Mobile Industrial Robotics (MIR)

Advantages of Mobile Industrial Robotics (MIR):

1,Flexibility and Adaptability: Mobile Industrial Robotics (MIR) offers exceptional flexibility and adaptability in various industrial settings. These autonomous robots are designed to navigate and operate in dynamic environments, easily adjusting their routes to avoid obstacles and optimize efficiency. With their ability to handle diverse tasks and adapt to changing workflows, MIR robots provide a versatile and scalable solution for increased productivity.

2,Increased Efficiency and Productivity: MIR robots are known for their ability to streamline material handling and transportation processes, resulting in improved efficiency and productivity. These robots can autonomously transport goods and materials within the facility, eliminating the need for manual transportation tasks. By automating these tasks, MIR robots can complete them faster and with greater accuracy, allowing human workers to focus on more value-added activities.

3,Enhanced Safety and Work Environment: MIR robots prioritize safety in the workplace. Equipped with advanced sensors and intelligent navigation systems, they can detect and avoid collisions with objects or humans in real-time. This ensures a safer working environment, reducing the risk of accidents and injuries. Additionally, by automating physically demanding and repetitive tasks, MIR robots contribute to reducing worker fatigue and improving job satisfaction.

Mobile Industrial Robotics (MIR):

Mobile Industrial Robotics (MIR) has emerged as a game-changer in the automation industry. Industrial automation companies, including CM Industrial Automation, have embraced MIR technology for its numerous benefits. With MIR, material handling and transportation become seamless, optimizing productivity and efficiency. PLC programming for industrial automation ensures precise control and synchronization of MIR robots, allowing smooth coordination within the production process. CM Industrial Automation, equipped with expertise and experience, offers comprehensive solutions in integrating MIR with PLC programming, enabling seamless automation in various industries. Together, MIR and PLC programming are transforming industrial operations, improving productivity, reducing costs, and enhancing overall competitiveness.

PARAMETERS:

SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

Robot arm | Japanese Brand Robot | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand | ||||

Main Performance | Speed Capacity | 8s per cycle | Adjust according to products and arrangement | |

Weight | About 8000kg | |||

Applicable Product | Cartons, cases,bags, | Containers,bottles,cans,buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | SICK | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | Schneider/Siemens | |||

Driving Motor | SEW | |||

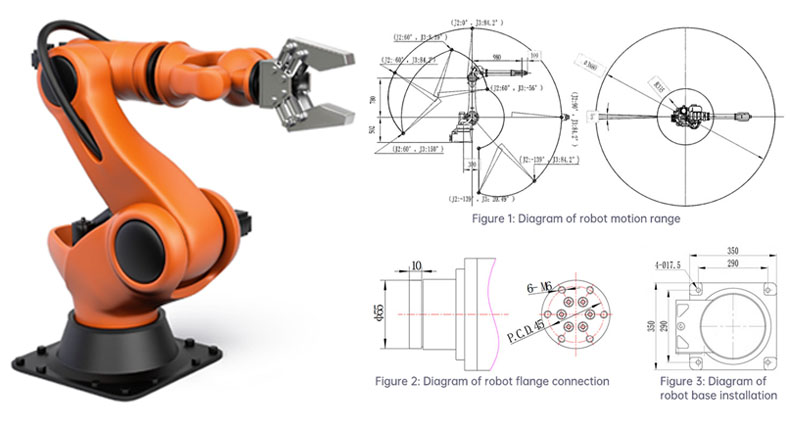

DIMENSIONAL DRAWINGS:

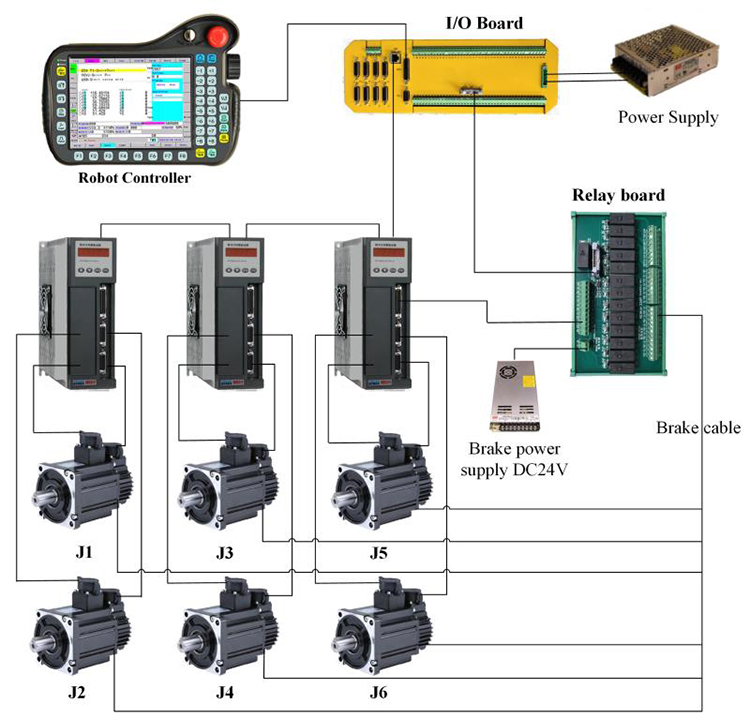

ROBOT CONTROLSYSTEM:

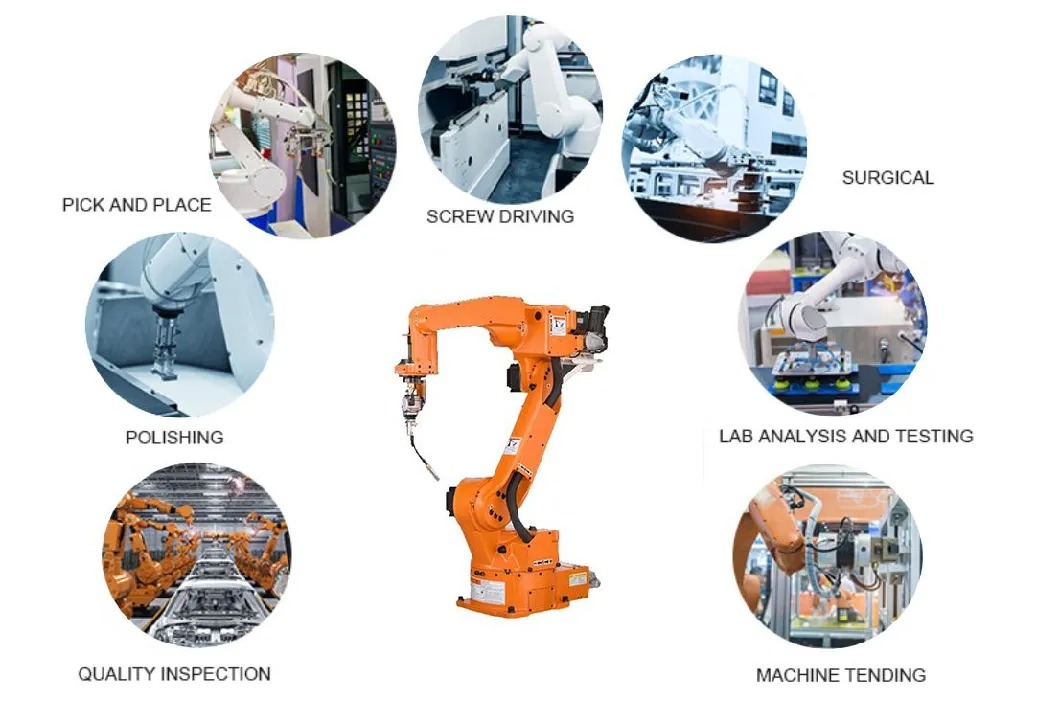

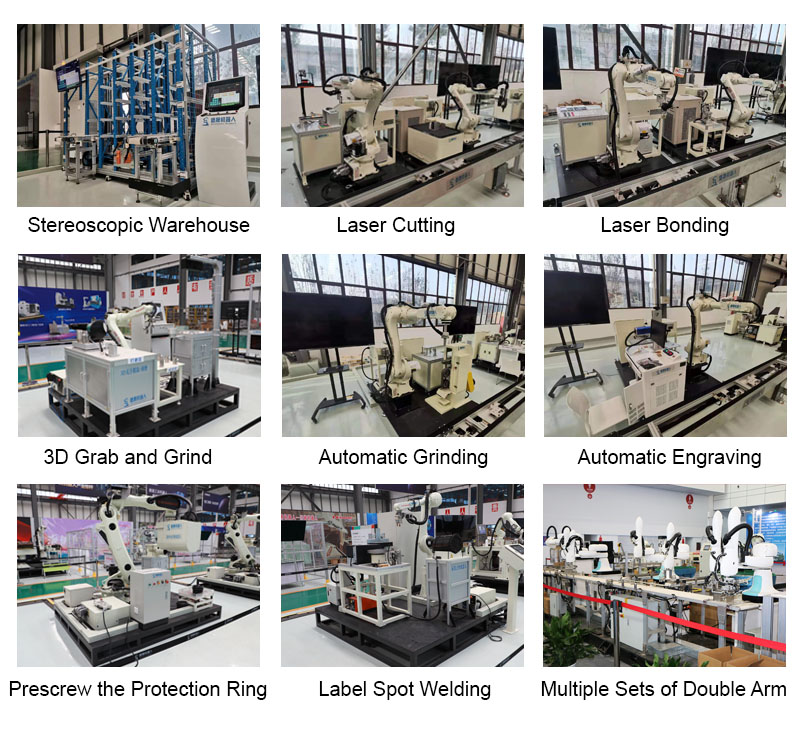

APPLICATIONS:

FEATURES:

1,Autonomous Navigation: Mobile Industrial Robotics (MIR) is equipped with advanced navigation capabilities, allowing them to move autonomously in dynamic environments. These robots navigate using a combination of sensors, cameras, and mapping technology, enabling them to avoid obstacles and adapt to changes in their surroundings. This autonomous navigation feature provides flexibility and agility in various industrial settings.

2,Collaborative Capabilities: MIR robots are designed to work alongside human workers, promoting collaboration and enhancing productivity. These robots can interact safely with humans, detect their presence, and adjust their movements accordingly. Collaborative capabilities enable MIR robots to share workspaces, assist in material handling tasks, and optimize overall efficiency.

3,Customizable Applications: MIR offers customizable applications to cater to specific operational needs. They can be fitted with different equipment and attachments, such as conveyors, lifts, or sensors, to perform various tasks, including material transportation, inventory management, or inspection. The flexibility of MIR allows for easy integration and adaptation to diverse industrial workflows, maximizing their effectiveness in different applications.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: