is used to make the compressed air frivolously and annularly spray at the floor of the metallic pipe thread, with a view to blow off the emulsion and scrap iron at the floor of the inner or outside thread, and it's far ready with a waste water restoration device.DSCS-7/13/20WSteel pipe specification: 7 ""/13 ""/20 ""

Contact Now

The automatic oiling device for the external thread of the steel pipe is characterized in that the thread oil is conveyed into a spray gun through a servo quantitative oil filling pump system, and the spray gun atomizes and sprays the thread oil on the external thread of the steel pipe with the help of compressed air, so that the amount of grease can be automatically matched according to the specification of a steel pipe, and the amount of grease is greatly saved.

Contact Now

Coupling Finishing Machine1. Steel pipe is clamped with a double-chuck shape, and the pneumatic chuck adopts an imported big-diameter chuck. the clamping and loosening of the chuck can most effective be performed while the spindle stops. under the movement of the air manage take a look at valve, the air pressure inside the clamping cylinder stays unchanged and the movement is reliable.2. Hydraulic servo tool holder adopts the device holder imported from italy, with speedy and solid indexing, no lifting mechanism, massive diameter toothed disc, excessive precision and large locking pressure.3.

Contact Now

JMT series pipe threading machine1. The steel pipe is clamped with a double-chuck structure, and the pneumatic chuck adopts an imported large-diameter chuck. The clamping and loosening of the chuck can only be performed when the spindle stops. Under the action of the air control check valve, the air pressure in the clamping cylinder remains unchanged and the action is reliable.2. The hydraulic servo tool holder adopts the tool holder imported from Italy, with fast and stable indexing, no lifting mechanism, large diameter toothed disc, high precision and large locking force.3.

Contact Now

External OilingDevice Description/Instruction: The automatic oiling device for the external thread of the steel pipe is characterized in that the thread oil is conveyed into a spray gun through a servo quantitative oil filling pump system, and the spray gun atomizes and sprays the thread oil on the external thread of the steel pipe with the help of compressed air, so that the amount of grease can be automatically matched according to the specification of a steel pipe, and the amount of grease is greatly saved.

Contact Now

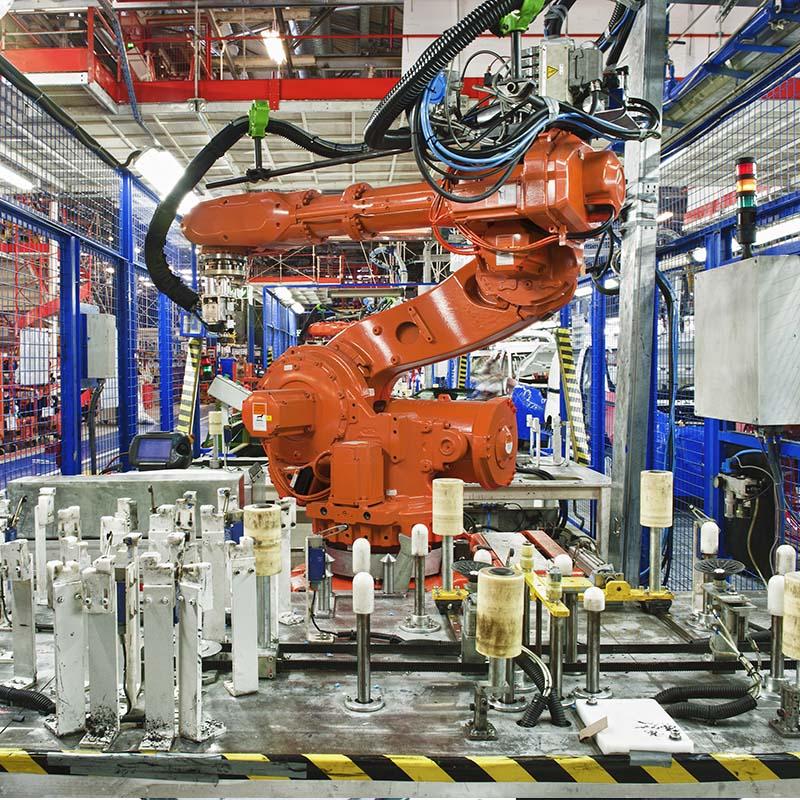

Automotive Assembly Line Robots:Automotive assembly line robots, such as the Air Skin Kuka, offer several advantages in terms of efficiency, precision, and safety. These robots are capable of working tirelessly without fatigue, ensuring continuous production and increased productivity on the assembly line. With their high accuracy and consistent movements, they contribute to improved product quality and reduced errors in assembly tasks.The Air Skin Kuka is a remarkable example of a 6-axis robot arm that can be utilized for various automotive assembly applications.

Contact Now

Large Format Laser Cutting Machine We independent research and development design, H1230 adopts a "double straight" air duct structure, 24 dust removal ports, the first Unique double operation control screen, the main body adopts a bridge design, It solves customer's cutting accuracy and speed, and dusk removal problem.

Contact Now

Structural Design Engineer Aerospace:The field of aerospace design requires skilled professionals who understand the nuances of structural design. That's why having a Structural Design Engineer Aerospace is essential for businesses looking to take on projects in this field. They can help ensure that designs are optimized for safety and efficiency.But having a good design is only half the battle. Welding is also an important part of aerospace manufacturing. Finding Welding Shops Near Me that specialize in aerospace welding can be critical in producing high-quality final products.

Contact Now

For welding products, you can use a collaborative robot to automate a welding application quickly and easily.By connecting a welding torch to the robot and then having it move along the desired path, accurately laid welds are created. The cobot always moves at the desired speed and is accurate to within 0.1mm. In this way the cobot ensures consistent, high quality end products. Compared to a standard robot cell, the cobot offers a number of advantages.

Contact Now

This assembly line is a versatile automated manufacturing line, which realizes the automated meeting of steerage knuckle meeting for heavy vehicles via way of means of the usage of a six-axis robot, 2D imaginative and prescient system, 3-D imaginative and prescient system, and servo press. It is well suited with the automated manufacturing of greater than twenty varieties of guidance knuckle products. There isn't anyt any guide operation role withinside the line, that could meet the manufacturing of the unique shape guidance knuckle and different vehiclemobile parts.

Contact Now

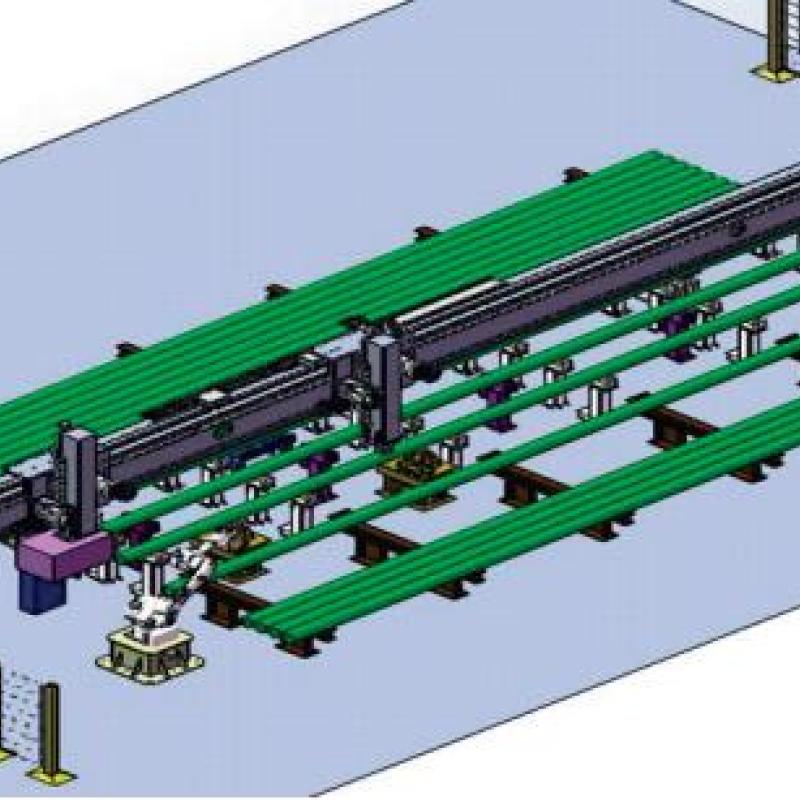

Desheng Inner protective ring tightening robot:This products are mainly equipment in the field of pipe processing, mainly including intelligent processing equipment for casing lines, intelligent processing equipment for optical pipes and intelligent processing equipment for coupling lines.Specification of Inner protective ring tightening robot:Model:protective ring7 "/13"/20 "Maximum screwing torque200/400NMNumber of jaws5/6Screw connection formfloating screw connectionClamping mode of protective ringexternal clamp or internal supportScrew connection distance tolerance

Contact Now

Desheng 3D Disordered Grabing/Grinding robotPayment type:L/C, T/TIncoterm:FOB QingdaoMin. order: 1 setDelivery time : 30-50 working daysWarranty : 1 yearAfter-service: 24 hours online In view of the irregular scene of incoming materials, the 3D vision system can be used to grasp the chaotic materials in disorder, and then realize the high-precision loading and unloading processing of products through automatic centering. After grasping, the system can support the machining center, loading and unloading, grinding, welding, spraying, fixed-point handling, and other

Contact Now

The system is mainly used in the field of metallurgical steel coil products, and it is used to tape and label the coil after winding. Based on the labeling robot, the function is optimized, and the function of sticking tape is integrated. Added tape fixed-length cutting device, tape special suction cup, pressure roller, tape tail detection, and other functions.DSBD-NJ02Coil diameter: φ800 ~ φ2100mm;Steel coil width: 800 ~ 1650mm;Labeling position: inner ring and outer ring;Adhesive tape position: tape tail;Label size: 100mm × 200mm.

Contact Now

Robot For Modern Industry:In the modern industrial landscape, the integration of cutting-edge technologies is revolutionizing the way businesses operate and manufacture products. One such technology is the Robot For Modern Industry, which offers several advantages. These robots offer increased productivity through their ability to work tirelessly without fatigue, completing repetitive tasks with precision and speed.Another notable development is the Mecademic Robot Cost.

Contact Now

This assembly line is a flexible automatic production line, which realizes automatic assembly of V-type thrust rod assemblies for heavy trucks by using six-axis robots, 2D vision systems, 3D vision systems, and servo presses. It is compatible with the automated production of many kinds of V-type thrust rod and other auto parts assembly products. The line is equipped with manual operation positions to meet the production of special structure thrust rod assemblies.

Contact Now

Multiple dual-arm robot systems simulate manual labor to realize the whole process of automatic box opening, box filling, sealing, case opening, box packing, sealing, marking printing, palletizing, etc. The packaging process does not require manual intervention. The products to be packed and the packing cartons are automatically sent out through the system, and the packing operation is carried out according to the set quantity and order.DSBZ-ZX02Multiple dual-arm robot

Contact Now

This assembly line is a flexible automatic production line, which realizes the automatic assembly of steering knuckle assembly for heavy trucks by using a six-axis robot, 2D vision system, 3D vision system, and servo press. It is compatible with the automatic production of more than twenty kinds of steering knuckle products. There is no manual operation position in the line, which can meet the production of the special structure steering knuckle and other auto parts.

Contact Now

The production line is a flexible automatic production line. By using 2D vision to identify the type of workpiece, six-axis robot to automatically grasp the loading, 3D vision to detect dimensional errors, and six-axis robot palletizing, the overall automation of automatic processing, automatic inspection, and automatic palletizing of automotive parts such as axle housings are realized. It is compatible with a variety of bridge shell products.

Contact Now

Specification of Reducer housing automatic flexible production line:ModelZQJK-2528PLCompatible product size≤ 700 mmProduct assembly weight≤ 80 kgThe production line is a flexible automatic production line. By using six-axis robots, 2D vision system, 3D vision system, and servo press, it realizes automatic processing, testing, grinding, and assembly of automotive parts such as main reduction shells and main reduction shell covers for heavy trucks. It is compatible with the automatic production of more than ten kinds of products.

Contact Now

The production line is a flexible automatic production line. By using six-axis robots, 2D vision system, 3D vision system, and servo press, it realizes automatic processing, testing, grinding, and assembly of automotive parts such as main reduction shells and main reduction shell covers for heavy trucks. It is compatible with the automatic production of more than ten kinds of products. The production line has a high degree of flexibility and is the first of its kind in China.ZQJK-2528PLCompatible product size: ≤ 700 mm;Product assembly weight: ≤ 80 kg.

Contact Now

The assembly line is a flexible automatic production line. Tie Rod Assembly Line Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.By using six-axis robots, 2D vision system, 3D vision system, and servo tightening machine, it realizes automatic buckle clearing, coding, clamping, and assembly of auto parts such as cross ties for heavy trucks. It is compatible with the automatic production of more than ten kinds of products.

Contact Now