Robot Painting Cars:Robot painting cars has become a common practice in the automotive industry. With advanced robotic systems, the process has become more efficient and precise. Kuka AG Annual Report 2022 provides insights into the performance and achievements of Kuka AG, a leading robotics company involved in automotive applications. Additionally, Cachorro Quente UR5 refers to the use of UR5, a collaborative robot, in hot dog preparation. This showcases the versatility of robots in various industries.

Contact Now

Automatic Painting RobotThe International Federation of Robotics (IFR) is a global organization that promotes the use of automation in various industries. One of the leading companies in this field is SLK Automation, which specializes in the development and production of automatic painting robots. These robots are designed by Kuka Manufacturing, a renowned manufacturer of industrial robots.With the help of automatic painting robots, industries can achieve higher productivity and efficiency in their painting processes.

Contact Now

Line Painting RobotLine Painting Robot revolutionizes road marking with its precise automation. Similarly, robotic packaging machinery streamlines packaging processes, improving efficiency. Fleximech Automation's solutions enhance productivity in various industries. Tesla's manufacturing robots have transformed the automotive sector with their advanced capabilities. Collectively, these technologies exemplify the power of automation in driving innovation and cost-effectiveness. From road safety to packaging efficiency, industrial automation continues to redefine industries.

Contact Now

Wall Painting Robot Arduino:The Wall Painting Robot Arduino is a revolutionary device that can turn any plain wall into a beautiful piece of art. With its precise movements and programming capabilities, it can create intricate designs and patterns with ease. The robot arm, UR5, is known for its versatility and high precision. It is widely used in various industries such as automotive, electronics, and food processing. The price of UR5 robot arm may vary depending on the configuration and additional accessories.

Contact Now

Robots In Medical FieldRobots have revolutionized various industries, including the medical field. In recent years, robots have been increasingly used in surgeries and other medical procedures, providing more precise and efficient outcomes. Additionally, a wall painting robot has been developed, eliminating the need for manual labor in this tedious task. Moreover, the ABB robot arm has become a popular choice in industrial automation, offering high-speed and accurate movements. Lastly, mining robot solutions have been employed to enhance safety and productivity in mining operations.

Contact Now

Mir Amr Robots Solution:Mir Amr Robots Solution is a cutting-edge technology that specializes in machinery automation and robotics. It offers innovative solutions for various industries, including manufacturing and production. One of its remarkable products is the Lesta Painting Robot, which revolutionizes the painting process in industrial settings.The Lesta Painting Robot is designed with advanced features that enhance efficiency and precision. It uses state-of-the-art technology to automate the painting process, eliminating the need for manual labor.

Contact Now

Robots Used In Transportation:Robots Used In Transportation, Robotics In Warehouse Material Handling, Robotic Parts Suppliers, and Painting Robot For Sale are significant developments in the field of automation. Robots used in transportation offer increased efficiency, safety, and cost-saving benefits. They can work without rest, minimizing human error and optimizing logistics. Robotics in warehouse material handling bring enhanced productivity and accuracy, streamlining operations and reducing labor costs.

Contact Now

Service Robot Industry:The service robot industry has witnessed significant growth in recent years. With advancements in robotics technology, robots are now being used in various sectors, including shipbuilding and construction. In shipbuilding, robots are employed to perform tasks such as welding, painting, and cleaning, improving efficiency and reducing human error. Similarly, in the construction industry, robots are used for tasks like bricklaying and concrete pouring, enhancing productivity and safety.

Contact Now

Process Automation Robotics:Technological advancements in palletizing robots, energy robotics, painting robots, automatic label spot welding robots, labeling robots, and Industry Robots have brought about significant improvements in process automation robotics. Advancements in palletizing robots have greatly improved the speed and accuracy of assembly lines, resulting in faster production output. Meanwhile, advancements in energy robotics have helped minimize risks, reduce labor costs and increase accuracy in the renewable energy sector.

Contact Now

Robots Technology In Steel Industry:Robots Technology in the Steel Industry has witnessed significant advancements in recent years. The introduction of new robots technology has greatly increased efficiency and productivity in this sector. The advantages of robotics technology cannot be overstated.With the implementation of robots technology, steel manufacturers have experienced a remarkable improvement in their operational efficiency. These robots can perform repetitive tasks with precision and speed, resulting in increased output.

Contact Now

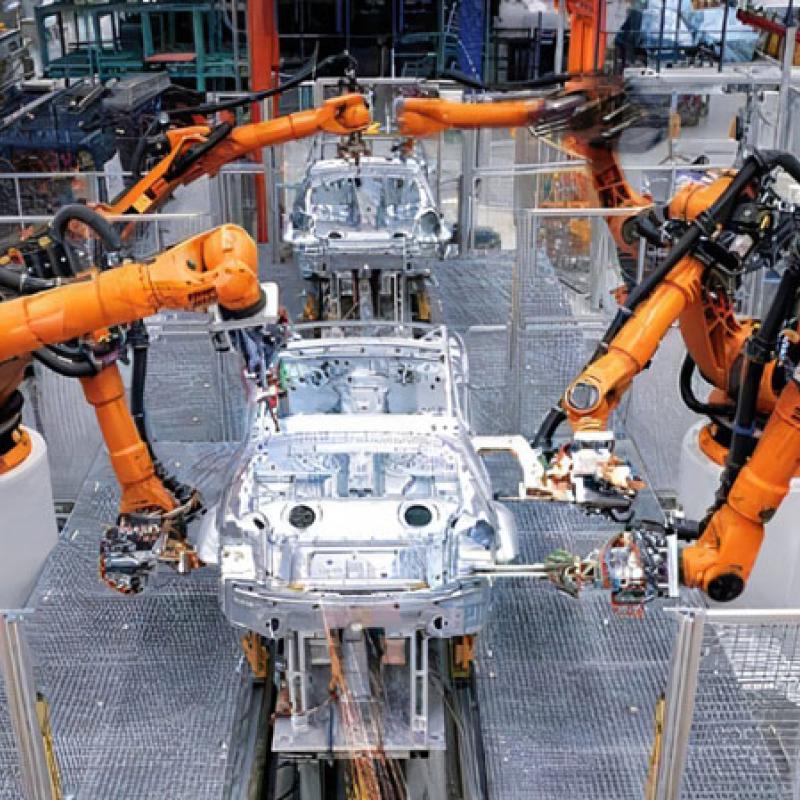

Robotic Arm In Automotive Industry Solution:The automotive industry has witnessed significant advancements with the integration of robotic arms. Robotic arms have become an integral part of car factories, shaping the future of the industry. These powerful machines are utilized in various stages of production, from assembly to painting, ensuring precision and efficiency. In China, the use of robots in car factories has revolutionized the car manufacturing process.

Contact Now

Companies That Use Robots In Manufacturing:Companies that use robots in manufacturing, such as ATI Robotics Solutions and Advanced Robotics Technology, are at the forefront of technological advancements in the industry. These companies understand the benefits of integrating robot arms into their production processes. Robot arms, like those provided by ATI Robotics Solutions, offer precision, speed, and efficiency, leading to increased productivity and reduced costs Advanced.

Contact Now

Robots In Steel Industry:Robots have revolutionized the steel industry with the introduction of advanced technologies. The Gantry Automation System allows for efficient material handling and streamlines the production process. Robotic Arms using Arduino provide precise control and accuracy in performing complex tasks. Moreover, Personal Service Robots assist in various roles, such as maintenance and inspection, ensuring safety and efficiency. With these advancements, the steel industry has experienced improved productivity, enhanced safety, and superior product quality.

Contact Now

Carbon Block Distributed Task Allocation Robots:Carbon Block Distributed Task Allocation Robots are state-of-the-art robots that can efficiently allocate tasks among themselves, resulting in increased productivity. Among the many types of robots available, a Wall Painting Robot is especially useful for painting large areas quickly and accurately. Automated Robotic Machinery, on the other hand, is essential for mass production and can significantly cut down on labor costs.

Contact Now

Manufacturing Robots Solution:Manufacturing Robots Solution, including the Painting Robot Solution, Energy Robotics Solution, and Cylindrical Robot Solution, offers numerous advantages for various industries. These solutions automate repetitive tasks increasing productivity while reducing human error. The Painting Robot Solution ensures consistent and high-quality paint application. The Energy Robotics Solution optimizes energy consumption by employing robots in energy-intensive processes.

Contact Now

Industrial Robots By Country:Industrial Robots By Country, such as the Autonomous Wall Painting Robot, High Precision Robotic Arm, and Hydraulic Robot Arm Industrial, offer significant advantages in various industries. These robots greatly enhance productivity and efficiency in manufacturing processes by performing tasks with precision and accuracy. The Autonomous Wall Painting Robot can swiftly and flawlessly paint large surfaces, saving time and ensuring consistent quality.

Contact Now

Wiautomation AuWiautomation AU, coupled with the impact of robotics in aerospace engineering, offers significant advantages. Wiautomation AU provides a wide range of automation solutions, including robotics, to cater to the specific requirements of the aerospace industry. The Kuka Kr 360, available through Wiautomation AU, offers high precision and versatility, making it suitable for complex aerospace applications. Additionally, the use of painting robots in industries, facilitated by Wiautomation AU, enhances efficiency and quality in the painting process.

Contact Now

Fast Food RobotsFast Food Robots, Ifr Robotics Solution, Robot Industri Solution, and New Robotics Technology 2022 are all innovative advancements in the field of robotics. These technologies are revolutionizing various industries by automating tasks and increasing efficiency.Fast Food Robots are being used in the food industry to streamline the process of preparing and serving meals. These robots can efficiently handle tasks such as taking orders, cooking, and even delivering food to customers' tables.

Contact Now

Need Of Robots In Industries:Robots have become an indispensable component in various industries today. The need for robots in industries arises from their ability to perform tasks efficiently, accurately, and tirelessly. They contribute to increased productivity, reduced labor costs, and improved product quality.Understanding the fundamentals of robot technology is essential for its successful implementation. It involves knowledge of programming, sensors, actuators, and control systems.

Contact Now

Robot In Automotive Industry Solution:Robots play a crucial role in the automotive industry. Their use in car manufacturing offers several advantages. Robots provide precision and accuracy, ensuring high-quality vehicles. They are efficient and can work at a faster pace than humans, increasing productivity. They excel at repetitive tasks and can work consistently without fatigue. Moreover, robots can perform hazardous jobs, enhancing worker safety. Some common robot applications in the automotive industry include welding, painting, and assembly. However, there are also some disadvantages.

Contact Now

Robots Used In FactoriesRobots are widely used in factories for manufacturing automation. Kuka HQ is a renowned company specializing in robotics and manufacturing automation. One of their notable creations is the substation inspection robot. This robot is designed to inspect substations, ensuring their proper functioning and safety. With the advancement of robotics technology, factories are becoming more efficient and safer.

Contact Now

Robots In Food Production:The Japanese robotics industry has always been at the forefront of technological innovation, and one area where they have excelled is in food production. With the introduction of robots in food production, companies have been able to streamline their processes and improve efficiency. One such example is the low-cost industrial robot, Kuka Kr 270. This robot has revolutionized the industry with its advanced features and affordable price point. Its precision and versatility have made it a popular choice for many food production companies.

Contact Now

Robot Technology In Hospitality Industry:Robot Technology in the Hospitality Industry has revolutionized the way tasks are performed. One example of this is the Durr Painting Robot, which is used in hotels to efficiently paint rooms and hallways. This robotic system not only speeds up the process but also ensures a high level of accuracy and consistency in the finished product.Another significant advancement in the industry is the use of articulated industrial robots. These robots can perform a range of tasks such as cleaning, room service, and even concierge services.

Contact Now

Demolition Robots In Construction:Demolition Robots in Construction, as highlighted in the "IFR World Robotics 2022" report, have revolutionized the industry. With advanced features and technology, robots like the ROS Motoman and Kuka KR 3 R540 offer cutting-edge solutions. These robots are specifically designed for demolition tasks, allowing for precise and controlled dismantling of structures. Equipped with powerful tools, they ensure safe and efficient operations, reducing human risks and increasing productivity.

Contact Now