Six Axis Articulated Robot:Robots have played a significant role in revolutionizing the manufacturing industry. One type of robot that has gained popularity is the Six Axis Articulated Robot. This versatile robot is equipped with six axes of movement, providing it with a wide range of motion and dexterity. It can perform complex tasks with precision and accuracy, making it ideal for various applications in the manufacturing process.Another type of robot commonly used in automated manufacturing is the Automated Manufacturing Robot.

Contact Now

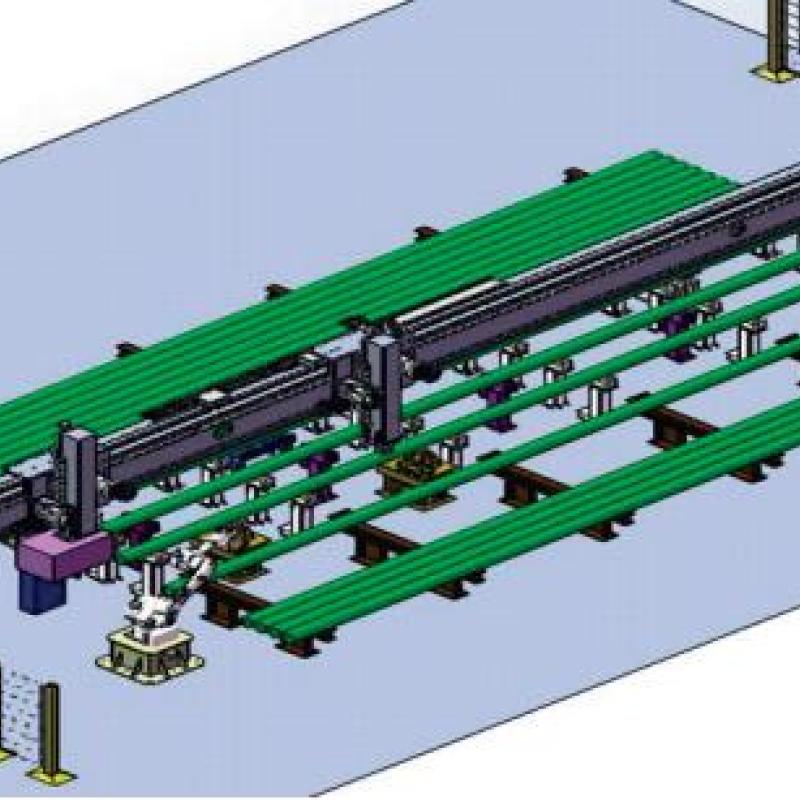

The system realizes automatic assembly of parts, automatic spot welding, automatic full welding, and other actions by integrating a six-axis handling robot, six-axis welding robot, 3D camera, 2D camera, and displacement machine to achieve fully automatic assembly and welding of parts.DSHJ-10RSWeldable materials: carbon steel, alloy steel, stainless steel, aluminum, copper, titanium and their alloysThe system realizes automatic assembly of parts, automatic spot welding, automatic full welding, and other actions by integrating a six-axis handling robot, six-axis welding robot, 3D camera, 2D came

Contact Now

The equipment can realize automatic salvage of scum in galvanized zinc pool of steel plate. The scum in the zinc pool is concentrated to the designated area by manual slag removal, and the six-axis robot automatically salvages the scum in the area. The equipment is equipped with a liquid level measuring device, which can automatically adjust the slag fishing trajectory according to the change of the zinc liquid level.

Contact Now

Cartesian Robot System Solution:The Cartesian Robot System Solution is an efficient and reliable automation solution used in industrial robotics. It offers precise and accurate movements, making it ideal for various applications. One popular choice is the ABB Six Axis Robot, specifically the ABB IRB 460. This robot is known for its versatility and high performance. However, the price of the ABB IRB 460 may vary depending on the configuration and additional features required.

Contact Now

Automatic Unbundling RobotDevice Description/Instruction:The device automatically removes the strapping on the steel coil using a six-axis robot and a special stripping mechanism. It can significantlyimprove the efficiency of on-site tape removal, reduce labor, and avoid potential safety hazards.

Contact Now

The production line is a flexible automatic production line. By using 2D vision to identify the type of workpiece, six-axis robot to automatically grasp the loading, 3D vision to detect dimensional errors, and six-axis robot palletizing, the overall automation of automatic processing, automatic inspection, and automatic palletizing of automotive parts such as axle housings are realized. It is compatible with a variety of bridge shell products.

Contact Now

In the process of coil circulation, labels need to be pasted on the surface for identification. Through the connection between the six-axis robot system and the on-site MES system, it can automatically print labels, paste labels, and check label information. The system has the ability to identify the inner and outer diameter of the steel coil, identify the width of the steel coil, and check the weight information.DSTB-NW23Coil diameter: φ800 ~ φ2100mm;Steel coil width: 800 ~ 1650mm;Labeling position: inner ring and outer ring;Label size: 100mm × 200mm.

Contact Now

The device automatically removes the strapping on the steel coil using a six-axis robot and a special stripping mechanism. Automatic Unbundling Robot Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.It can significantly improve the efficiency of on-site tape removal, reduce labor, and avoid potential safety hazards.

Contact Now

The billet welding label robot is widely used in the billet continuous casting production line to realize the tracking of billets one by one, replacing labor, improving work efficiency, and improving the working environment of front-line workers.The system consists of a six-axis robot, a vision system, an automatic welding gun, a label printer, and an automatic feeding device for welding studs. The label printer can print the required information on the label according to the information sent by the MES system.

Contact Now

6 Axis Articulated Robot:The industrial robotics landscape is evolving rapidly with technologies like the 6 Axis Articulated Robot, Mir Mobile Industrial Robots, Ur20 Universal Robots, and Robotics as a Service companies.The 6 Axis Articulated Robot offers exceptional flexibility and agility in its movements, making it suitable for a wide range of applications.

Contact Now

This assembly line is a versatile automated manufacturing line, which realizes the automated meeting of steerage knuckle meeting for heavy vehicles via way of means of the usage of a six-axis robot, 2D imaginative and prescient system, 3-D imaginative and prescient system, and servo press. It is well suited with the automated manufacturing of greater than twenty varieties of guidance knuckle products. There isn't anyt any guide operation role withinside the line, that could meet the manufacturing of the unique shape guidance knuckle and different vehiclemobile parts.

Contact Now

Automatic labeling robot In the process of coil circulation, labels need to be pasted on the surface for identification. Through the cennection between the six-axis robot system and the on-site MES system, it can automatically print labels, paste labels, and check label information. The system has the ability to identify the inner and outer diameter of the steel coil, identify the width of the steel coil, and check the weight information.Please contact us for more details.

Contact Now

Automatic Zinc Slag Salvaging RobotDevice Description/ Instruction: The equipment can realize automatic salvage of scum in galvanized zinc pool of steel plate. The scum in the zinc pool is concentrated to the designated area by manual slag removal, and the six-axis robot automatically salvages the scum in the area. The equipment is equipped with a liquid level measuring device, which can automatically adjust the slag fishing trajectory according to the change of the zinc liquid level.

Contact Now

Multi-Axis Linkage Welding Robot:The use of Multi-Axis Linkage Welding Robots, such as the Advanced Robotic Construction system, is revolutionizing the manufacturing industry. These robots offer high precision, flexibility, and efficiency in welding operations, resulting in improved weld quality and reduced production time. Additionally, they enhance worker safety by minimizing human involvement in hazardous tasks.While the initial cost of manufacturing robots can be high, they prove to be a worthwhile investment in the long run.

Contact Now

Four Axis Scara Robot:The Four Axis Scara Robot is an innovative automation solution that offers high-speed and accurate performance, making it an ideal choice for various industries. In the food service sector, there are several companies that have leveraged robotics to improve efficiency and customer experience. These food service robotics companies integrate cutting-edge technology to automate tasks such as food preparation and delivery.Another technological advancement worth mentioning is robotic solar cleaning technology.

Contact Now

Scara Robot z Axis:Scara Robot z Axis, along with the utilization of robots in logistics, the mining industry, and the IT industry, has significantly transformed the landscape of industrial automation.The Scara Robot's z-axis functionality plays a crucial role in streamlining logistics operations. By incorporating vertical motion, the robot can efficiently stack and arrange items in a warehouse or distribution center, optimizing storage space and increasing inventory throughput.

Contact Now

In the actual application case through the 9-axis linkage can achieve different lengths and different directions of welding needs, to achieve the requirements of fast and uninterrupted welding, improve welding quality and save welding time.Multi-axis Linkage Welding Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters. The automatic position finding system can be installed to achieve automatic positioning correction of the weld seam within the range allowed by the system to ensure the welding quality.

Contact Now

Kuka 7 Axis Robot Price:The Kuka 7 Axis Robot offers a range of benefits for industrial automation applications. With its versatility, it can handle complex tasks with precision and efficiency. The robot's significant payload capacity allows it to handle heavy objects, improving productivity in industries like automotive manufacturing. Additionally, the seven-axis design provides enhanced reach and range, allowing the robot to access confined spaces and work on larger workpieces.

Contact Now

Automatic Zinc Slag Salvaging Robot System The robot system for the automatic collection of zinc slag enables the automated retrieval of impurities from the galvanized steel plate's zinc pool. Manual slagging concentrates the impurities in a designated area, which are then picked up by the six-axis robot system.The system is equipped with a liquid level height measuring device that automatically adjusts the dredge track basedon changes in the zinc liquid's level. Additionally, it features automatic weighing and statistical functions to facilitateunmanned operations.

Contact Now

Automatic Labeling RobotDevice Description/Instruction: In the process of coil circulation, labels need to be pasted on the surface for identification. Through the connection between the six-axis robotsystem and the on-site MES system, it can automatically print labels,paste labels, and check label information. The system has the ability to identify the inner and outer diameter of the steel coil, identify the width of the steel coil, and check the weight information.

Contact Now

Abb Robot Driver Series:The ABB Robot Driver Series is a reliable choice for soldering and welding applications. Whether using a MIG stick welder or TIG welding wire, these drivers ensure precision and efficiency. With high-precision control algorithms, they enable accurate positioning and seamless coordination between robots and welding equipment. The flexibility of the ABB Robot Driver Series allows for easy integration with various ABB robot models, catering to different soldering and welding requirements.

Contact Now

Automatic Steel Coil Labeling Robot SystemThe automatic steel coil labeling robot system is designed to apply labels on the surface of steel coils for identificationpurposes during the circulation process.Integrating a six-axis robot system with an on-site MES system enables automated label printing, application, and information verification.This efficient system accurately determines the inner and outer diameter of the steel coil, identifies its width, and verifies weight information.

Contact Now