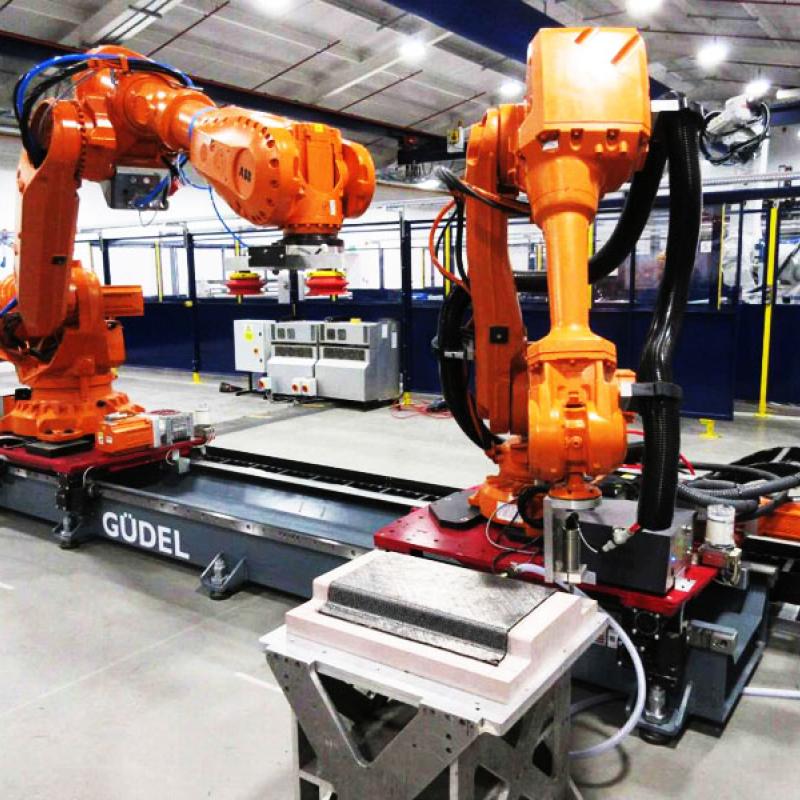

Abb Foundry Robots Solution:ABB Foundry Robots are revolutionizing the manufacturing industry with their advanced technology and high precision. These robots are specifically designed for harsh environments, making them perfect for tasks such as casting. The introduction of Casting Soft Robot, a more flexible and adaptable version, has further enhanced the efficiency and safety of the process. Foundry Plus Robot, another variant, offers additional features and benefits, tailored to meet the specific needs of a foundry.

Contact Now

Abb Foundry Robot Solution:ABB Foundry Robots are primarily used in industries for tasks such as material handling, machine tending, casting, die casting, and spot welding. They are designed to withstand harsh and high-temperature environments. These robots increase productivity, improve quality, and enhance safety in the workplace. They are also used in the automotive industry for tasks such as assembly, painting, and welding. ABB Foundry Robots are also capable of performing more complex tasks, such as 3D printing, with precision and accuracy.

Contact Now

Robots For Foundry Solution:Robots for Foundry are revolutionizing the industry, making processes more efficient and safer. One company leading this change is DeSheng Robot Foundry. Their advanced robotic systems are designed to handle a variety of tasks, from molding and casting to finishing and inspection, reducing human error and increasing productivity. DeSheng Robot Foundry reviews from customers highlight the company's commitment to quality and innovation. Users praise the robots for their precision, reliability, and ease of use.

Contact Now

Robot In Foundry Solution:Robot Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.Robots in a foundry are used to automate tasks such as pouring, casting, and finishing. To use them, first, program the robot with the specific task it needs to perform. This could be done using a software interface provided by the robot manufacturer. Then, position the robot in the correct place in the production line. Ensure safety measures are in place to protect human workers.

Contact Now

Robotics In Foundry Solution:Robotics in foundry is characterized by automation, precision, and efficiency. Robotics In Foundry Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters. These robots are designed to handle high-temperature, high-risk tasks such as pouring molten metal, removing castings, and finishing operations. They are programmed to perform repetitive tasks with high accuracy, reducing human error and increasing productivity.

Contact Now

Foundry Robotic Automation Solution:In the realm of industrial automation, Foundry Robotic Automation has revolutionized the casting process. These robots, such as the Tale Foundry Robot and the Kuka Foundry Robot, are designed to handle high temperatures and harsh environments, providing a safer and more efficient alternative to manual labor. They are capable of performing precise, repetitive tasks, such as pouring molten metal into molds, with consistent accuracy.

Contact Now

Robotics In Foundry Solution:Robotics in foundry applications has revolutionized the manufacturing industry. Robotics In Foundry Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.Robots are used for tasks such as casting, molding, and finishing, reducing human involvement and increasing efficiency and precision. They can withstand harsh conditions, including high temperatures and dust, ensuring consistent production quality.

Contact Now

Robotics For Foundry Solution:The future of robotics in the foundry industry looks promising. With advancements in technology, robots can perform tasks with higher precision and speed, increasing productivity and reducing errors. They can also work in hazardous environments, improving safety standards. The integration of AI and machine learning can further enhance their capabilities, enabling predictive maintenance and real-time decision making. Furthermore, the adoption of robotics can lead to significant cost savings in the long run.

Contact Now

Kuka Foundry RobotKuka Foundry Robot, Kuka Linear Robot, and Tx Scara Robot are three advanced robotic systems developed by The High Tech Robotic Systemz Ltd. These robots are equipped with cutting-edge technology and are designed to perform complex tasks with precision and efficiency. With their advanced features and capabilities, these robots are revolutionizing the manufacturing industry and enhancing productivity. The High Tech Robotic Systemz Ltd continues to innovate and develop state-of-the-art robotic solutions to meet the ever-evolving needs of industries worldwide.

Contact Now

Mecademic 500Mecademic 500, ABB Foundry Robot, Cleaning Robot Technology, and Pick and Place Automation Equipment are innovative technologies that have revolutionized various industries. These advanced machines have enhanced productivity, efficiency, and accuracy in tasks such as assembly, cleaning, and material handling. With their precise movements and intelligent programming, they have become indispensable tools for businesses worldwide.

Contact Now

Abb Robot Driver Series:The ABB Robot Driver Series is a reliable choice for soldering and welding applications. Whether using a MIG stick welder or TIG welding wire, these drivers ensure precision and efficiency. With high-precision control algorithms, they enable accurate positioning and seamless coordination between robots and welding equipment. The flexibility of the ABB Robot Driver Series allows for easy integration with various ABB robot models, catering to different soldering and welding requirements.

Contact Now

Abb Irb 1300 SolutionThe ABB IRB 1300 solution, known for its exceptional performance, is a popular choice in the industrial automation sector. Despite its advantages, many businesses may be concerned about the ABB robot price. However, it's important to consider the long-term benefits and return on investment provided by this articulated robot arm. With its advanced features and compliance with safety standards such as ANSI RIA R15.06, the ABB IRB 1300 solution offers unparalleled precision, versatility, and efficiency.

Contact Now

Abb Robot With Arc Welding:Industrial automation has revolutionized various industries, and three key components of this progress are the ABB Robot with Arc Welding, KUKA Food Robot, and the designing of a robotic arm. The ABB Robot with Arc Welding is a cutting-edge technology that enhances efficiency and precision in welding processes. It ensures consistent weld quality, reduces errors, and enhances overall productivity. The KUKA Food Robot, on the other hand, is specifically designed for the food industry. It ensures food safety and hygiene while increasing production speed and accuracy.

Contact Now

Abb 3d PrintingABB 3D Printing, Offshore Robotics, Excellence Automation And Robotics, and Neya Robotics are leaders in the field of robotics and automation. ABB's advanced 3D printing technology enables faster production, cost savings, and design flexibility. Offshore Robotics specializes in autonomous systems for offshore operations, enhancing safety and efficiency. Excellence Automation And Robotics offers cutting-edge solutions for industrial automation, improving productivity and accuracy.

Contact Now

Abb Collaborative RobotABB Collaborative Robot, Process Automation Robotics, KUKA KR 16, and KUKA KR C4 are efficient and advanced solutions in the field of automation.ABB Collaborative Robot offers safe collaboration with human workers, streamlining processes in industries such as manufacturing and logistics.Process Automation Robotics optimizes workflow efficiency by automating repetitive tasks with high precision and reliability, boosting productivity.KUKA KR 16 is a versatile and agile robot, capable of handling various applications in industries like automotive and electronics manufacturi

Contact Now

Abb Robot Welding ProgramThe use of Abb Robot Welding Program and robotic welding machines has revolutionized the welding industry. These machines, manufactured by leading companies, have greatly increased efficiency and productivity in various sectors. One such industry that has greatly benefited from welding robots is the automotive industry. With the ability to perform complex welding tasks with precision and speed, these robots have become an integral part of automobile manufacturing.

Contact Now

Abb Articulated Robot:ABB Articulated Robot is a popular choice in the industrial sector due to its versatility and precision. It is capable of performing complex tasks with ease, making it a valuable asset for many manufacturing companies.When it comes to industrial robot manufacturers, there are several top players in the market. Some of the leading names include ABB, Fanuc, Yaskawa, KUKA, and Universal Robots.

Contact Now

Abb Irb 6400 Price:The Abb Irb 6400 is a high-performance robot arm widely used in the industrial sector. Its precision and efficiency have made it a popular choice for factories. Speaking of factory automation, mobile robot technology has also made significant advancements. These robots are equipped with advanced sensors and navigation systems, enabling them to navigate factory floors and perform various tasks autonomously. Another emerging technology in automation is Robotic Process Automation (RPA).

Contact Now

Abb Robotics Webshop Expansion:The expansion of the Abb Robotics Webshop brings exciting opportunities for customers interested in Kuka Industrial Robots, including the innovative Kuka Servo Bot. With this expansion, customers can now access and explore a wider range of Kuka Industrial Robots products, including the highly sought-after Kuka Servo Bot. Moreover, the Abb Robotics Welding solutions are now also available through the webshop, enabling customers to easily find and purchase the cutting-edge welding technologies they need.

Contact Now

Abb Scara Robot Automation Solution:Abb Scara Robot Automation Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters, Pentagon Assembly Automation, and German Automation Companies are leaders in the field of automation using PLC (Programmable Logic Controller).Abb Scara Robot Automation is known for its precision, efficiency, and flexibility. With high accuracy and continuous operation, it improves product quality and productivity.Pentagon Assembly Automation specializes in robotic assembly systems.

Contact Now

Abb Robotics CompetitorsABB Robotics Competitors are constantly trying to keep up with the industry leader. Staubli Scara Robot is one of the top contenders, known for its high precision and speed. Mobile Robots In Industry are also gaining popularity, offering flexibility and efficiency in various industrial applications. Open Source Industrial Robot Arm is an innovative solution that allows users to customize and modify the arm according to their specific needs.

Contact Now

Abb Discrete Automation Solution:ABB Discrete Automation, as an automation robotics company, is recognized as one of the top robotic automation companies in the industry. Abb Discrete Automation Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.Their expertise in industrial palletizing robots sets them apart. ABB's Discrete Automation solutions provide advanced automation capabilities to various industries.

Contact Now

Robot In Manufaturing Industries Video:In the realm of manufacturing industries, the integration of robotics has revolutionized production processes. Videos highlighting the efficiency and effectiveness of robots in various manufacturing tasks have become popular. The Robot Foundry has emerged as a pioneer in providing advanced robotic solutions for industrial manufacturing. The concept of Robotics In Industry 5.0 focuses on collaborative robots and human-robot interaction, leading to increased flexibility and productivity.

Contact Now