Robotics In Food Industry

Robotics In Food Industry

1,Increased Efficiency: Robotics in the Food Industry automate various tasks, such as packaging, sorting, and processing, leading to improved productivity and reduced labor requirements.

2,Enhanced Food Safety: Robots reduce the risk of contamination by minimizing human contact, ensuring a hygienic and safe food processing environment.

3,Consistent Quality: With precise and standardized movements, robots maintain consistent quality standards in food handling and processing, resulting in reliable product quality.

4,Cost Savings: By automating labor-intensive processes, robotics in the Food Industry reduce labor costs and minimize waste, leading to increased cost-effectiveness.

5,Scalability: Robotics can be easily tailored to meet changing production demands, allowing for scalability and adaptability to varying production volumes.

Robotics In Food Industry

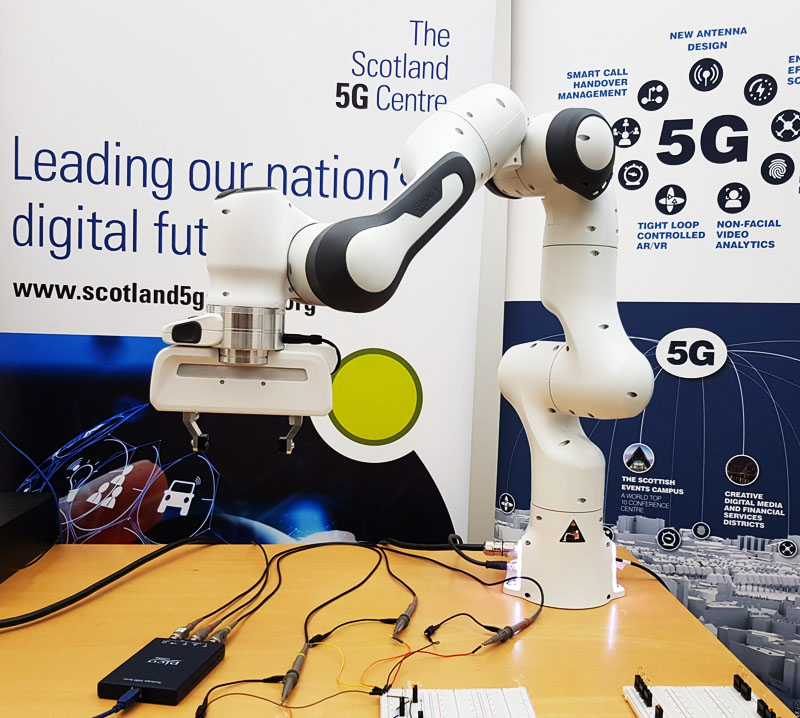

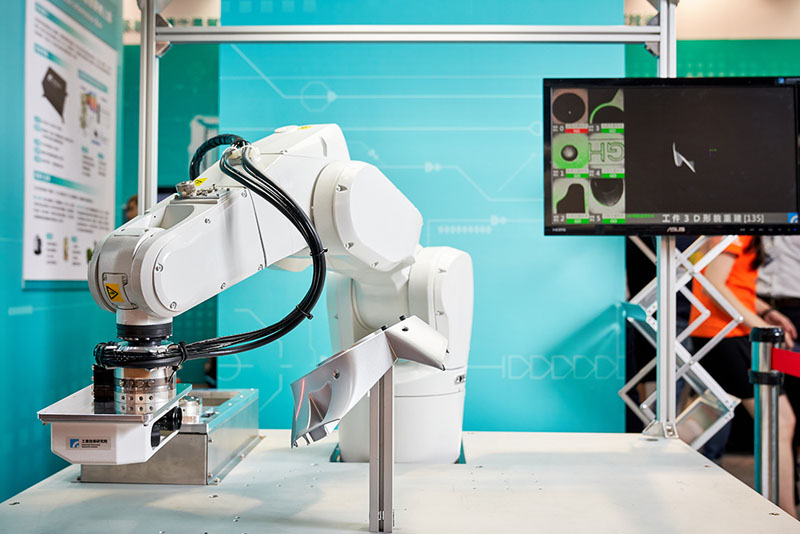

Robotics in the Food Industry, including Universal Robots UR20, ATI Robotics Solution, and ABB Industrial Robots, provide significant benefits to food manufacturing and processing.

Universal Robots UR20 offers flexibility and ease of use for automation in food handling and packaging, increasing efficiency and productivity.

ATI Robotics Solution provides advanced end-of-arm tooling technologies, enabling precise and adaptable gripping, sorting, and processing of food items.

ABB Industrial Robots offer a wide range of robotic solutions tailored to the food industry, streamlining production, ensuring food safety, and improving overall quality.

Through integration and automation, Robotics in the Food Industry optimize processes, enhance food safety, increase productivity, and maintain consistent quality, making them indispensable to the modern food industry.