Advanced Mining Robot Systems

Advantages of Advanced Mining Robot Systems:

1,Increased productivity: Advanced mining robots can operate 24/7 without the need for breaks or rest, leading to significantly increased productivity compared to human workers. They can work in harsh and challenging conditions that may be harmful or inaccessible for humans.

2,Improved safety: With the use of mining robot systems, the risk to human workers is greatly reduced as they can carry out dangerous tasks such as excavation, drilling, and transportation in hazardous environments. This helps minimize accidents and injuries.

3,Precision and accuracy: Mining robots are equipped with advanced sensors and control systems that enable them to operate with high precision and accuracy. They can perform tasks with consistent quality, resulting in improved efficiency and reduced material waste.

Advanced Mining Robot Systems:

Advanced Mining Robot Systems, Equipment Automation Technology, Oil and Gas Automation, and Manufacturing Automation Solutions are all examples of the rapid advancement of automation in various industries. These technologies have revolutionized the way we work by increasing productivity, improving safety, and enhancing accuracy.

Advanced Mining Robot Systems have the potential to increase productivity in the mining industry by operating continuously without breaks. They can work in hazardous conditions, reducing risks to human workers.

Equipment Automation Technology enables machines to operate efficiently and accurately, leading to reduced human error and increased overall productivity. This technology has found applications in various industries such as manufacturing and transportation.

Oil and Gas Automation has optimized the production and extraction processes by automating tasks such as drilling, pumping, and monitoring. This improves efficiency and reduces downtime, ultimately increasing profitability.

Manufacturing Automation Solutions have revolutionized the manufacturing industry by automating assembly lines and reducing the need for manual labor. This not only improves efficiency but also ensures consistent quality in the production process.

In conclusion, these automation technologies have proven to be instrumental in enhancing productivity, safety, and accuracy in various industries. They have changed the way we work and will continue to drive innovation in the future.

PARAMETERS:

SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

Robot arm | Japanese Brand Robot | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand | ||||

Main Performance | Speed Capacity | 8s per cycle | Adjust according to products and arrangement | |

Weight | About 8000kg | |||

Applicable Product | Cartons, cases,bags, | Containers,bottles,cans,buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | SICK | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | Schneider/Siemens | |||

Driving Motor | SEW | |||

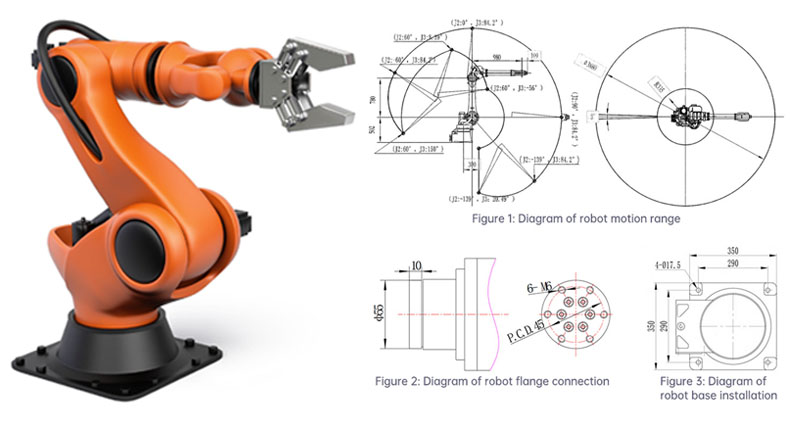

DIMENSIONAL DRAWINGS

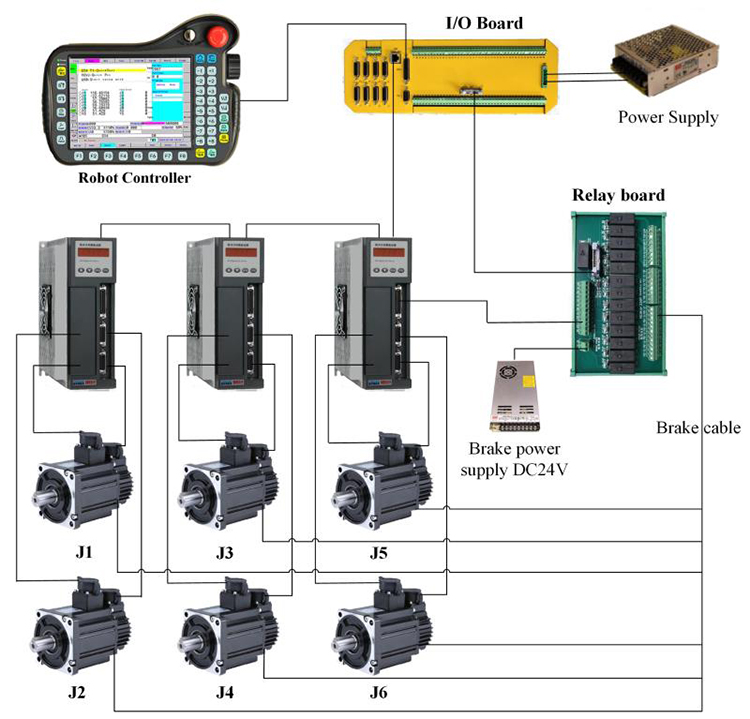

ROBOT CONTROLSYSTEM:

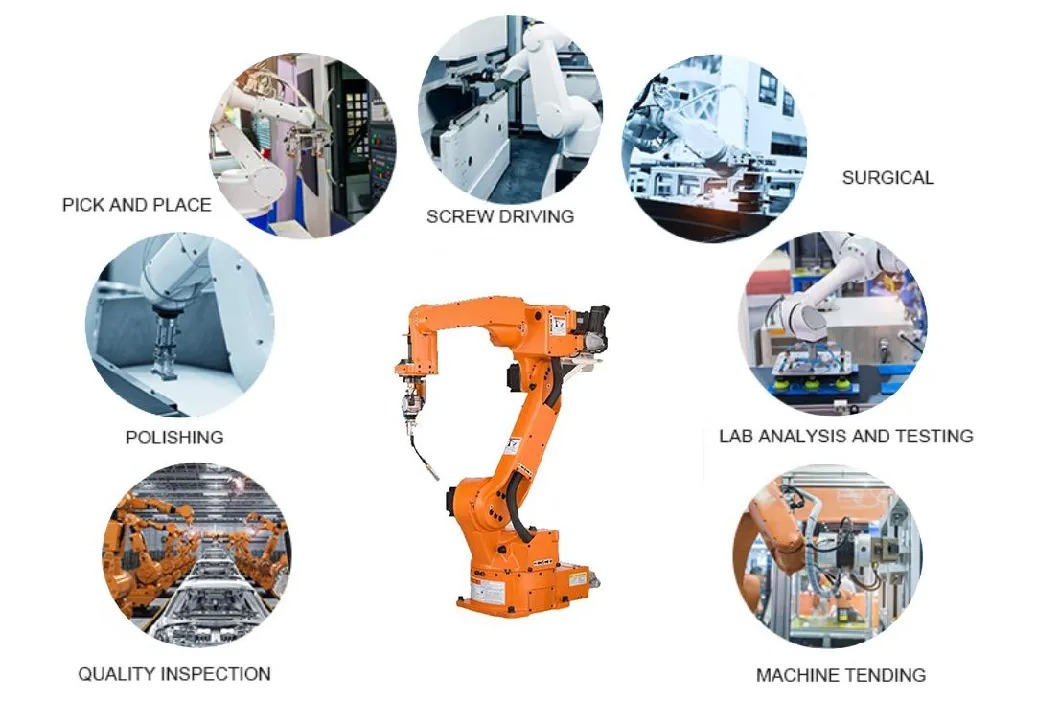

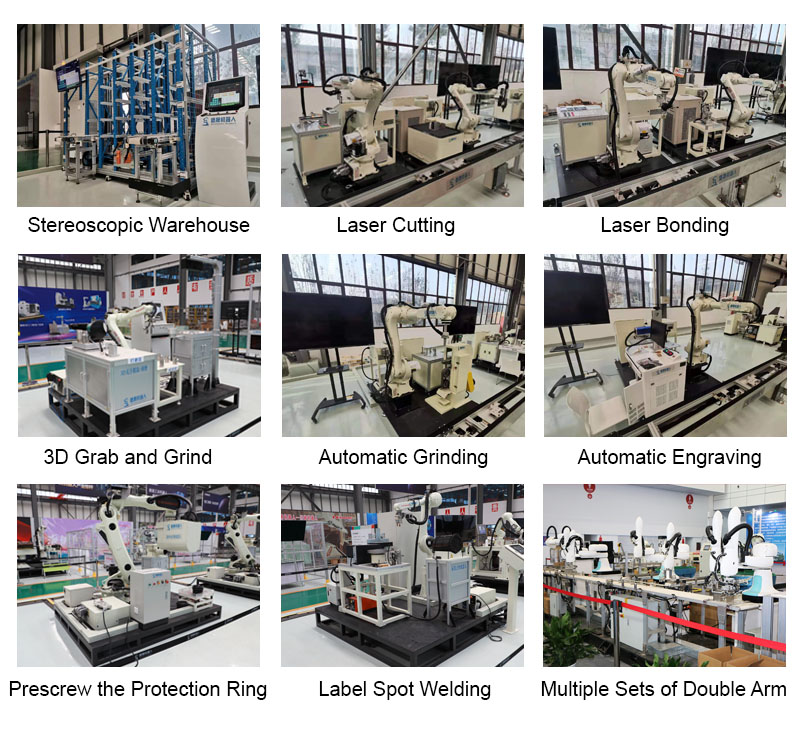

APPLICATIONS:

FEATURES:

1,Versatility: Advanced mining robot systems are designed to adapt to different mining environments and tasks. They can be equipped with various attachments and tools to perform a wide range of functions such as excavation, drilling, and transportation.

2,Autonomy: These robot systems are capable of autonomous operation, meaning they can make decisions and adjust their actions without continuous human intervention. They are equipped with advanced sensors, algorithms, and control systems that enable them to navigate and interact with their surroundings.

3,Safety: Safety is a key characteristic of advanced mining robot systems. They are designed to work in hazardous and challenging mining environments, reducing the risk to human workers. They are equipped with safety features like sensors, emergency stops, and protective barriers to ensure the safety of both the equipment and the operators.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: