5g Robot Framework Solution

5g Robot Framework Solution:

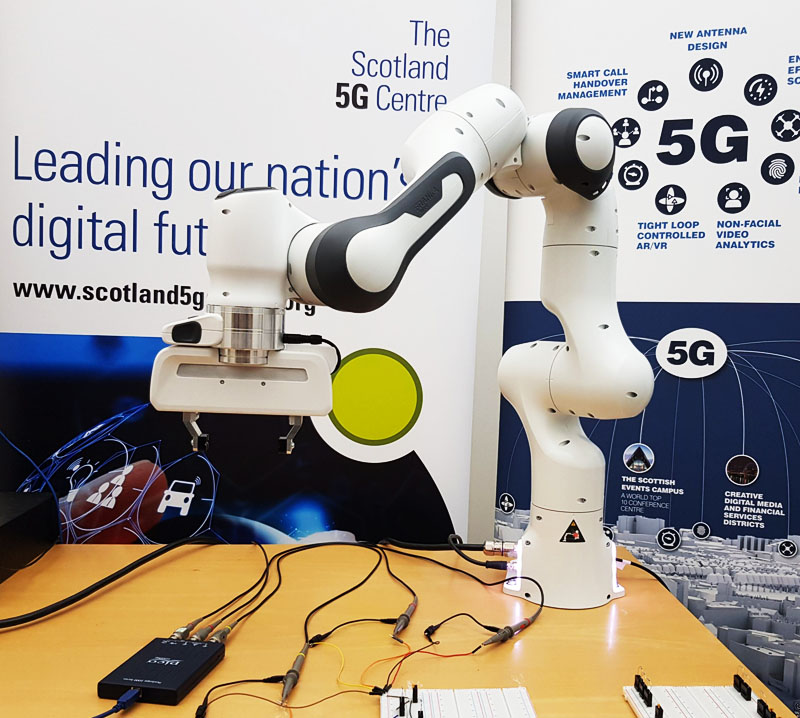

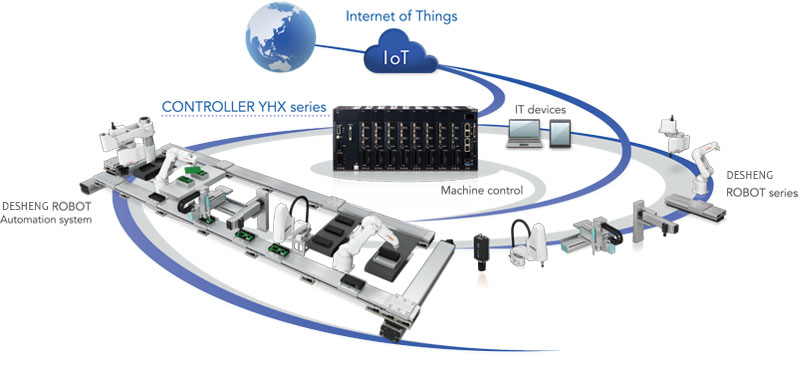

1,Enhanced connectivity: 5G technology provides reliable, high-speed connectivity, enabling seamless communication between robots. This facilitates coordination and collaboration among multiple robots, leading to improved efficiency and productivity.

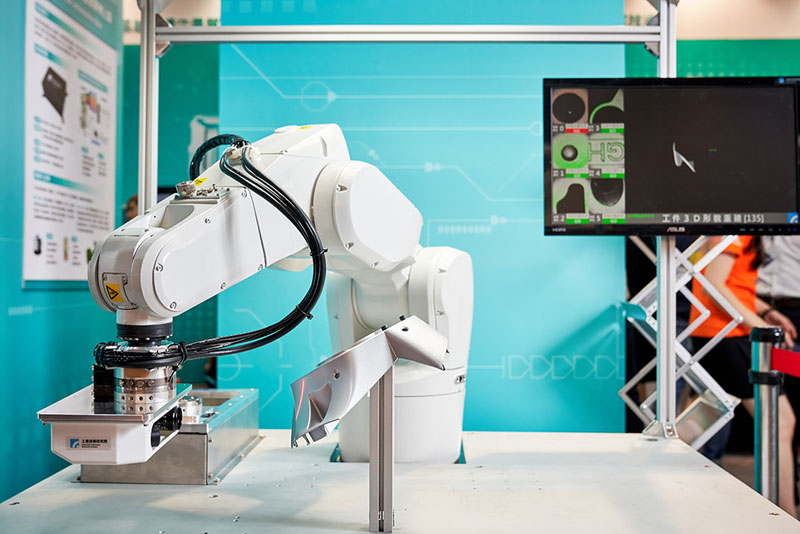

2,Real-time data processing: With 5G, the Robot Framework can handle large amounts of data in real-time. This enables quick decision-making and adaptive behavior in robots, making them more responsive to changing environments and tasks.

3,Versatile applications: The flexible nature of the 5G Robot Framework allows for a wide range of applications across different industries. From manufacturing to healthcare, the framework can adapt and incorporate various robotic systems, enabling intelligent automation and advanced robotics solutions.

Please Contact Us For Detailed Technical Parameters.

5g Robot Framework Solution:

The integration of 5G technology with the Robot Framework has opened up new possibilities in various sectors. For instance, in surgical robotics, 5G technology enables remote robotic surgery, where surgeons can perform procedures from a distant location, leveraging real-time communication and high-speed connectivity. Moreover, the Robot Framework compatible with 5G allows for versatile applications, including advanced automation and intelligent robotics solutions in various industries. Additionally, 5G-compatible robot vacuums offer seamless connectivity and faster data transfer, resulting in efficient cleaning performance and enhanced user experience. The convergence of 5G and the Robot Framework drives innovation and improves the capabilities of robotics in diverse fields.

Specification and model: DSYC-5G01

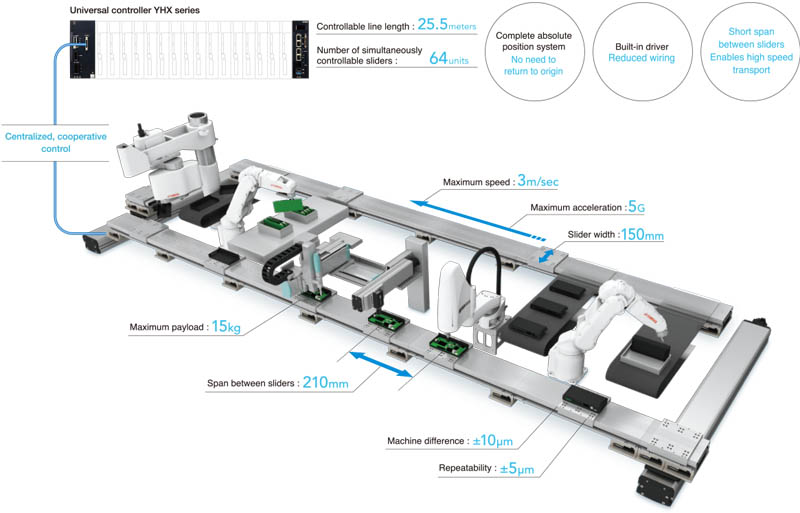

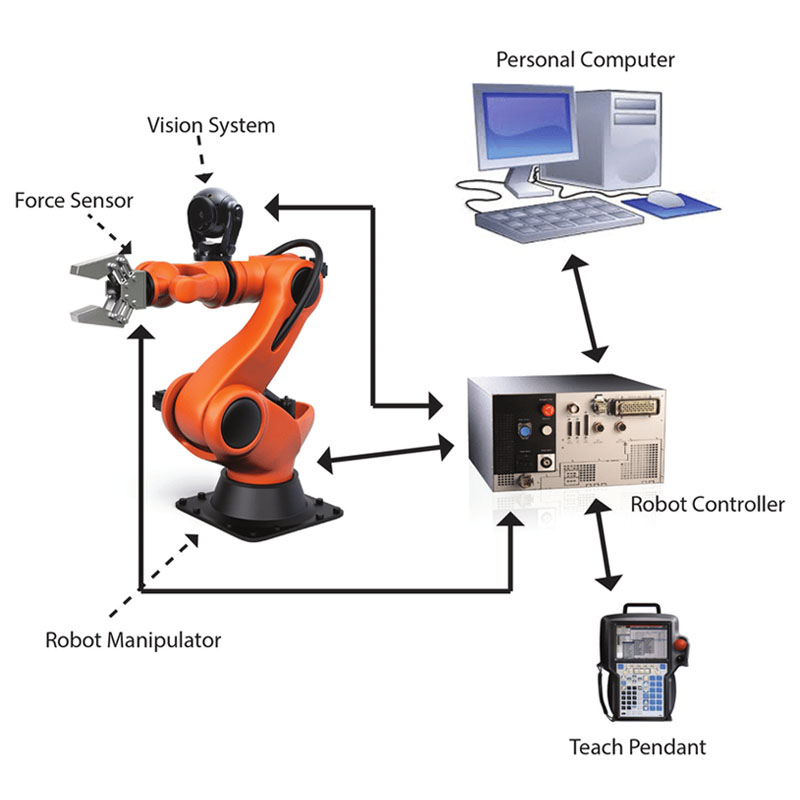

Equipment parameters: 5G+robot remote control, remote diagnosis, remote program modification, cloud deployment data collection.

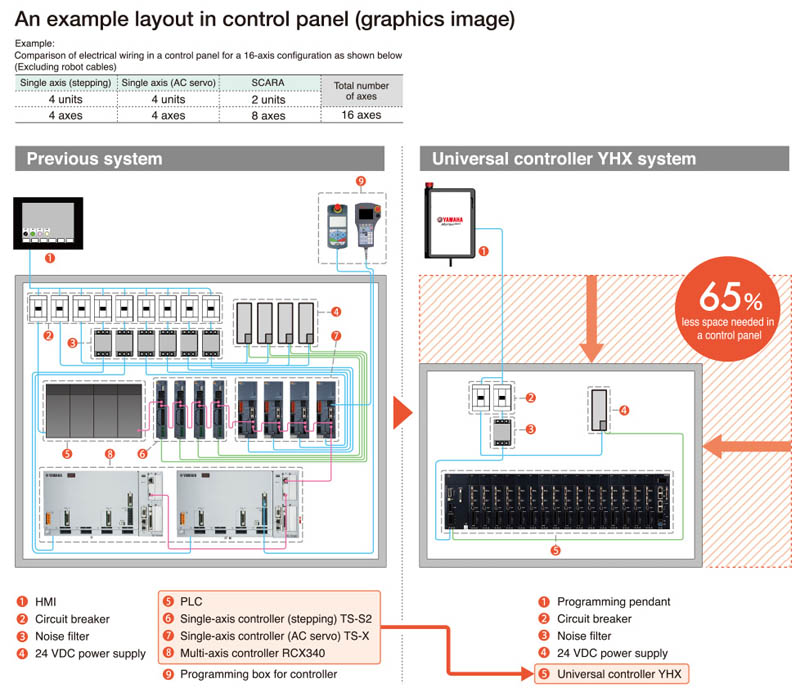

Device Description: The "5G+Robot Operation and Maintenance Shared Platform" utilizes 5G's low latency technology to remotely and real-time view the working status of devices, perform remote control maintenance and data monitoring of robots, quickly locate and solve faults, significantly improve robot work efficiency, and effectively enhance the stability of robots and devices.

The "5G+Robot Operation and Maintenance Shared Platform" achieves real-time visualization of equipment, improves fault resolution speed, can quickly locate and solve faults, reduces fault processing time by 82%, improves one-time fault repair rate by 40%, and saves travel costs by 50%; Reduce non predicted downtime by more than 30%, improve the effective work efficiency of robots, and improve the stability of robots and equipment.

Once an abnormal situation occurs, regulatory personnel can remotely debug the platform based on the displayed data of the cloud platform. Reduced equipment maintenance costs, reduced equipment downtime, improved production efficiency, improved response efficiency of integrators, reduced personnel travel expenses, and reduced company operating costs.

Solved the problems of scarcity of professional technical personnel for industrial robots, lack of a professional talent pool and platform, incomplete personal information collection, reliance on the original manufacturer for maintenance, slow response time, the need to reserve spare parts year-round and occupy a large amount of working capital, and long delivery time.

In 2021, it successfully landed at Baotou Baosteel and was awarded the Shandong Province 5G+Industrial Internet Teacher Training Project and recommended to the Ministry of Industry and Information Technology of the People's Republic of China.