5g Industrial Robots Solution

5g Industrial Robots Solution:

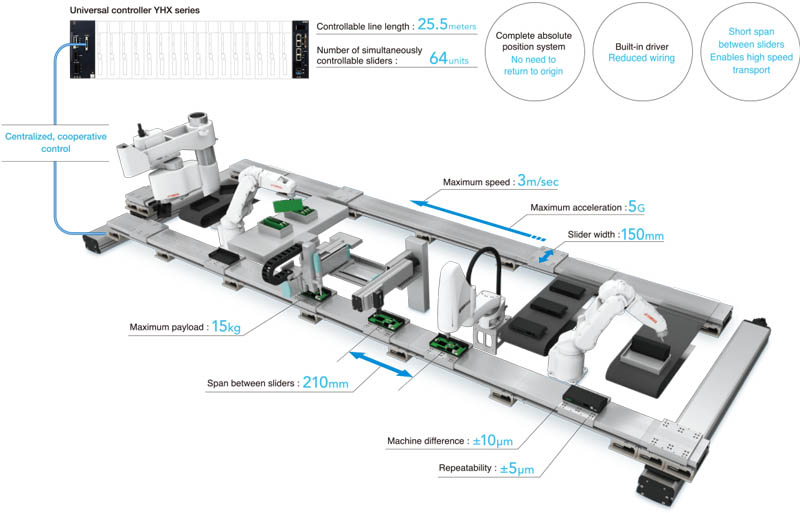

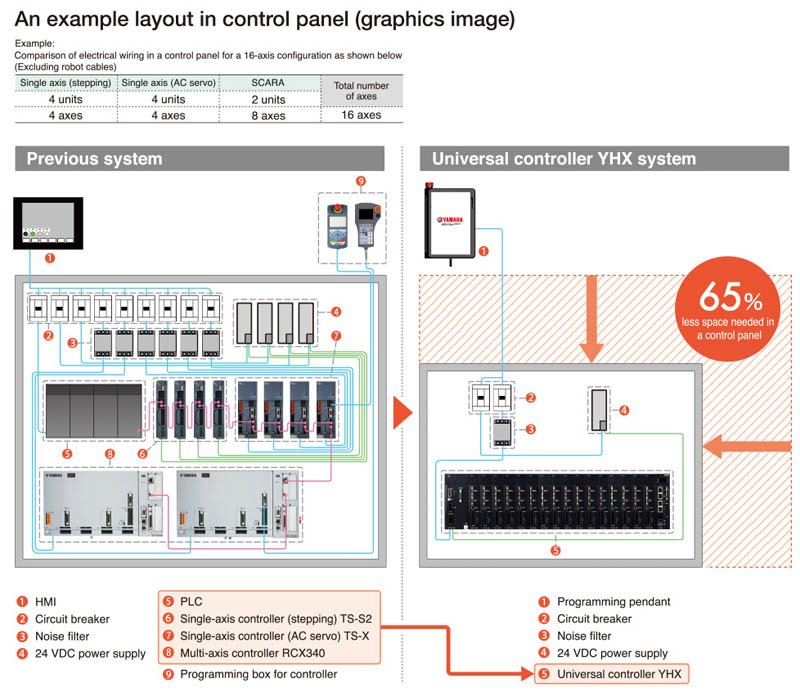

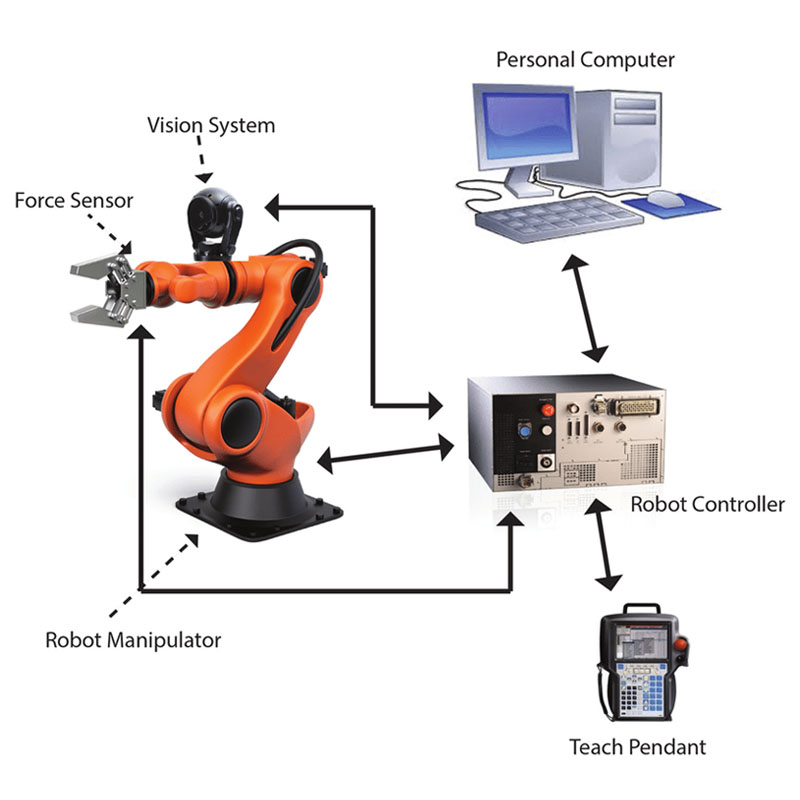

1,Enhanced productivity: 5G enables high-speed data transfer and low latency communication, allowing industrial robots to retrieve and process information quickly. This significantly increases their operational efficiency and productivity.

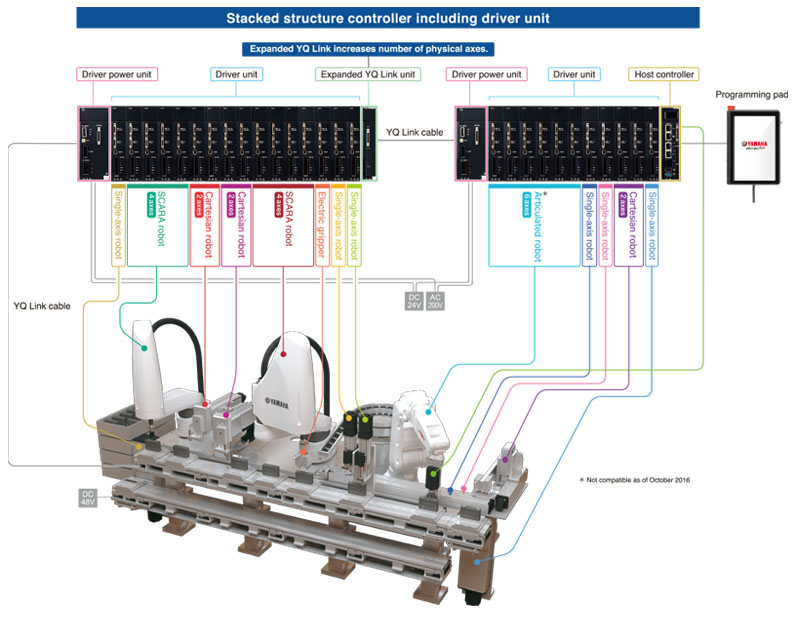

2,Improved automation: With 5G connectivity, industrial robots can seamlessly connect and communicate with other robotic systems, enabling enhanced coordination and collaborative tasks. This promotes greater automation and efficient operation of manufacturing processes.

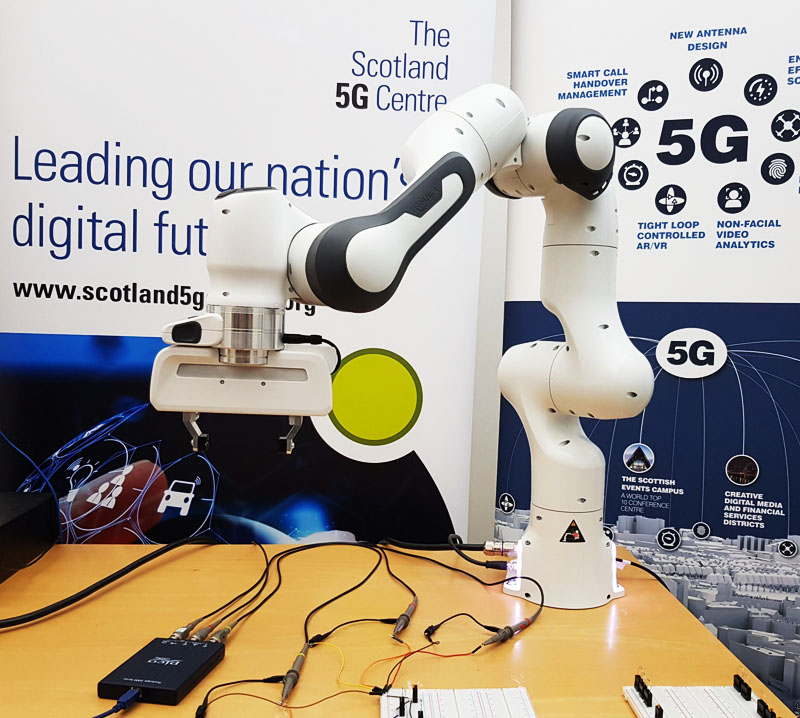

3,Remote control and monitoring: 5G enables real-time remote control and monitoring of industrial robots. Operators can remotely manage and monitor robot performance, diagnose issues, and make necessary adjustments, even from a distant location. This capability reduces downtime and enhances operational flexibility and efficiency.

Please Contact Us For Detailed Technical Parameters.

5g Industrial Robots Solution:

The implementation of 5G technology in the realm of industrial robots has revolutionized automation. With 5G in robotics, there are numerous use cases with remarkable benefits. For instance, the use of 5G in industrial robots enables real-time communication and coordination, enhancing their efficiency and productivity. Additionally, 5G in robotics offers a wide range of applications, including remote control and monitoring, enabling operators to manage robots from afar. Moreover, the deployment of 5GHz frequency in robot vacuums ensures a more reliable and stable connection, leading to improved cleaning performance. The convergence of 5G and robotics unlocks new possibilities, paving the way for advanced automation and optimization in diverse industries.