Warehouse Robotics Technology

Warehouse Robotics Technology

The advantages of Warehouse Robotics Technology include increased efficiency and productivity, reduced labor costs, improved accuracy and precision, enhanced safety, and the ability to handle complex tasks. These robots can work 24/7 without fatigue or breaks, leading to faster order fulfillment and reduced lead times. They can also navigate through narrow aisles and handle heavy loads, optimizing space utilization. With advanced sensors and algorithms, they can perform tasks with high accuracy, minimizing errors and reducing product damage. Additionally, these robots can handle hazardous or repetitive tasks, ensuring the safety of human workers.

Warehouse Robotics Technology

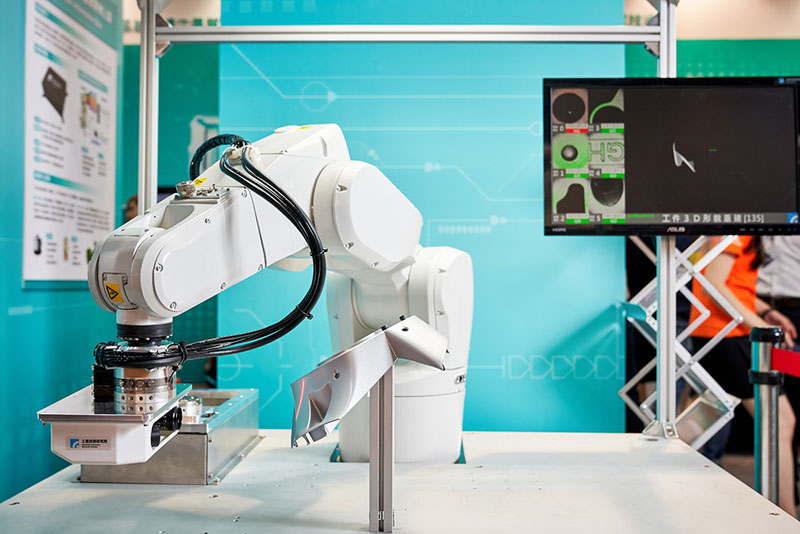

Warehouse Robotics Technology has revolutionized the way goods are stored and moved within warehouses. One such example is the Kuka Kr 60 3, a highly advanced robotic arm that can perform various tasks with precision and efficiency. This technology has significantly increased productivity and reduced human error in warehouse operations.

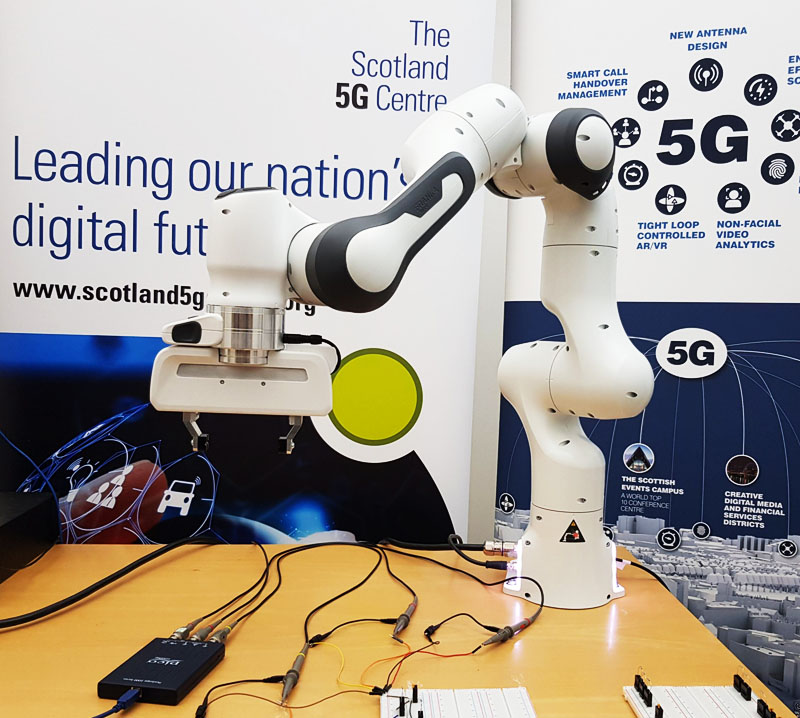

Another innovative technology is Robotic Process Automation as a Service, which automates repetitive tasks and processes. This technology has streamlined operations and improved efficiency by eliminating the need for manual intervention. It has also freed up human resources to focus on more complex and value-added tasks.

Furthermore, the implementation of Ansi Ria 15.06 safety standards ensures the safe and secure operation of warehouse robotics. These standards provide guidelines for the design, installation, and use of robotic systems, ensuring the well-being of workers and preventing accidents.

In conclusion, the integration of Warehouse Robotics Technology, such as the Kuka Kr 60 3, along with Robotic Process Automation as a Service and adherence to Ansi Ria 15.06 safety standards, has transformed warehouse operations. These advancements have not only increased efficiency and productivity but also improved the safety and well-being of workers.